Fabrication and Testing on Rice Husks and Rice Starch Mixture as an Alternative Insulation Material

Summary

TLDRThe study explores the potential of rice husk and rice starch mixture as an eco-friendly and cost-effective alternative to conventional insulation materials for window-type air conditioning units. Through various tests, including ASTM standards and ANSYS simulation, the researchers found that a specific mixture (25% rice husk ash and 75% starch) demonstrated superior insulating properties with the lowest thermal conductivity. The study concludes that this sustainable material could be a viable option for thermal insulation, offering both environmental and economic benefits.

Takeaways

- 🌱 The study focuses on developing a sustainable and cost-effective insulation material using rice husk and rice starch for window type air conditioning units.

- 🌡️ Thermal insulation in air conditioning systems is crucial for reducing heat gain or loss, and the study aims to find an alternative to conventional materials like polyester, foam, and polyethylene foam.

- 🔍 The researchers are investigating the benefits of using rice husk as an insulating material due to its low thermal conductivity, which prevents heat from passing through easily.

- 🧪 The study will determine the properties of the rice husk and starch mixture, its advantages over commercial insulation materials, and the cost-effectiveness of the proposed material.

- 📊 The research has specific objectives, including fabricating and testing the new composite insulating material and determining its thermal properties using ASTM standards and ANSYS software.

- 🌐 The study's significance lies in maximizing the use of agricultural waste, such as rice husks, and analyzing its potential as an alternative insulation material for air conditioning units.

- 📚 The literature review highlights common problems with air conditioning insulation, such as wear and tear, and the importance of thermal conductivity and resistance in insulation materials.

- 🔧 The methodology involves treating raw rice husk, creating a mixture with rice starch and a foaming agent, and testing the resulting insulation boards for thermal properties.

- 📊 Experimental results showed that a specific mixture (Board D with 25% rice husk ash and 5% starch) had the lowest thermal conductivity, indicating better insulating properties.

- 💹 Cost analysis revealed that the proposed rice husk insulation boards are more economical compared to commercial polyethylene foam, making them a viable alternative.

- 🔬 ANSYS simulations were used to model the thermal conductivity of the rice husk-based insulation, validating the experimental results and providing additional insights into heat transfer.

Q & A

What is the main objective of the study presented in the transcript?

-The main objective of the study is to fabricate and test a mixture of rice husk and rice starch as an alternative insulation material for window type air conditioning units.

Why is there a need to develop alternative insulation materials for air conditioning units?

-There is a need to develop alternative insulation materials to address the crisis in sustainable growth and environmental stability, by creating cost-effective, durable, and lower embodied energy construction materials.

What are the common insulation materials used for air conditioning units?

-Common insulation materials used for air conditioning units include polyester foam, polyethylene foam, and rockwool.

What are the benefits of using rice husk as an insulation material?

-Rice husk has low thermal conductivity, which means it does not let heat pass through easily, making it an effective insulator.

What are the specific questions the study aims to answer?

-The study aims to answer questions such as the properties of the rice husk and starch mixture, the optimal ratio for the mixture, the advantages over commercial insulation materials, the cost of the proposed rice husk insulation, and the processes involved in achieving good insulation.

What are the general and specific objectives of the study?

-The general objective is to have an alternative insulation material, while the specific objectives include fabricating and testing the new composite insulating material, determining the capabilities of each thermal property using ASTM standard experimental setup and ANSYS software, and analyzing the effectiveness of rice husk ash as an insulator.

How does the study define thermal conductivity and thermal resistance?

-Thermal conductivity is defined as the ability of a material to conduct heat, while thermal resistance is the ability of a material to resist heat flow.

What are the methods used to determine the thermal properties in the study?

-The methods used to determine the thermal properties include ASTM E1461-13 for thermal diffusivity using the flash method, and ASTM C177-04 for thermal transmission properties using guarded hot plate apparatus.

What is the significance of the study in terms of resource utilization?

-The study aims to maximize the usage of rice husks, which are agricultural waste materials, by turning them into a valuable insulation material for air conditioning units.

What are the scope and limitations of the study?

-The study focuses on the analysis of the mixture of rice husk and rice starch as an insulation material for window type air conditioning units, and it does not extend to other types of air conditioning systems or insulation materials.

What are the conclusions drawn from the study regarding the effectiveness of the rice husk and starch mixture as an insulation material?

-The study concludes that the rice husk and starch mixture, specifically sample board D with 25% rice husk ash and 5% starch, has the lowest thermal conductivity and highest thermal resistivity, making it an effective and economical alternative to commercial insulation materials.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

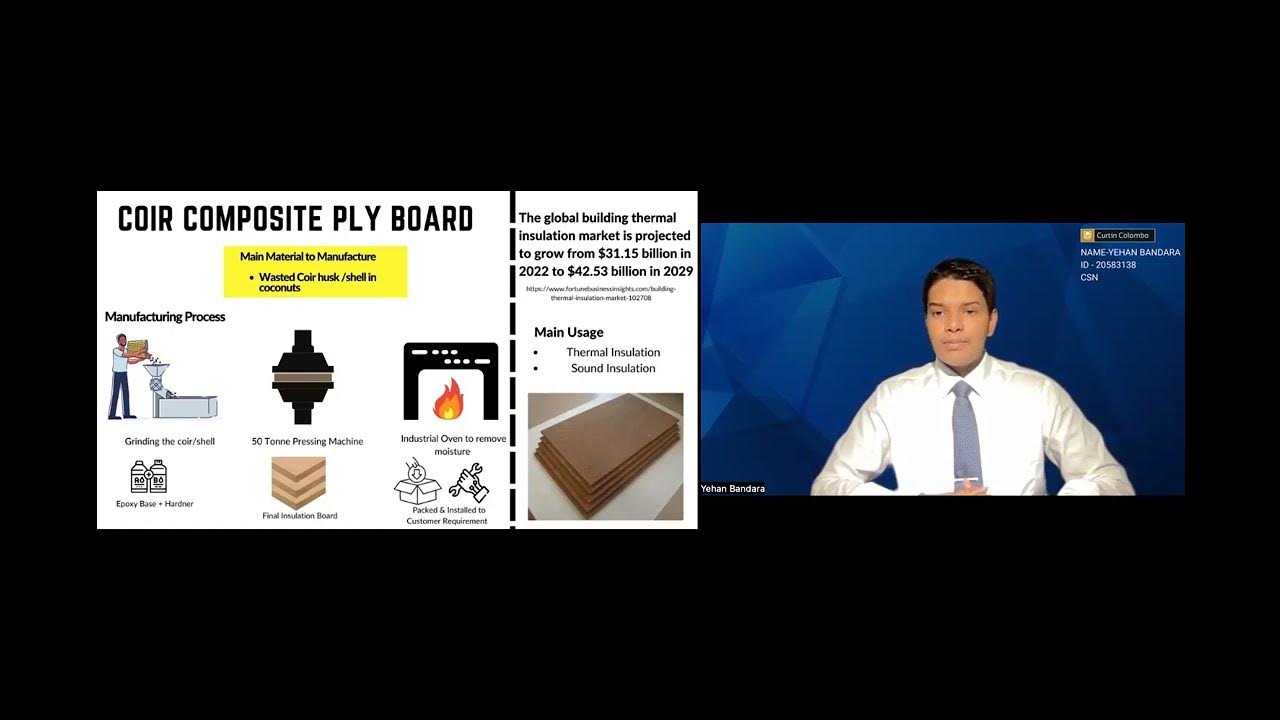

Coir Composite Board using wasted Coconut husk & Shells | MGMT 3000

Sizing an AC why we use Manual J , writesoft or simmilar

Natural Product : Bioetanol dari Singkong

#47 Mineral Admixtures | Agricultural Ashes | Part 2 Rice Husk Ash | Admixtures & Special Concretes

cara mudah membuat pupuk organik cair (POC) dgn hasil maksimal.

Warum nutzt keiner dieses super günstige Fenster Wärme UPGRADE? Nachgemessen!

5.0 / 5 (0 votes)