Value Stream Mapping Tutorial | Value Stream Mapping Symbols Explained | Invensis Learning

Summary

TLDRThis video script by George from Invensis Learning introduces Value Stream Mapping (VSM) as a lean tool for process analysis and improvement. It outlines the history, features, and benefits of VSM, highlighting its ability to identify waste and increase efficiency across various industries. The script guides viewers through creating a VSM, using symbols to represent processes, inventory, and information flow, and emphasizes the importance of analyzing and redesigning processes to minimize waste and maximize value for customers.

Takeaways

- 📈 Value Stream Mapping (VSM) is a lean tool that uses a flowchart to document every step in a process, identifying waste and opportunities for improvement.

- 🔍 VSM is a fundamental tool in lean management, helping to visualize production processes and increase value by identifying bottlenecks and eliminating waste.

- 🚀 VSM is part of the Six Sigma methodology for going lean, focusing on understanding value-added and non-value-added elements within a process.

- 🛠️ The script outlines eight types of waste, including defects, overproduction, waiting, non-utilized talent, transportation, inventory excess, motion excess, and excess processing, which are targets for elimination.

- 💡 Solutions to these wastes include clear operating procedures, reducing batch sizes, utilizing planning and scheduling tools, encouraging employee suggestions, and improving layouts to reduce unnecessary movement.

- 📚 The history of VSM is rooted in Toyota's lean manufacturing practices and was popularized by the book 'Lean Thinking', highlighting its importance in modern business practices.

- 🌟 Features of VSM include its ability to provide a comprehensive view of complex processes, identify areas for improvement, and track the actual system for further efficiency gains.

- 🏆 Advantages of VSM include its visual nature, ease of learning, identification of waste, improvement of cross-functional collaboration, and its applicability across various industries.

- 📝 When to use VSM includes situations such as designing a new manufacturing line, improving existing systems, and reducing unevenness in material and information flow.

- 📐 VSM symbols are essential for graphical representation, including process, material, information, and general symbols, which can be customized to fit organizational needs.

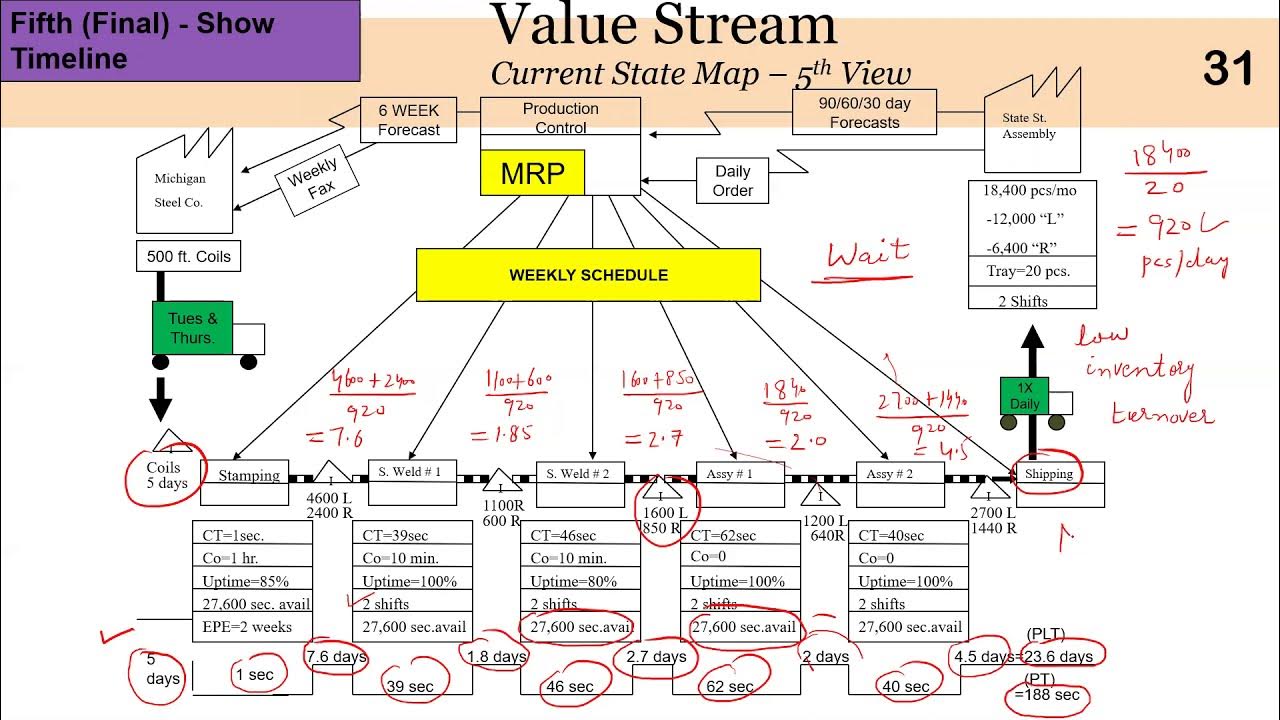

- 🛑 The steps to create a VSM include identifying the scope, mapping process steps, adding inventory and wait times, connecting processes, marking information flow, and creating a timeline to evaluate efficiency.

Q & A

What is Value Stream Mapping (VSM)?

-Value Stream Mapping is a lean management tool that uses a flowchart to document every step in a process, with the aim of identifying waste, reducing process cycle times, and implementing process improvements.

What is the primary purpose of Value Stream Mapping?

-The primary purpose of Value Stream Mapping is to visualize a production process, helping to increase the value of both product and service by identifying bottlenecks and eliminating waste.

What are the two key elements to understand in Value Stream Mapping?

-The two key elements to understand in Value Stream Mapping are value-added elements and non-value-added elements, which are essential for identifying and eliminating waste in a process.

What is the significance of the eight types of waste in the context of Value Stream Mapping?

-The eight types of waste are significant in Value Stream Mapping as they represent the areas where resources are being wasted and need to be addressed to improve efficiency and reduce non-value-added activities.

How can defects be reduced in a process according to the script?

-Defects can be reduced by having clear operating procedures or specifications, and by improving quality assurance steps through the use of automated systems or other new technologies.

What is the best way to eliminate overproduction as a type of waste?

-Overproduction can be eliminated by reducing large batches, building trusted supplier relationships, and using Value Stream Mapping and process mapping along with other analytical tools.

How does Value Stream Mapping help in improving cross-functional collaboration?

-Value Stream Mapping helps in improving cross-functional collaboration by providing a visual representation of the entire process, allowing teams from different functions to understand the process flow and identify areas for improvement collectively.

What is the historical background of Value Stream Mapping?

-Value Stream Mapping originated from Toyota as a minor tool and gained popularity with the spread of lean principles in the manufacturing industries of America. It was popularized by James Womack, Daniel Jones, and Daniel Roos through their book 'Lean Thinking'.

What are some of the main advantages of using Value Stream Mapping?

-Some main advantages of using Value Stream Mapping include visualizing end-to-end operations, identifying non-value-added elements termed as waste, improving cross-functional collaboration, defining bottlenecks and waste within the process, and being an inexpensive tool that can be easily critiqued by the workforce.

In what scenarios should a value stream map be created?

-A value stream map should be created when designing a new manufacturing line, improving an existing system, reducing unevenness in material and information flow, or whenever there is a need to update a process or reduce defects.

What is the importance of using symbols in Value Stream Mapping?

-Symbols in Value Stream Mapping are important as they provide a standardized way to represent different elements of the process, such as processes, inventory, information flow, and general connections, making the map easier to understand and analyze.

Can you provide an example of how Value Stream Mapping can be applied in a practical scenario?

-An example given in the script is a pizza maker shop where Value Stream Mapping is used to map out the process from adding toppings and baking to parceling and shipping the pizzas. It helps in visualizing the entire process, identifying waste, and improving efficiency.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

02_03_P2 Drawing the Current State Value Stream Map (VSM) - Acme Case Study

Value Stream Mapping (VSM) - Future State Map - Praktek Singkat (Part 2)

Process Mapping

Lean Construction Defined

⚙ Lean Manufacturing | A pursuit of perfection

What is Lean manufacturing? 5 functions of Lean Manufacturing | Lean Production

5.0 / 5 (0 votes)