Value Stream Mapping (VSM) - Future State Map - Praktek Singkat (Part 2)

Summary

TLDRThis video explains the process of Value Stream Mapping (VSM) for continuous improvement in manufacturing. It walks through the PDCA cycle, starting with defining product families and mapping the current state. Key steps include conducting Gemba walks to observe areas like cutting, stamping, molding, and warehouse, and applying Kanban systems and inventory management to improve flow. The video emphasizes the importance of standardizing processes, improving material handling, and reducing cycle times. It concludes with steps for monitoring, auditing, and ensuring the success of VSM projects for long-term efficiency gains.

Takeaways

- 😀 The video explains the concept of Value Stream Mapping (VSM) and how it plays a role in continuous improvement using the PDCA cycle.

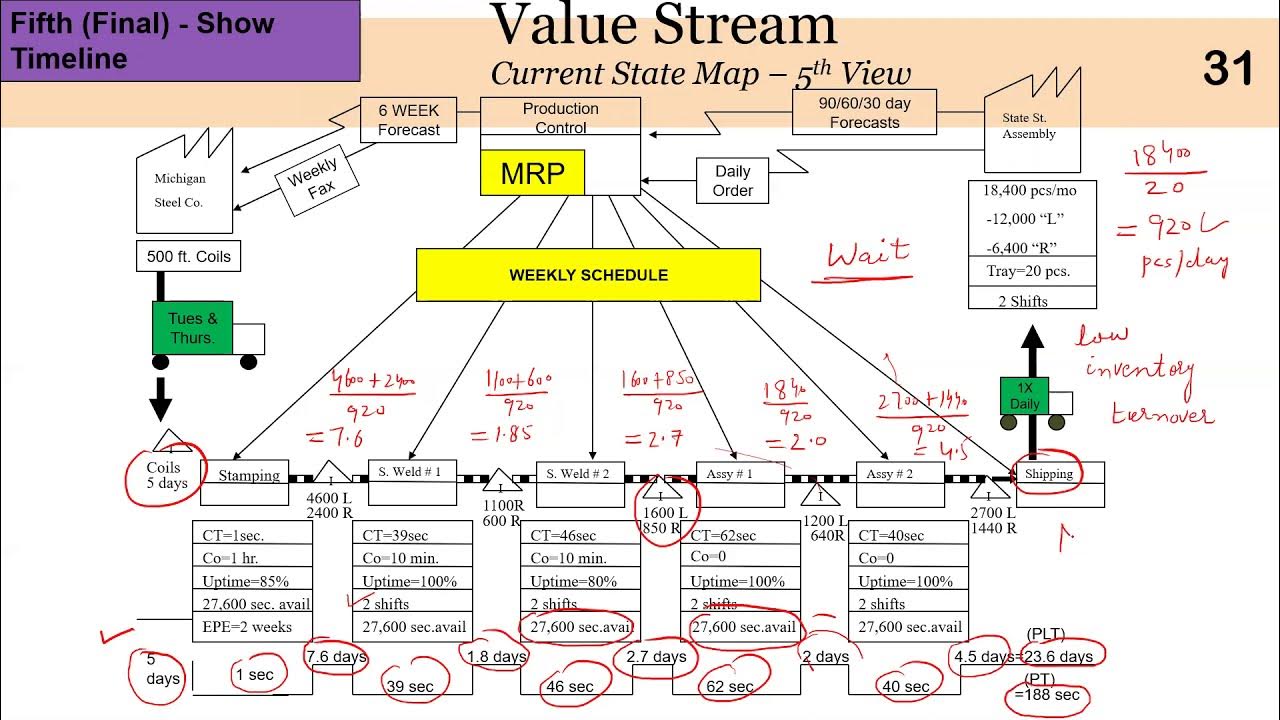

- 😀 The process starts with selecting a product family and then gathering data to create the current state map (Karen state map).

- 😀 A key part of VSM is conducting a 'Gemba' walk, where the team observes the actual processes in the factory to identify opportunities for improvement.

- 😀 The Gemba walk is a long-term project, typically lasting from one day to one week, requiring detailed observations for future improvements.

- 😀 In the 'cutting' area, inventory should be controlled using a supermarket system, ensuring continuous flow without any disruptions.

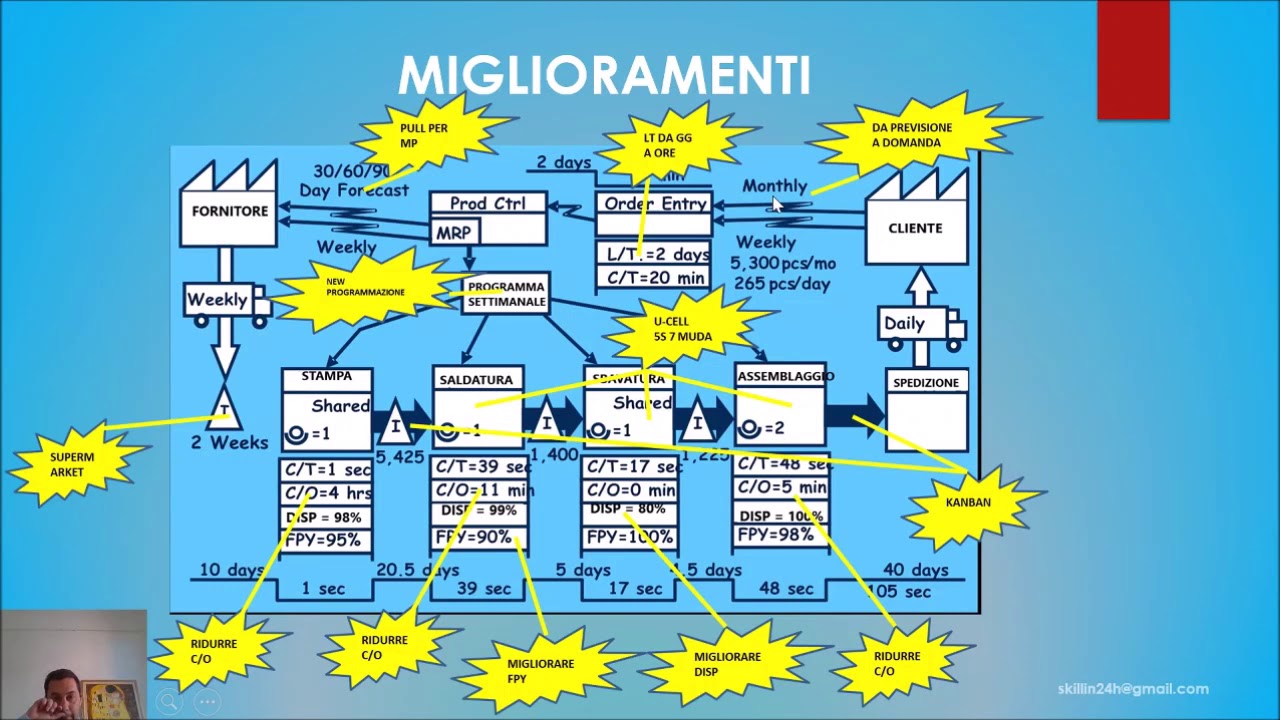

- 😀 The 'kanban' system should be implemented to control material flow, where orders are made based on supermarket demand, reducing push production.

- 😀 In the 'samping' area, inventory should also be controlled via supermarkets, with standardized material handling to ensure smooth operations.

- 😀 In the 'warehouse' area, inventory should be reduced, with a target to decrease the stock from 480,000 pieces to 250,000 pieces, optimizing space and efficiency.

- 😀 The 'moulding and stamping' areas should focus on integrating processes to eliminate inventory and improve machine efficiency, targeting reduced manpower and cycle times.

- 😀 After creating the current state map, the next step is to calculate the target lifetime and processing times for each area, based on cycle times and improvements made.

Q & A

What is the definition of value stream mapping (VSM)?

-Value stream mapping (VSM) is a lean management technique used to analyze and design the flow of materials and information required to bring a product or service to a consumer. It helps identify areas for improvement and optimize processes.

What is the first step in creating a value stream map (VSM)?

-The first step in creating a value stream map (VSM) is determining the product family, which involves selecting the products to be analyzed for the mapping process.

What is the importance of the 'Gemba' in value stream mapping?

-The term 'Gemba' refers to the practice of going to the actual place where value is created, in this case, the manufacturing floor. It is essential for gathering real-time data, observing the processes, and identifying improvement opportunities directly at the source.

How long does a Gemba walk usually last in the context of value stream mapping?

-A Gemba walk for value stream mapping typically lasts between one day to one week, depending on the complexity and the scope of the project.

What is the role of the Kanban system in value stream mapping?

-The Kanban system is used to control the flow of materials and ensure that inventory levels are managed effectively. It replaces traditional push systems with a pull-based approach, ensuring that production is driven by actual demand.

How does the supermarket system help in value stream mapping?

-The supermarket system is used to manage inventory in a way that prevents overproduction. It acts as a buffer between different stages of production, ensuring that material flow is continuous and inventory levels are controlled.

What are the key improvements proposed in the transcript regarding the cutting area?

-The proposed improvements in the cutting area include replacing uncontrolled inventory with a supermarket system and implementing a Kanban system for ordering and controlling material flow.

What is the target for reducing inventory in the warehouse, according to the script?

-The target is to reduce inventory in the warehouse from 480,000 pieces to 250,000 pieces, which would help streamline operations and reduce storage costs.

What is the significance of standardizing material handling in the stamping area?

-Standardizing material handling in the stamping area ensures that the process of delivering materials to the warehouse is efficient and consistent, reducing variability and improving overall workflow.

What is the final step in the PDCA cycle after implementing improvements in value stream mapping?

-The final step in the PDCA cycle is 'Act', which involves summarizing the results of the project, standardizing processes, sharing best practices, and conducting regular audits to maintain improvements and continue identifying new areas for enhancement.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Value Stream Mapping Tutorial | Value Stream Mapping Symbols Explained | Invensis Learning

02_03_P2 Drawing the Current State Value Stream Map (VSM) - Acme Case Study

Lezione 4D - CREAZIONE VSM - Parte 4 di 4 - Lean Thinking e Toyota Producition System - Zero sprechi

⚙ Lean Manufacturing | A pursuit of perfection

Strategi Proses Bab 7 || Manajemen Operasional

Operations Management Chpt. 7 Palmer

5.0 / 5 (0 votes)