Sollecitazioni meccaniche (parte 1)

Summary

TLDRThis video introduces key concepts in mechanical testing, focusing on elastic and plastic deformation. It explains the stress-strain relationship through a graphical representation, highlighting important points like the yield point and ultimate stress. The speaker discusses material behavior under load, emphasizing the need for safety factors in design to prevent failure. Additionally, fatigue failure is addressed, outlining how repeated loading can lead to unexpected material failure. Practical examples and calculations are provided to illustrate these principles, setting the stage for further exploration in mechanical testing and materials science.

Takeaways

- 😀 Mechanical tests are crucial for understanding material properties like deformation.

- 🛠️ Deformation can be elastic (temporary) or plastic (permanent), impacting design decisions.

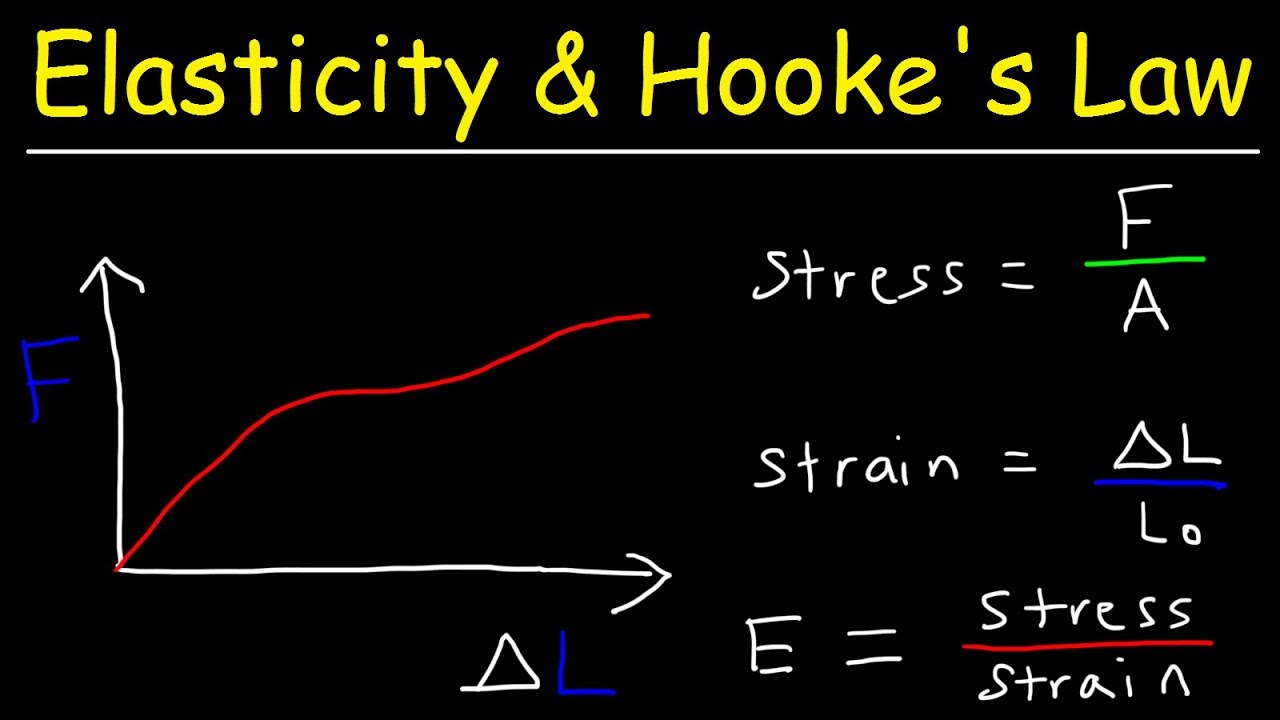

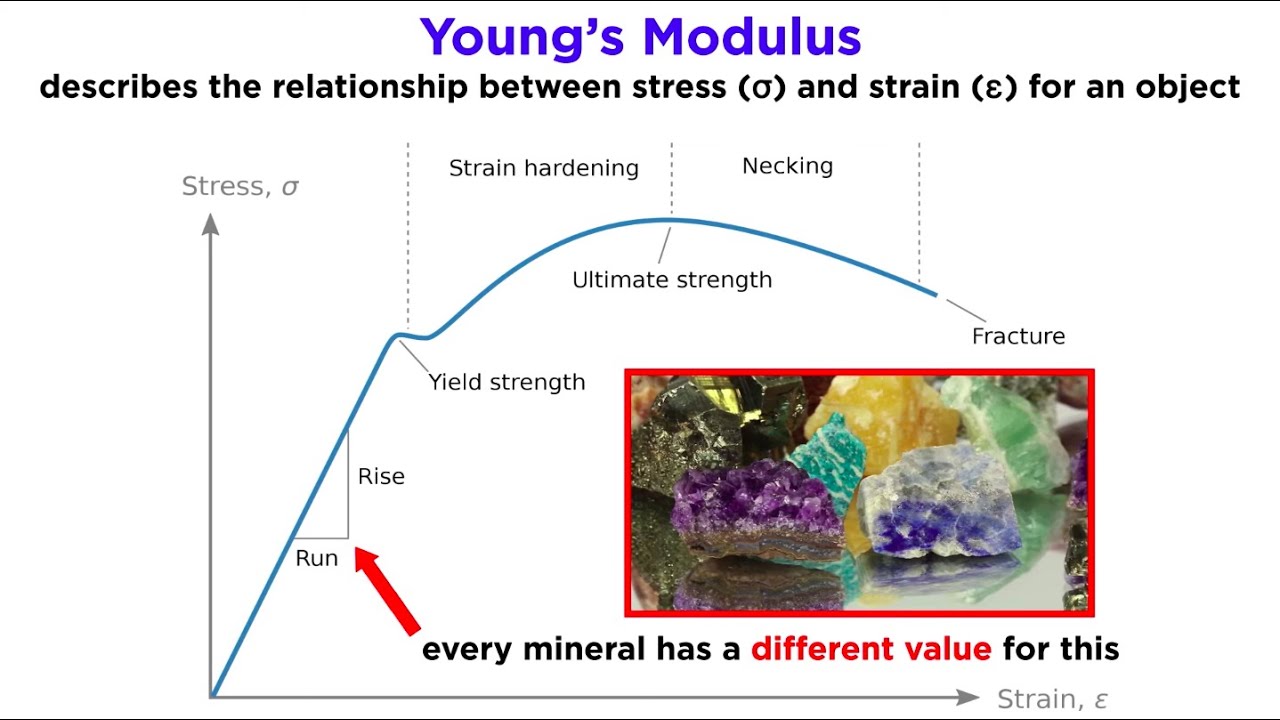

- 📊 The stress-strain curve is fundamental for analyzing material behavior under load.

- ⚖️ The yield point marks the transition from elastic to plastic deformation.

- 🚨 Maximum stress (ultimate strength) is the highest load a material can withstand before failure.

- 📏 Elasticity is defined by Hooke's Law, relating stress to strain in the elastic range.

- 🔍 The allowable stress for design must be below the material's rupture strength for safety.

- ⚙️ Fatigue failure occurs due to repeated stress cycles, often without visible deformation.

- 💡 Understanding load conditions is key for determining the fatigue limit of materials.

- 🔄 Future videos will cover more on tensile, compressive, and torsional tests.

Q & A

What are the two main types of deformation discussed in the video?

-The two main types of deformation are elastic deformation, which is temporary and allows the material to return to its original shape after load removal, and plastic deformation, which is permanent and leaves the material deformed.

How is stress defined in mechanical testing?

-Stress (σ) is defined as the force (F) applied per unit area (A) of the material, expressed as σ = F / A.

What is the significance of the yield point in the stress-strain curve?

-The yield point marks the transition from elastic to plastic deformation, indicating the maximum stress a material can withstand without permanent deformation.

What is meant by ultimate tensile strength?

-Ultimate tensile strength is the maximum stress that a material can endure before it fails or fractures.

What is Hooke's Law and how is it applied in the context of material testing?

-Hooke's Law states that within the elastic limit of a material, the stress is directly proportional to the strain, expressed as σ = E · ε, where E is the modulus of elasticity.

Why is it important to consider safety factors in material design?

-Safety factors are important to ensure that the material operates within safe limits, preventing failure under unexpected loads. It typically involves using an allowable stress that is a fraction of the material's ultimate strength.

What is fatigue failure and how does it differ from other types of failure?

-Fatigue failure occurs when a material fails due to repeated loading and unloading cycles, often without significant visible deformation prior to failure, distinguishing it from other types of failure that may show signs of stress or deformation.

How can the cross-sectional area and diameter of a specimen be calculated?

-The cross-sectional area can be calculated using the formula A = F / σ, and once the area is known, the diameter can be found using the formula d = √(4A / π).

What factors influence the fatigue limit of a material?

-The fatigue limit is influenced by the type of loading conditions, the material properties, surface finish, and the presence of any defects or notches in the material.

What topics will future videos cover related to mechanical testing?

-Future videos will cover more detailed aspects of mechanical testing such as torsion, compression, and cutting, along with additional exercises to reinforce understanding.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Pitch sobre Critérios de Escoamento de Metais Dúcteis

PG 04 A - Stress Strain

Elasticity & Hooke's Law - Intro to Young's Modulus, Stress & Strain, Elastic & Proportional Limit

Elasticity

Yield Strength and Resilience of Materials | Basic Concepts | Materials Science And Engineering

Overview of Geologic Structures Part 1: Rock Deformation, Stress and Strain

5.0 / 5 (0 votes)