Mig Welding Basics part 5 - Practice

Summary

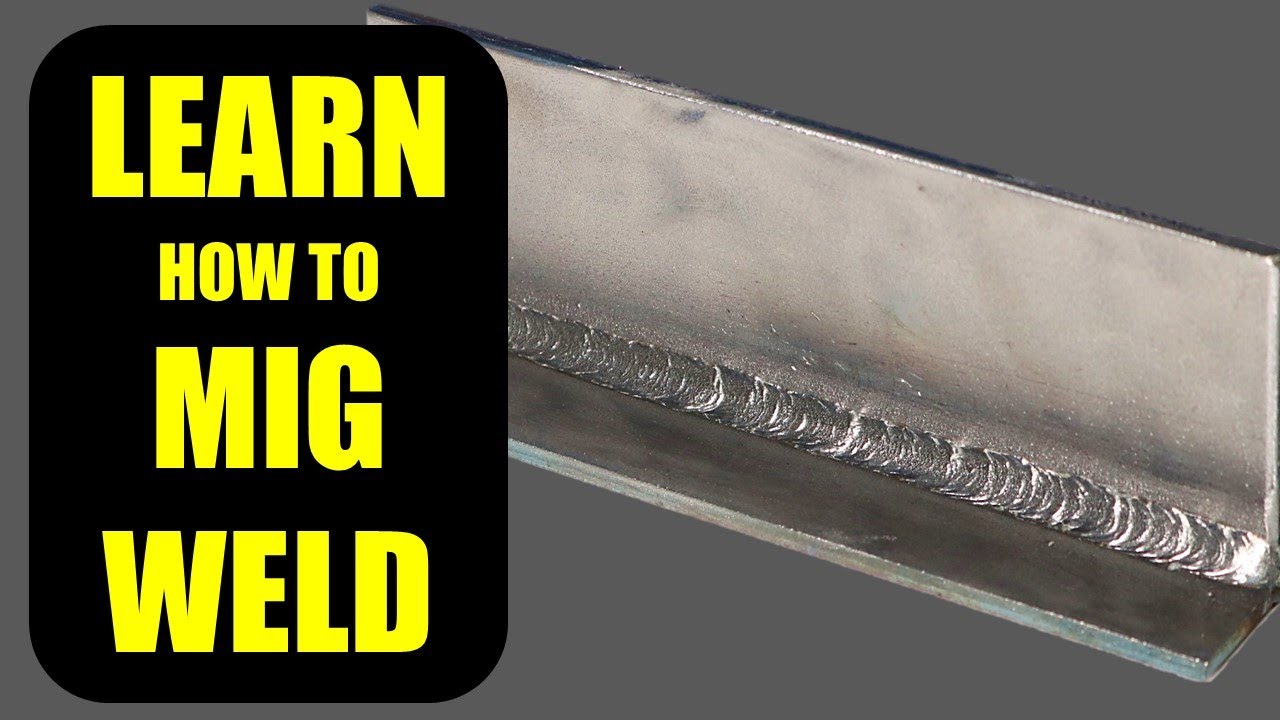

TLDRIn this segment of MIG welding basics, the focus is on mastering the technique of running a consistent bead, essential for successful welding. The instructor highlights the importance of practice using different metal thicknesses and suggests sources for practice materials, including the James F. Lincoln Foundation. Key techniques discussed include maintaining a steady hand, adjusting machine settings based on wire thickness, and the significance of stick-out distance for various materials. Viewers are encouraged to experiment with their techniques and subscribe for more valuable welding tips.

Takeaways

- 😀 Running a good bead is essential in MIG welding and forms the foundation for all future welding skills.

- 😀 Practicing consistently on various materials, such as 11 gauge and thinner gauges, helps improve technique and consistency.

- 😀 The James F. Lincoln Foundation offers affordable metal project kits for practice, making it easier to access materials.

- 😀 Proper wire preparation is crucial; always snip the wire end to avoid poor starts and ensure smooth welding.

- 😀 Propping the welding gun is important for stability, allowing for better control and a more consistent bead.

- 😀 Practice involves running beads along marked lines to develop accuracy and control over the weld puddle.

- 😀 The technique for stacking beads (padding) involves overlapping each bead halfway with the next to create a strong weld.

- 😀 Wire feed speed needs to be adjusted based on the thickness of the metal and the size of the welding wire used.

- 😀 Stick out—the distance from the contact tip to the puddle—is crucial for maintaining the right arc characteristics.

- 😀 Longer stick outs can be advantageous for welding thin sheet metal, allowing for better puddle control and penetration.

Q & A

What is the primary focus of this segment on MIG welding?

-The primary focus is on practicing how to run a good bead, which is essential for effective MIG welding.

Why is running a good bead considered foundational in MIG welding?

-A good bead serves as the backbone of all welding techniques; without it, the quality of further welding work may be compromised.

What are some recommended sources for obtaining practice metal?

-Practice metal can be sourced from scrap yards, local businesses selling drop pieces, or through the James F. Lincoln Foundation, which offers affordable project kits.

What tool does Jod use to improve his wire feed speed accuracy?

-He uses a digital meter that converts the rotational speed of the wire feed into linear speed in feet per minute.

What technique does Jod suggest for ensuring a good start when welding?

-He suggests snipping the wire end before starting to prevent poor starts caused by a ball forming on the wire.

How does Jod recommend maintaining stability while welding?

-He recommends propping the welding gun with a hand or finger against a rigid surface to ensure better control and stability.

What is the significance of the soapstone lines marked on the metal?

-The soapstone lines serve as guides for running straight beads, helping welders maintain accuracy.

What adjustments does Jod make when moving from welding thicker to thinner materials?

-He adjusts the machine settings to lower wire feed speeds and changes techniques to accommodate the differences in thickness, such as switching to downhill welding for thinner metals.

What is the recommended stick out length for short-circuit MIG welding?

-Typically, the stick out should be kept below 1/8 inch to achieve optimal welding results.

How can adjusting the contact tip help when welding thicker materials?

-Trimming the contact tip can help achieve a shorter stick out, which enhances arc force and improves the quality of the weld.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Welding Basics for Beginners

How to MIG Weld for Beginners: MIG Welding Basics

VIDEO 3 Prinsip Pembuatan Jalur Las Downhand SMAW

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

Mig Welding Basics 4 - Avoiding LOF - Ice Bucket Words

DASAR-DASAR & PENGERTIAN SEMUA JENIS TIPE PENGELASAN UNTUK PEMULA

5.0 / 5 (0 votes)