MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

Summary

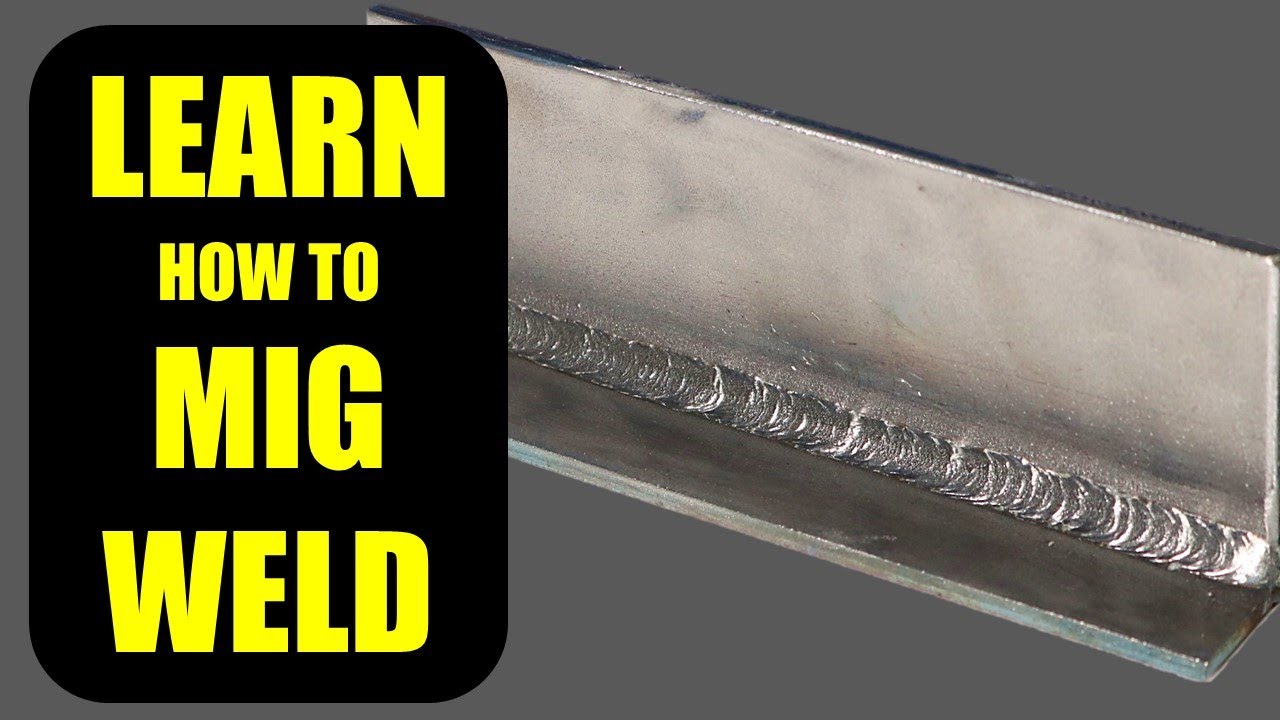

TLDRIn this MIG welding tutorial, the speaker walks viewers through the basics of MIG welding, covering machine setup, wire speed, voltage adjustments, and common welding mistakes. Through demonstrations, the speaker shows how to identify and fix issues with welds, such as too much or too little wire speed, and explains various welding techniques, including whip-and-pause and straight welds. Emphasizing the importance of correct machine settings and providing useful tips for beginners, the tutorial ensures that viewers can troubleshoot and create strong, clean welds with confidence.

Takeaways

- 😀 Make sure to understand how to set up your MIG welder, including wire speed and voltage adjustments, to ensure successful welds.

- 😀 Wire speed is crucial: too slow creates sizzle and burnback, too fast leads to spatter and poor quality welds.

- 😀 The perfect MIG welding sound resembles sizzling bacon in a hot pan, indicating the right settings.

- 😀 If the wire burns back onto the tip, it often indicates insufficient wire speed or improperly adjusted drive rollers.

- 😀 A good MIG weld should be consistent and flat, with the metal flowing out smoothly and evenly along the edges.

- 😀 Always start with a baseline wire speed and voltage and fine-tune the machine settings based on the sound and appearance of your weld.

- 😀 Different welding techniques, such as whip and pause, straight pushing, and circles, can be used to create various bead profiles.

- 😀 MIG welding in different positions (horizontal, vertical, and overhead) requires adjusting your technique and machine settings.

- 😀 Overhead welding can be easier than expected if settings are correct, though it may result in more sparks.

- 😀 For vertical down welding, it’s better to push the weld downward, staying ahead of the puddle, to ensure proper penetration and avoid weak welds.

- 😀 Machine settings are vital to good welding results. Tightening the drive rollers and ensuring proper wire size are also key factors to watch out for.

Q & A

What is MIG welding and why is it important to learn?

-MIG welding (Metal Inert Gas welding) is a widely used welding technique that is essential for various applications. It's particularly useful for beginners due to its ease of use. Learning it can help in making strong, consistent welds, especially in the automotive and structural industries.

What are the key settings to adjust when setting up a MIG welder?

-The main settings to adjust on a MIG welder are wire speed and voltage. The wire speed controls how much wire is fed into the weld, while the voltage controls the heat output. Getting these settings right is crucial for a good weld.

How can you tell if the wire speed is incorrect?

-If the wire speed is too low, you’ll hear a slower, sizzling sound. If it’s too high, the machine will produce a 'machine gun' noise, with excessive spatter and possible burn-back of the wire to the tip.

What should you listen for to know if your MIG welder is set correctly?

-You should aim for the sound of bacon frying, which indicates that the wire speed and voltage are properly adjusted. A consistent and smooth sizzling sound suggests that the weld is being created correctly.

What happens if the wire speed is too high?

-When the wire speed is too high, you’ll hear a machine-gun-like noise, and the machine will deposit more metal than the voltage can handle. This leads to excess spatter, poor penetration, and an uneven weld.

Why is it important to adjust the wire tension inside the welder?

-The wire tension needs to be adjusted to ensure the drive rollers push the wire consistently. If the rollers are too loose, the wire may slip, leading to inconsistent wire feeding and poor weld quality.

What are the different welding positions, and how do they affect the weld?

-Welding positions include horizontal, vertical, and overhead. Horizontal is the most common, while vertical and overhead positions require more skill. Welding in these positions can be tricky, but with proper technique, they can still produce strong welds.

What is the 'whip and pause' technique in MIG welding?

-The 'whip and pause' technique involves moving the torch forward to burn the weld and then pulling back slightly to fill the gap. This technique helps with heat control and consistency, especially when welding thicker materials.

What are the advantages of using 0.030 wire in MIG welding?

-0.030 wire is a versatile choice for MIG welding, as it works well for both sheet metal and structural work. It provides a good balance of penetration and ease of use for most welding tasks, making it a popular choice among beginners.

How does the choice of gas mix affect MIG welding?

-The gas mix controls the shielding of the weld. A common mix is 75% CO2 and 25% Argon, which provides a good balance for most welding tasks. Different gas mixes can affect the weld’s appearance, penetration, and spatter.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

MIG Welding Basics For Beginners

Mesin Las GMAW 350 Dari FOCUS : Pilihan Yang Tepat Untuk Pengelasan Profesional

Belajar Pengelasan MIG tanpa Gas Tambahan CO2 | ( FLUX CORE ) | IZUMI MIG 130

Welding Basics for Beginners

Mig Welding Basics part 5 - Practice

How to MIG Weld for Beginners: MIG Welding Basics

5.0 / 5 (0 votes)