Chemistry Sugar Cane

Summary

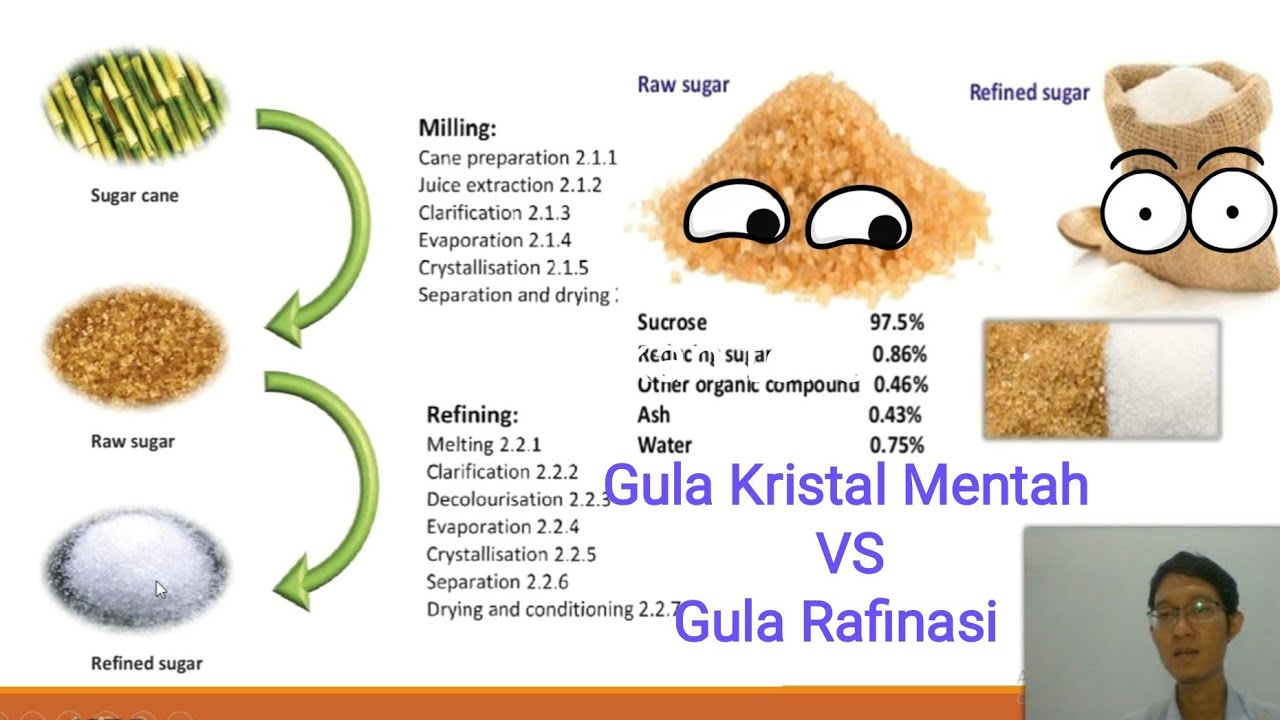

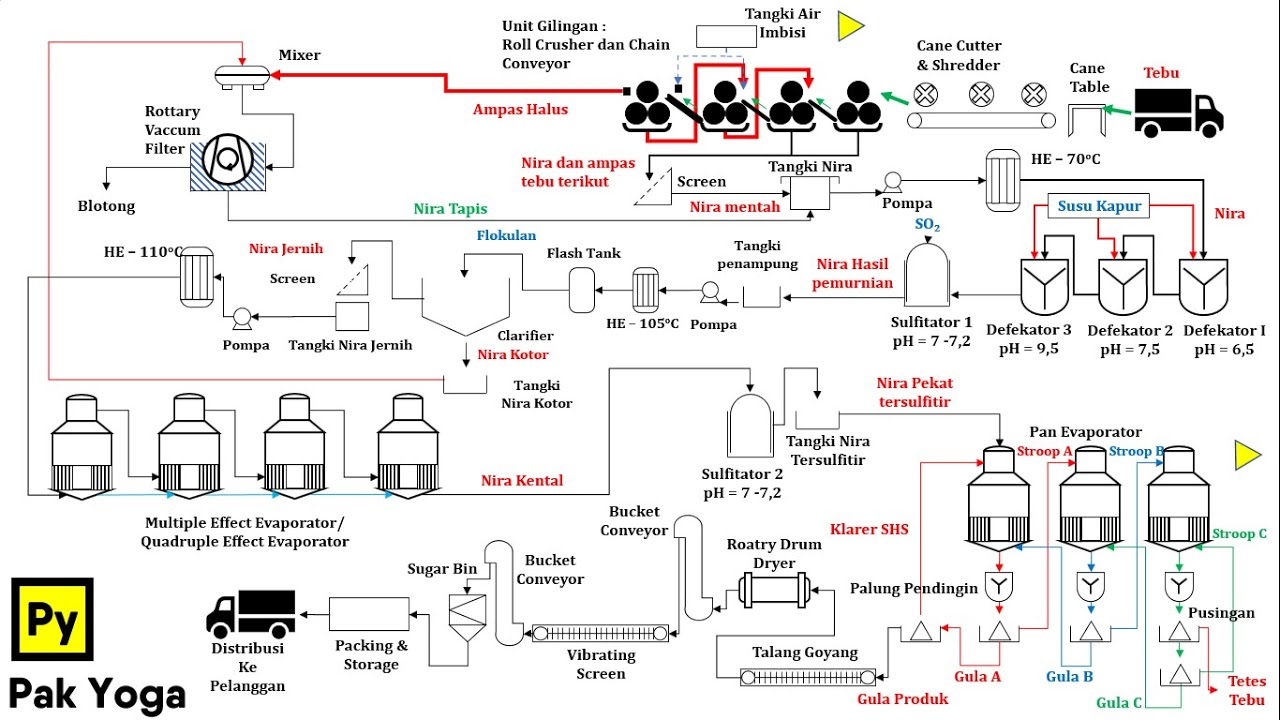

TLDRThe video explains the sugar extraction process from sugarcane, a grass that can grow up to five meters tall and contains 11-15% sucrose. It details the journey from harvesting to juice extraction in factories, emphasizing the importance of timely processing to prevent yield loss. The juice undergoes various purification stages, including defecation, carbonation, and sulphatation, resulting in clarified juice. This juice is evaporated and concentrated to form sugar crystals, which are separated from molasses, a byproduct used in alcohol production and animal feed. The video highlights the intricate methods involved in sugar manufacturing.

Takeaways

- 🌱 Sugar is extracted from sugarcane, a member of the grass family, which grows 3 to 5 meters tall.

- 🍬 Sugarcane contains about 11 to 15 percent sucrose by weight and is primarily used in India for sugar production.

- 🏭 Harvested sugarcane must reach factories within 24 hours to prevent loss of sugar yield.

- 💧 In factories, the cane is washed and chopped, and juice is extracted using roll crushers with added water.

- ♻️ The spent cane, known as baggage, is a byproduct used as fuel for electricity production.

- 🔬 The extracted juice contains impurities and is slightly acidic, which can lead to sugar loss through hydrolysis.

- ⚗️ Defecation is the process of adding lime to the juice to precipitate impurities and neutralize acidity.

- 💨 Carbonation and sulphatation are processes that further purify the juice by removing excess lime and traces of sulfur.

- 🥫 The purified juice, known as clarified juice, is concentrated by evaporation to remove most of its water content.

- 🍯 Sugar crystals form in vacuum pans from concentrated juice, and centrifugation separates these crystals from the liquid.

- 🍂 The leftover thick black liquid, molasses, is a byproduct containing sucrose, glucose, and fructose, used in alcohol production and animal feed.

Q & A

What is sugar extracted from?

-Sugar is primarily extracted from sugarcane and beetroot.

How tall can sugarcane grow?

-Sugarcane can grow up to a height of three to five meters.

What percentage of sucrose does sugarcane contain by weight?

-Sugarcane contains about 11 to 15 percent sucrose by weight.

Why is it important for harvested sugarcane to reach factories quickly?

-If there is any delay in reaching the factory, it causes a loss of sugar yield.

What is the first step in processing sugarcane at the factory?

-The first step is washing the cane to remove mud, followed by chopping it into pieces.

What is the role of lime (Ca(OH)₂) in sugar processing?

-Lime is added to precipitate impurities and to neutralize the slightly acidic juice.

What is press mud, and why is it significant?

-Press mud is the precipitate from the defecation, carbonation, and sulphitation processes, and it is useful as manure.

What happens to the clarified juice during processing?

-The clarified juice, which contains 85 percent water, is evaporated to approximately 40 percent water.

What by-product is formed after separating sugar crystals from the thick black liquid?

-The thick black liquid obtained after separation of crystals is called molasses.

What are the uses of molasses?

-Molasses contains 50 percent sucrose and is used in the manufacture of alcohol by fermentation and as an animal feed supplement.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Ekstraksi Tebu menjadi Nira - Diagram Alir Proses Industri Gula (part 1/4)

CSEC Chemistry: Extracting Sucrose from Sugarcane

Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

Abaca Fiber Production Process in Antique

Perbenihan Tebu Sistem Budchips

LAPTOP SI UNYIL - KARET DI SEKITAR KITA (11/1/17) 3-2

5.0 / 5 (0 votes)