Let's build a 3-pole DC motor that's self-starting (Motors #2)

Summary

TLDRIn this video, we build a 3-pole DC motor, improving upon a previous 2-pole design. The main upgrades address issues like brush sparking and the motor's inability to self-start. By switching to carbon brushes, enhancing the commutator, and adjusting the magnetic flux, the new motor starts automatically and runs smoother. The video also demonstrates the impact of using a capacitor in parallel with the battery to provide the extra torque needed for startup. The final motor performs better and more efficiently, with the brushes only wearing out over time, typical of brushed DC motors.

Takeaways

- 😀 The 2-pole DC motor from the previous video had issues with brush sparking and self-starting, which were identified as areas for improvement.

- 😀 The main problem with the 2-pole motor was the sparks caused by the brushes, leading to oxidation, which could cause the motor to stop working over time.

- 😀 To fix the sparking issue, the new motor design uses carbon or graphite brushes, which are much better for maintaining electrical contact than metal brushes.

- 😀 Another problem with the 2-pole motor was that it wasn't self-starting; the brushes lose contact with the commutator at 90-degree rotation, causing a lack of torque.

- 😀 The 3-pole motor design improves self-starting capability by ensuring at least two of the three commutator segments are always in contact with the brushes.

- 😀 The 3-pole motor uses a similar base design as the 2-pole motor but with a new commutator made from 13mm of plastic tube and 23mm of copper pipe cut into four strips.

- 😀 Epoxy putty is used to secure the commutator and shaft, ensuring everything stays in place while the epoxy dries.

- 😀 The motor uses 28-gauge wire with 200 turns per pole, which helps provide sufficient torque despite the lower efficiency of a 3-pole design compared to a 2-pole one.

- 😀 Carbon brushes, costing only 15 cents each, are attached to stainless steel strips with epoxy putty, simplifying the design without needing springs.

- 😀 To help with magnetic flux distribution, the magnet holders are replaced by a single arch-shaped structure that makes the rotor turn smoothly even when no power is applied.

- 😀 When tested with a DC power supply, the 3-pole motor starts spinning immediately, and its speed can be adjusted by increasing the voltage or reversing the polarity.

- 😀 Using a 9V battery, the motor requires a head start to spin, as the battery can't provide enough current for the torque needed to start the motor on its own.

- 😀 A 100 microfarad electrolytic capacitor is added in parallel with the battery to help start the motor, ensuring it has enough current when turned on.

- 😀 Capacitors are commonly used in motors to help provide the necessary current for starting, which is why many commercial motors have capacitors installed alongside them.

Q & A

What is the main improvement being made in this 3-pole motor compared to the 2-pole motor?

-The main improvement is that the 3-pole motor solves the issue of the brushes losing continuous contact with the commutator, making it self-starting. This allows the motor to run smoothly without requiring a manual spin to start.

Why do the brushes in the 2-pole motor cause oxidation over time?

-The brushes in the 2-pole motor were made of metal, which creates sparks when in contact with the commutator. These sparks cause oxidation, and the oxide formed does not conduct electricity, which could lead to the motor failing if the oxidation buildup interrupts the electrical contact.

What material will be used for the brushes in the 3-pole motor, and why is it a better choice?

-The 3-pole motor will use carbon or graphite brushes, which are much better materials for making contact with copper than metal brushes. Graphite is a good conductor and reduces the chances of oxidation, ensuring better motor performance and longer lifespan.

Why was the 2-pole motor not self-starting?

-The 2-pole motor wasn't self-starting because the brushes were not in continuous electrical contact with the commutator. Once the motor rotated 90 degrees, the brushes lost contact, cutting off current flow and stopping the motor from producing torque until the brushes made contact again.

What change in design is made in the 3-pole motor to ensure it is self-starting?

-The 3-pole motor ensures continuous brush contact by having three poles instead of two. This means at least two of the three commutator segments are always in contact with the brushes, providing constant torque and enabling the motor to start automatically.

How will the commutator be constructed in the 3-pole motor?

-The commutator in the 3-pole motor will be constructed using a plastic tube and copper pipe. The copper pipe will be cut into four equal strips, with three of them used to form the commutator segments. Epoxy putty will be used to secure the shaft and commutator in place.

Why is thinner wire being used in the 3-pole motor compared to the 2-pole motor?

-Thinner wire (28 gauge) is being used in the 3-pole motor to ensure sufficient torque. Although a 3-pole motor is slightly less efficient than a 2-pole motor, the goal is to prioritize torque over speed. Using thinner wire with 200 turns per pole achieves this balance.

How does the change in magnet holders improve the performance of the 3-pole motor?

-The magnet holders in the 3-pole motor are replaced with a large arch design. This helps to spread out the magnetic flux lines, which reduces the attraction between the magnets and the armature's stainless steel parts, resulting in smoother rotor movement and improved performance.

Why does the motor require more torque to start when powered by a 9V battery?

-The motor requires more torque to start with a 9V battery because the battery cannot provide enough current at the given voltage. More torque requires a higher current, and the battery's limited current output prevents the motor from starting without assistance.

How does the addition of a capacitor help the 3-pole motor start with a 9V battery?

-The addition of a 100 microfarad electrolytic capacitor helps the motor start by charging up to 9V when the motor is off. When the motor is turned on, the current flows from the capacitor instead of the battery, allowing the motor to receive the necessary torque to start.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Let's measure the torque of a DC motor (Motors #3)

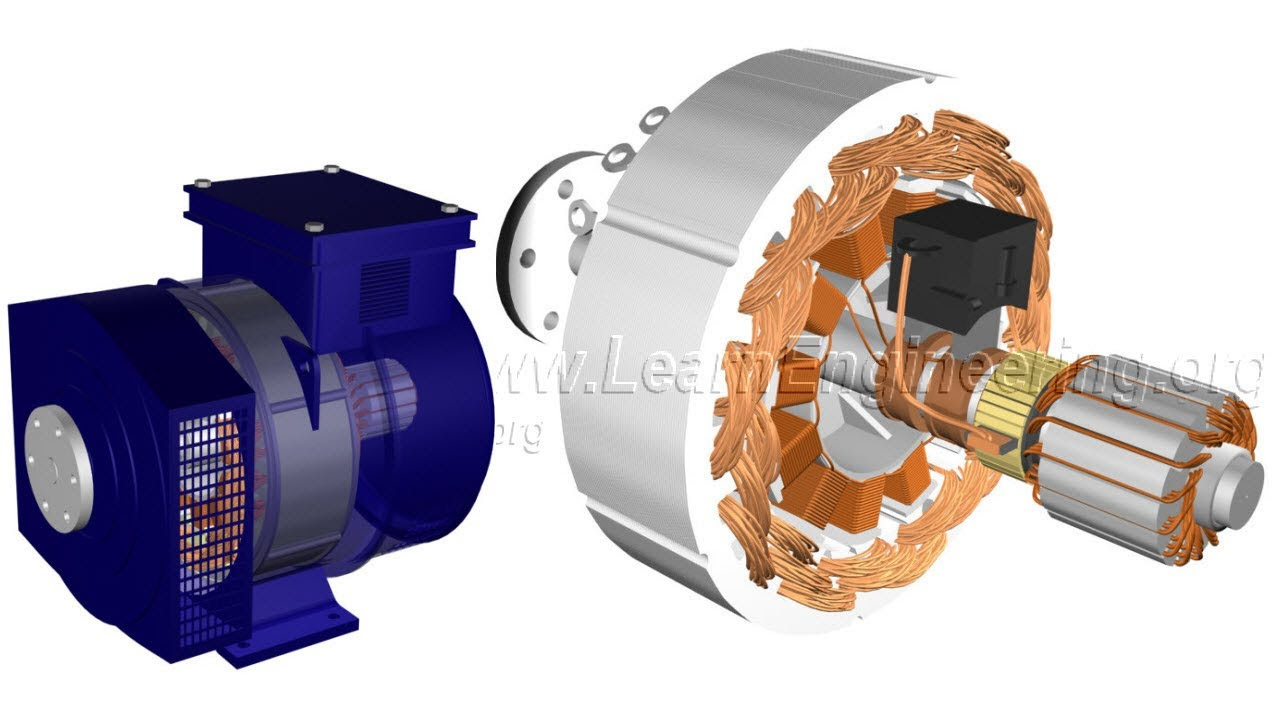

Cara Desain Dinamo - (Motor Induksi 3 Fasa)

How does an Alternator Work ?

Getting to Know The PowerFlex 525 - Connected Components Workbench

Fuzzy Logic Examples | Fuzzy Logic Part 3

The ULTIMATE Running Belt Showdown: Which One Will You Choose? | Run4Adventure

5.0 / 5 (0 votes)