PFDs: Reactors Towers Vessels Part 2

Summary

TLDRIn this lecture, Marina Miletic introduces the key symbols and equipment representations used in process flow diagrams (PFDs). She explains the differences between various types of vessels, such as accumulators and flash tanks, detailing their function in process units and separation processes. The lecture also covers common valve types like ball, gate, and globe valves, as well as their role in controlling flow. Additionally, the symbols for storage tanks and the importance of accurate representation in PFDs are discussed, emphasizing the need for clarity and correct usage in industrial diagrams.

Takeaways

- 😀 Vessels in process flow diagrams (PFDs) represent accumulation or flash tanks and are denoted by the letter 'V'.

- 😀 Accumulators are used for temporary storage or holding process streams before they are sent to another unit. They are not for long-term storage.

- 😀 Flash tanks are separation units, separating a homogeneous stream into vapor and liquid portions based on boiling point, and are always vertical in design.

- 😀 Accumulators have one stream in and one stream out, while separation units like flash tanks have one stream in and two or more streams out.

- 😀 Vertical accumulators hold large amounts of liquid with a small footprint, and are used for vapor-liquid mixtures or venting vapors.

- 😀 Horizontal accumulators are used for smaller volumes, like holding and draining reflux streams from distillation columns.

- 😀 Flash tanks, as single-stage distillation columns, are always vertical and separate components based on boiling points.

- 😀 The default symbols for flash tanks and vapor-liquid separators are commonly used in simulation software like CHEMCAD and Aspen.

- 😀 Valves in PFDs, often depicted with a bow-tie symbol, represent control mechanisms for depressurizing liquid, gas, or vapor streams.

- 😀 There are four common types of valves in chemical processes: ball, gate, globe, and butterfly valves. They each have different functions for controlling flow.

- 😀 Storage tanks, denoted by the abbreviation 'TK', are used for storing raw materials, starting materials, or products, typically holding no more than one month’s worth of material.

Q & A

What is the primary difference between vessels and storage tanks in process flow diagrams?

-Vessels represent process units that have a process stream flowing through them and are not used for long-term storage. They are used for temporary storage or separation processes. Storage tanks, on the other hand, are used for holding raw materials, starting materials, or products for long-term storage and usually have no process stream flowing through them.

What is the purpose of an accumulator in a process flow diagram?

-An accumulator, also known as an accumulation tank or surge tank, temporarily holds a volume of a process stream before it's sent to another unit. It can also handle overflow or temporary volume surges.

How do flash tanks work, and what makes them different from accumulators?

-Flash tanks are separation units that separate a homogeneous stream into vapor and liquid portions based on boiling point. They are similar to single-stage distillation columns but without a reboiler or condenser. Accumulators, in contrast, are used for short-term storage and don't involve separating components.

Why are flash tanks always represented vertically in process flow diagrams?

-Flash tanks are always vertical because they are essentially single-stage distillation columns, and distillation typically requires a vertical tower to separate components effectively.

What are the main characteristics of vertical and horizontal accumulators?

-Vertical accumulators are used for holding large amounts of liquid with a small footprint, often for vapor-liquid mixtures that may require venting or flaring vapors. Horizontal accumulators are used for smaller volumes and are typically used for holding and draining reflux streams in distillation columns.

What is the significance of the valve symbol in process flow diagrams?

-The valve symbol represents devices used to depressurize liquid, gas, or vapor streams in a process. Since there are many types of valves in a chemical process, only the relevant ones for lowering pressure are typically shown, and they usually have a bow-tie shape.

What are the four most common types of valves used in large chemical processes?

-The four most common types of valves are ball valves, gate valves, globe valves, and butterfly valves.

Why should some valves not be used to control flow rate in a process?

-Ball and gate valves are designed only to be fully open or fully closed, and using them to throttle or vary flow rates will damage them. Globe and butterfly valves, on the other hand, are better suited for controlling flow because they are designed for throttling.

What does the symbol for a manually controlled valve represent?

-A manually controlled valve symbol indicates that a person is manually adjusting the flow rate through the valve, typically by opening or closing it. These valves are often globe or butterfly types.

What is the key distinction between an accumulator and a flash tank based on the number of streams?

-An accumulator has one stream coming in and one stream going out, while a flash tank, being a separation unit, has one stream coming in and two or more streams coming out—one for the liquid and one for the vapor.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

How to Read Process Flow Diagrams (PFDs/PFS) - A Complete Tutorial

Fungsi Simbol Flowchart Yang Sering Digunakan

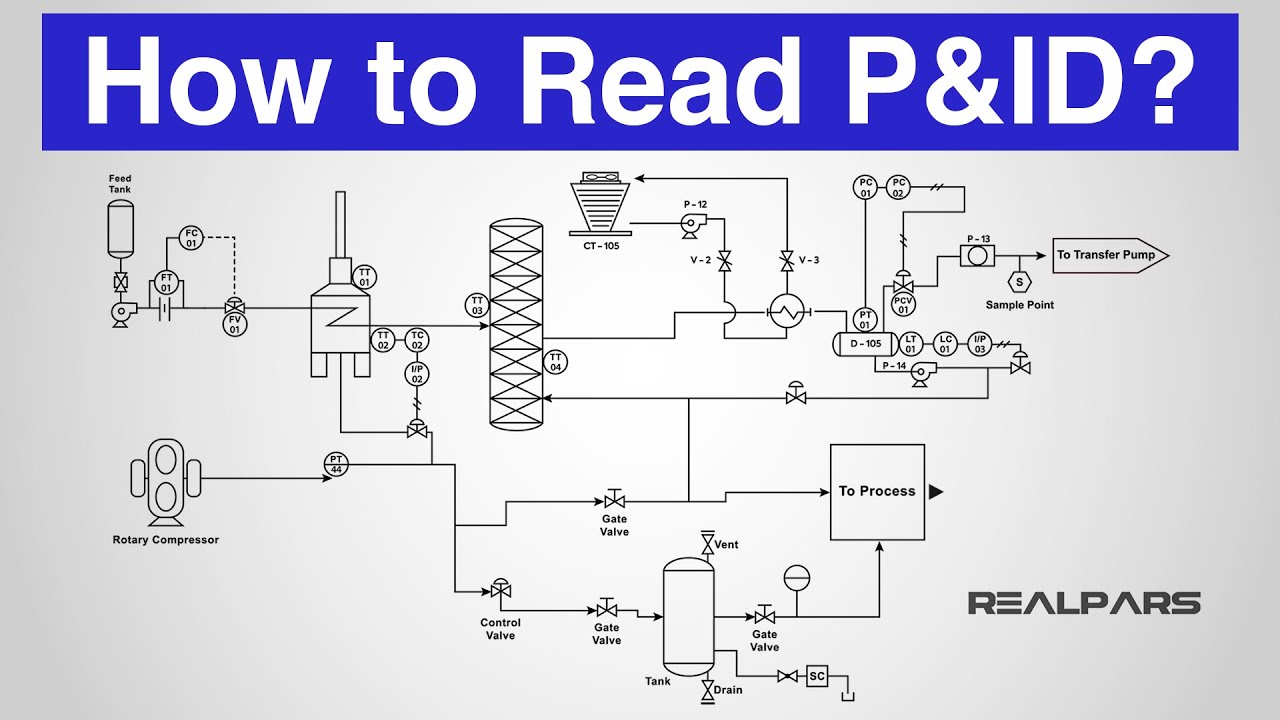

How to Read a P&ID? (Piping & Instrumentation Diagram)

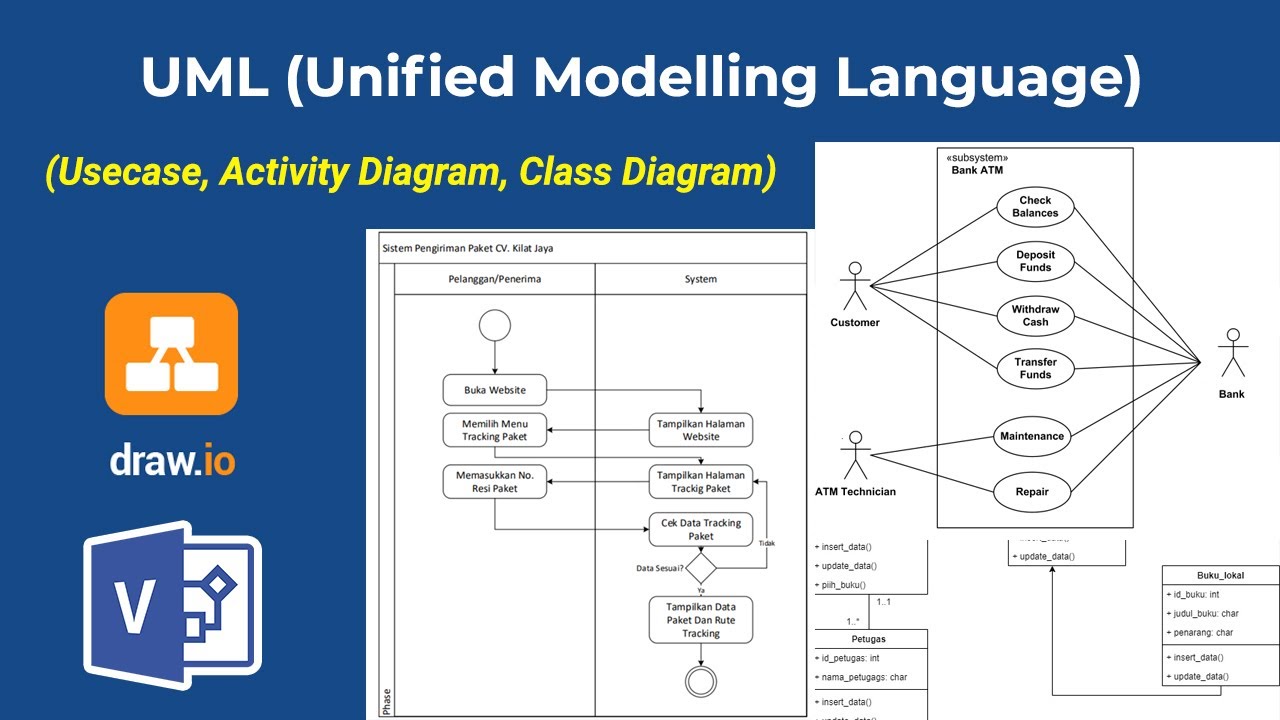

Apa itu UML? Beserta Pengertian dan Contohnya | Belajar UML & Perancangan Sistem

Mudah Memahami Network Diagram (AON & AOA) untuk Proyek Sistem Informasi

ADS #4: Data Flow Diagram & Data Dictionary

5.0 / 5 (0 votes)