Metode Pengendalian Mutu atau Quality Control

Summary

TLDRIn this video, Samsul Arifin explains various methods of quality control in production. He covers four key techniques: direct inspection of products, statistical sampling to ensure quality without checking every item, laboratory testing for physical, microbiological, and chemical analyses, and the importance of traceability systems to track products from production to distribution. The goal is to ensure that all products meet quality standards and that any issues can be quickly traced and addressed. The video emphasizes the importance of accountability and the ability to take action if a product fails to meet safety or quality standards.

Takeaways

- 😀 Quality control (QC) includes multiple methods to ensure product quality.

- 😀 The first method is inspection, which involves directly checking products to ensure they meet standards and specifications.

- 😀 The second method is statistical sampling, which helps ensure quality without inspecting every single product by using representative samples.

- 😀 Testing or analysis, such as physical or chemical analysis in laboratories, is another way to ensure quality for food products.

- 😀 Laboratory testing may include microbiological tests or tests for contaminants like chemicals to ensure products are safe.

- 😀 Traceability is a critical method for tracking the product from production to distribution.

- 😀 A traceability system allows for internal and external tracking to pinpoint issues with a product if problems arise.

- 😀 Traceability helps to identify the origin of raw materials, the production process, and the product's distribution, ensuring accountability.

- 😀 If problems with a product are found, a traceability system enables product recalls and quick action to protect consumers.

- 😀 The goal of implementing a traceability system is to ensure that the company is responsible and can act swiftly in case of quality issues.

- 😀 The video ends with an invitation for further training, consultations, and engagement through their social media channels.

Q & A

What is the first method of quality control mentioned in the script?

-The first method mentioned is inspection, where products are checked directly to ensure they meet the required standards and specifications.

How does statistical sampling contribute to quality control?

-Statistical sampling allows for quality control without inspecting 100% of the products. By using appropriate statistical methods, a sample can represent the entire batch, ensuring the products meet quality standards.

What types of testing or analysis are typically conducted in quality control?

-Testing or analysis can include physical or chemical analyses, microbiological testing, and other tests like measuring pH, moisture content, and contaminants, often carried out in a laboratory.

Why is laboratory testing important in quality control for food products?

-Laboratory testing is crucial to ensure that food products are free from harmful contaminants and meet safety standards. Tests can include microbiological and chemical contamination analysis, ensuring the product is safe for consumers.

What is the purpose of implementing traceability in quality control?

-Traceability ensures that every product can be traced back through its production process. It helps identify the source of any issues, manage product recalls effectively, and maintain accountability in case of quality problems.

How does traceability help with product recalls?

-Traceability allows companies to trace a product's journey from raw materials to final distribution. This helps identify affected products quickly and efficiently, allowing for targeted product recalls if necessary.

What does the implementation of a traceability system ensure for a company?

-It ensures that the company can take responsibility for its products, manage any issues promptly, and recall products if discrepancies or safety issues are found in the market.

What role does the traceability system play in accountability?

-The traceability system provides clear records and evidence of control over production processes, making it easier to hold the company accountable if any problems with the products arise.

What are the benefits of using a statistical sampling method instead of inspecting every product?

-Statistical sampling saves time and resources by testing a representative sample of products, reducing the need for exhaustive inspection of every item while still ensuring quality control.

What is the significance of ensuring product safety through testing and traceability in the food industry?

-Ensuring product safety through testing and traceability helps protect consumers from potential health hazards, enhances consumer confidence, and complies with regulatory standards for food safety.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

FOOD FRAUD ATAU VULNERABILITY ANALYSIS CRITICAL CONTROL POINT (VACCP)

Cara latihan dasar "shooting" bola basket #3 Jump Shot

Inspection and Quality control in Manufacturing. What is quality inspection?

Analisis Bahan Baku Obat

Pengantar Bisnis Sesi 11 Produksi dan Manajemen Operasi

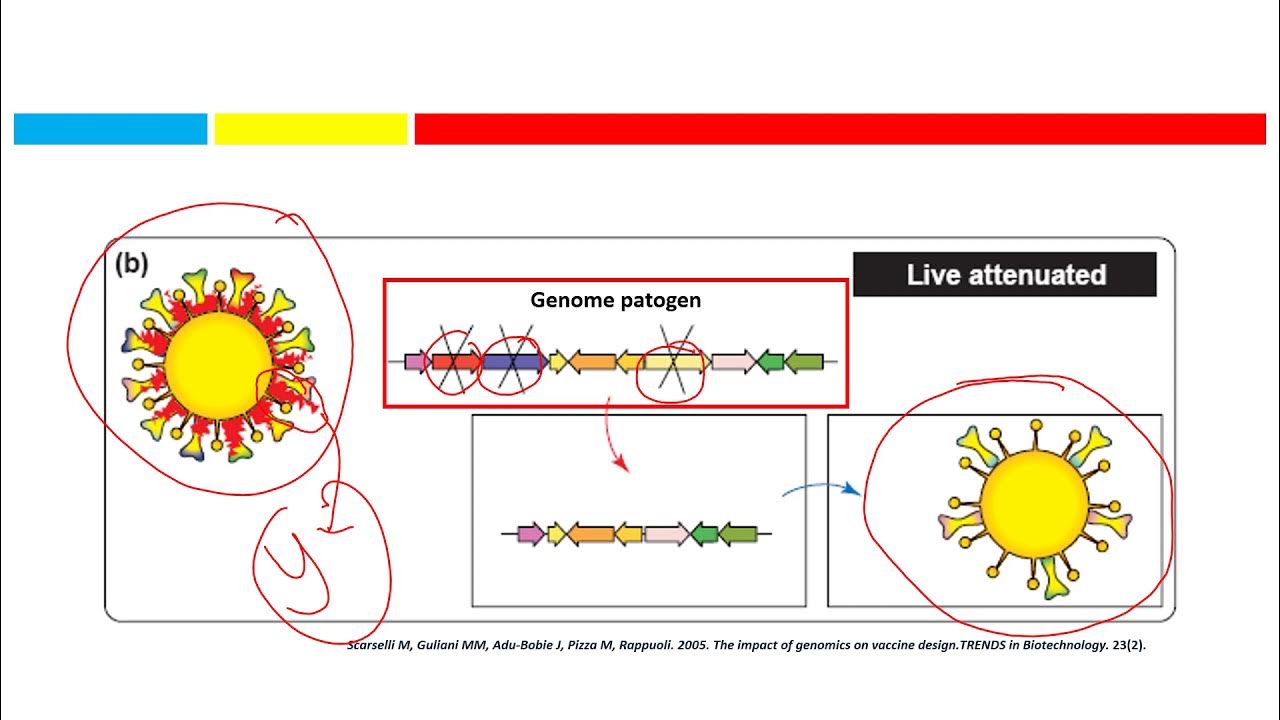

Lecure 11 Teknologi Produksi Vaksin

5.0 / 5 (0 votes)