Analisis Bahan Baku Obat

Summary

TLDRThis lecture focuses on the analysis of raw materials for drug production. It covers the principles of instrumental analysis and its application in the pharmaceutical industry. Key topics include the definition of drugs, regulatory requirements, the role of pharmacopoeias, and the critical importance of quality control in drug production. The lecture also discusses the standardization of raw materials, testing methods, and the flow of receiving, quarantining, and using raw materials in pharmaceutical production. The process of ensuring safety, efficacy, and quality in drug preparation is highlighted, along with the roles of various departments in ensuring compliance with industry standards.

Takeaways

- 😀 Drugs are materials or combinations of materials, including biological products, used to influence or investigate physiological or pathological conditions in order to diagnose, prevent, heal, or improve health, according to law 36/2009 on health.

- 😀 The main goal of raw material analysis for drugs is to ensure that raw materials meet the requirements set in the pharmacopoeia or other recognized standards, such as the US Pharmacopoeia (USP).

- 😀 Pharmaceutical products consist of drugs or raw materials for drugs, also known as active pharmaceutical ingredients (APIs), along with other ingredients necessary for drug formulation.

- 😀 Raw materials for drugs can be single or mixtures of active pharmaceutical ingredients (APIs), and they must meet the standards set by regulatory agencies, including the Indonesian pharmacopoeia and other recognized international standards.

- 😀 The comparative standard for raw materials, such as those from the Indonesian pharmacopoeia, must pass a minimum of three different tests to be officially recognized and used for quality control and testing.

- 😀 Drug raw materials and pharmaceuticals must be safe, effective, and meet quality standards throughout the production process to ensure that the therapeutic effects are maintained.

- 😀 The flow of receiving raw materials involves careful inspection of documents, sampling for quality tests, and ensuring that the raw materials meet the required standards before being used in drug production.

- 😀 Sampling procedures for raw materials should follow specific guidelines to ensure representative testing, such as taking samples from multiple containers when received in bulk, and verifying conformity with certificates of analysis from suppliers.

- 😀 Raw material testing is conducted to ensure compliance with pharmacopoeial standards, and testing can be instrumental or conventional. Re-testing may be required annually or biannually to ensure continuous quality.

- 😀 The quality control section plays a critical role in ensuring that raw materials, packaging materials, and finished products meet the required specifications, with oversight throughout the entire production process from raw material receipt to product release.

- 😀 Quality control involves several stages, including checking the weight and composition of raw materials, monitoring the production process, and ensuring that finished products pass final testing before certification for distribution.

Q & A

What is the primary objective of analyzing raw materials for drugs?

-The primary objective is to ensure that raw materials for drugs meet the quality standards set by pharmacopoeias or other standards, ensuring the safety, efficacy, and therapeutic effectiveness of the final pharmaceutical product.

How does the Indonesian Pharmacopoeia define drugs?

-Drugs are materials or combinations of materials, including biological products, used to influence or investigate physiological systems or pathological conditions for diagnosis, prevention, healing, recovery, health improvement, or contraception in humans.

What is the role of a pharmacopoeia in drug raw material analysis?

-A pharmacopoeia provides the standards and specifications that raw materials must meet. It serves as a reference for quality control, ensuring that raw materials are suitable for pharmaceutical production.

What are the key components of a pharmaceutical product?

-A pharmaceutical product contains one or more drugs (active pharmaceutical ingredients) combined with pharmaceutical excipients or auxiliary materials that aid in the formulation and administration of the drug.

What does CPB stand for, and why is it important in drug manufacturing?

-CPB stands for 'C Good Manufacturing Practices' (GMP), which sets standards for the production of drugs. These standards ensure that pharmaceutical products are produced consistently and meet quality requirements for safety, efficacy, and quality.

What are the different types of standards used for raw materials?

-Raw materials for drugs are compared against different standards such as the Indonesian Pharmacopoeia, USP (United States Pharmacopoeia), BP (British Pharmacopoeia), and JP (Japanese Pharmacopoeia), among others. These standards help determine the quality of raw materials.

What is the significance of the Certificate of Analysis for raw materials?

-The Certificate of Analysis is crucial for ensuring that raw materials meet the required quality standards and are suitable for use in pharmaceutical manufacturing. It verifies that the raw material has passed all necessary tests and complies with specifications.

How are raw materials sampled for quality testing?

-Raw materials are sampled according to a specified procedure. The number of samples taken is determined by the square root of the total number of containers. Each container is sampled to ensure consistency and quality in the raw materials.

What happens if raw materials fail to meet the required standards?

-If raw materials do not meet the specified standards, they are rejected and returned to the supplier. The rejection is based on discrepancies in the Certificate of Analysis or failure to meet quality requirements during testing.

What is the role of the quality control (QC) section in drug production?

-The QC section is responsible for ensuring that raw materials, packaging materials, the production process, and finished products meet the specified quality criteria. They perform tests and validations throughout the manufacturing process to ensure compliance with regulatory standards.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Manajemen Produksi Ep.04 Manajemen Bahan Baku

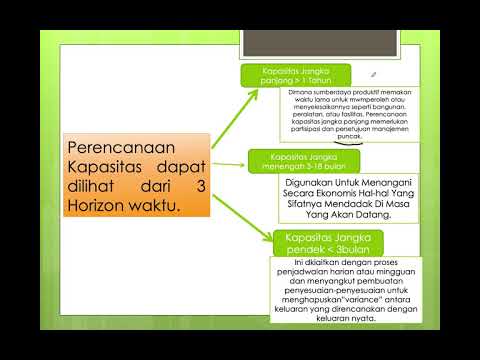

MPO KAPASITAS PABRIK

Manajemen Produksi Ep.05 Manajemen Persediaan

BAGAIMANA SIH INDUSTRI FARMASI MENENTUKAN HARGA SEBUTIR OBAT ? || Belajar Manajemen Farmasi Industri

Business Sectors Explained 📌

Identifikasi dan Pengendalian Bahaya Mesin dalam Proses Produksi Ban Kendaraan

5.0 / 5 (0 votes)