What Is A VFD? (Variable Frequency Drive) HVAC VFD BASICS

Summary

TLDRIn this video, the host explains the concept of Variable Frequency Drives (VFDs), also known as variable speed drives, adjustable frequency drives, and inverters. VFDs are used to control the speed of AC motors by varying the frequency and voltage supplied, offering energy savings, improved process control, and extended equipment life. They are widely used in HVAC systems, manufacturing, and processing plants. Key benefits include energy cost savings, reduced motor stress, and a decrease in greenhouse gas emissions. This video provides a beginner-friendly overview, with further details on VFD operations to be covered in the next video.

Takeaways

- 😀 VFD stands for Variable Frequency Drive, a type of motor controller that adjusts the speed of electric motors by varying frequency and voltage.

- 😀 Other names for VFD include Variable Speed Drive (VSD), Adjustable Speed Drive (ASD), AC Drive, Micro Drive, and Inverter.

- 😀 VFDs are commonly used to control the speed of AC motors, including in systems like conveyors, blowers, pumps, and machine tools.

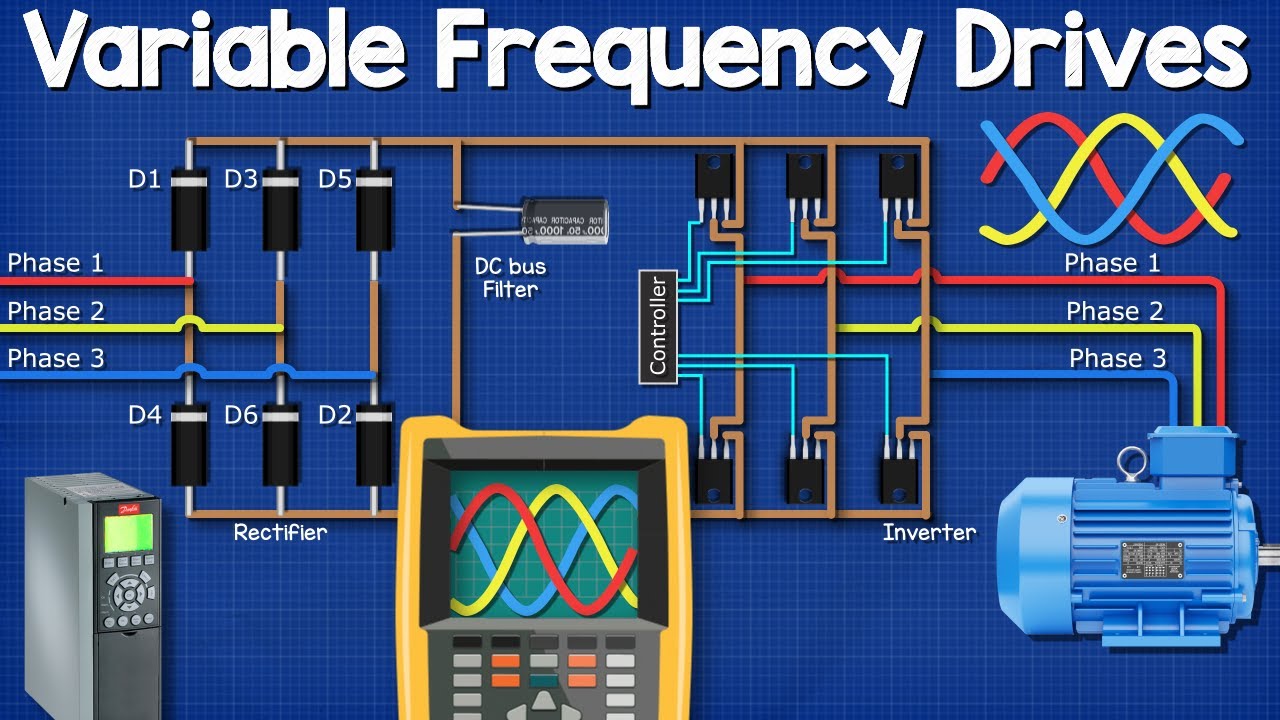

- 😀 A VFD works by rectifying incoming AC current into DC, then using pulse-width modulation to recreate AC current, controlling motor speed.

- 😀 VFDs offer significant energy cost savings by reducing the motor speed and energy consumption compared to traditional methods like belts or gearboxes.

- 😀 One of the key benefits of VFDs is their ability to provide soft-start functionality, reducing inrush current and mechanical stress during motor startup.

- 😀 By controlling motor speed, VFDs contribute to energy efficiency, which can reduce greenhouse gas emissions by approximately 40%.

- 😀 VFDs can help improve process control, enhance motor reliability, and reduce wear and tear on equipment.

- 😀 Energy savings from VFDs can be substantial, as motors consume much less energy at half their maximum speed compared to running at full speed.

- 😀 This video is targeted at beginners, explaining the basics of VFDs, with future content planned to cover more detailed operations of VFDs.

Q & A

What does VFD stand for?

-VFD stands for Variable Frequency Drive, which is a type of motor controller used to regulate the speed of an electric motor by adjusting the frequency and voltage supplied to it.

What are some alternative names for VFDs?

-Other names for VFDs include Variable Speed Drive (VSD), Adjustable Speed Drive (ASD), Adjustable Frequency Drive (AFD), AC Drive, Micro Drive, and Inverter.

How does a VFD work to control motor speed?

-A VFD works by converting incoming AC power to DC through a rectifier and then using Pulse Width Modulation (PWM) to recreate an AC output that controls the frequency and voltage, thus adjusting the speed of the motor.

What types of motors can be controlled by a VFD?

-VFDs are commonly used to control standard AC motors, such as AC induction motors or synchronous motors.

What are some typical applications for VFDs?

-VFDs are widely used in applications that require variable speed control, such as conveyor systems, blower speeds, pump speeds, machine tools, and HVAC systems.

What are the main benefits of using a VFD?

-The main benefits of using a VFD include energy savings, soft-start capability, reduced mechanical stress on motors, improved process control, and extended motor life.

How do VFDs contribute to energy savings?

-VFDs save energy by adjusting the speed of motors based on demand. This is more efficient than using mechanical methods like belts or gearboxes to change speed, as the motor only consumes the energy it needs.

What is the environmental impact of using VFDs?

-VFDs can significantly reduce energy consumption, which in turn helps reduce greenhouse gas emissions. It's estimated that energy efficiency improvements from VFDs can cut emissions by up to 40% globally.

What is the significance of VFDs having soft-start capability?

-The soft-start capability of VFDs helps reduce the inrush current during motor startup, preventing mechanical stress on the motor and enhancing its overall reliability and longevity.

How does running a motor at half speed with a VFD affect its energy consumption?

-When a motor operates at half its maximum speed with a VFD, it consumes significantly less energy compared to running at full speed. This is because the motor only uses the energy required for the lower speed.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahora5.0 / 5 (0 votes)