Drive Basics

Summary

TLDRThis video from Yaskawa America Incorporated delves into the intricacies of Variable Frequency Drives (VFDs), exploring their remarkable capabilities in energy savings and machine maintenance reduction. Host Steve Koehler guides viewers through the basics of VFDs, discussing their applications in industrial and commercial settings, starting methods, and the benefits of variable speed control. The presentation covers the inner workings of VFDs, including their components and control methods, and concludes with a practical look at drive enclosures and a Q&A session. Yaskawa emphasizes its commitment to product excellence and customer support.

Takeaways

- 😀 Variable Frequency Drives (VFDs) are crucial for energy saving, reducing machine maintenance, and providing precise control over processes powered by three-phase AC motors.

- 🛠️ VFDs, also known as Adjustable Speed Drives, Adjustable Frequency Drives, AC Drives, and Inverters, are used to control and monitor electric motors in various applications.

- 🏭 Industrial applications like conveyors, cranes, hoists, and presses benefit from precise speed control, which VFDs provide by replacing complex mechanical systems.

- 💧 Commercial applications such as fans and pumps use VFDs to regulate flow and pressure, potentially leading to energy savings that can pay for the VFD system itself.

- 🔋 VFDs offer full torque capability over a wide range of frequencies, allowing for the use of standard motors in more applications and providing precise control over acceleration and deceleration.

- 🛡️ Built-in motor protection in VFDs eliminates the need for external protection, and in variable torque applications, affinity laws can lead to significant energy savings.

- 🔧 VFDs can generate torque at zero speed for holding or locking the rotor, a feature that was previously limited to servos and mechanical brakes.

- 🌐 Remote Monitor Control with VFDs allows for system monitoring and control from anywhere with an internet connection, enhancing operational flexibility.

- 🏗️ The main components of a VFD include the Control Board, which acts as the brain of the drive, managing user inputs and system tasks, and the Power board, which handles high and low voltage areas.

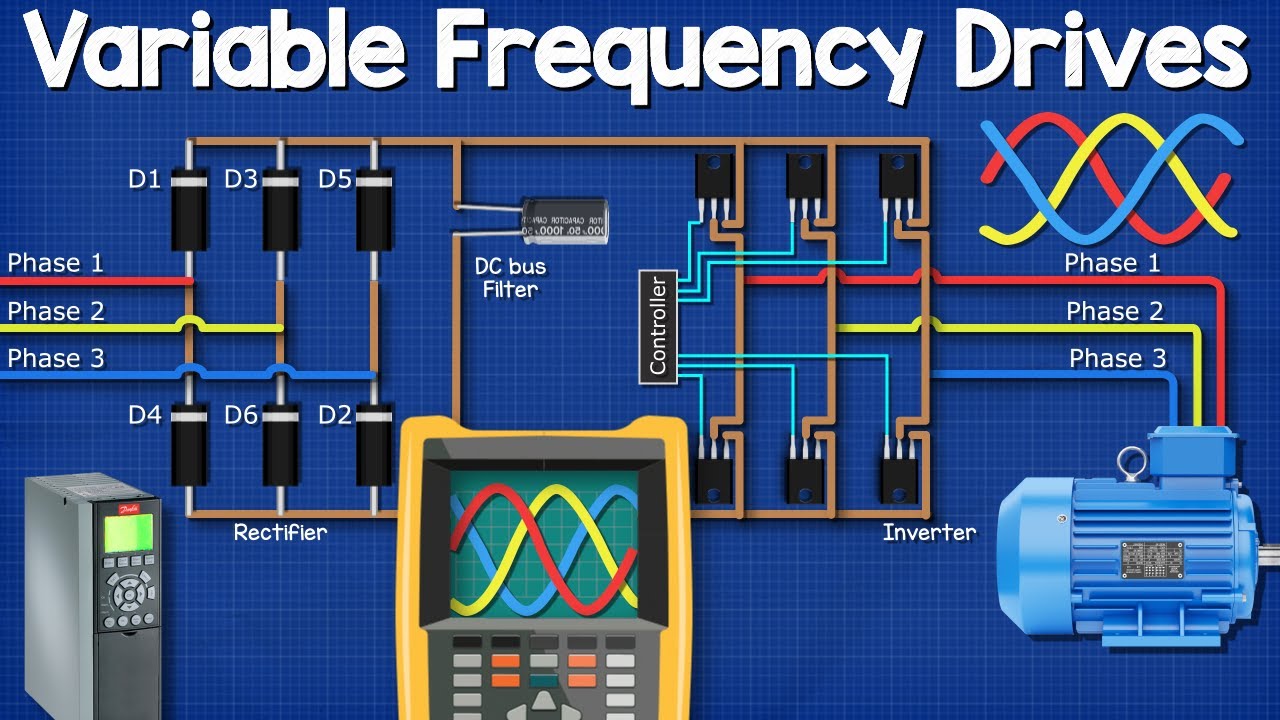

- ⚙️ The Inverter Section of a VFD uses IGBTs to produce a simulated three-phase AC waveform for the motor, with Pulse Width Modulation (PWM) controlling the IGBTs to build the waveform.

Q & A

What is a Variable Frequency Drive (VFD) and what are its common alternative names?

-A Variable Frequency Drive, or VFD, is a device that controls and monitors electric motors. It is also known as Adjustable Speed Drives, Adjustable Frequency Drives, AC Drives, and Inverters.

How do VFDs help in energy savings and reducing maintenance?

-VFDs help in energy savings by allowing precise control over motor speed and torque, which can reduce the amount of energy used. They also reduce maintenance as they can eliminate mechanical speed, flow, and pressure control systems that may be difficult to regulate and could be potential failure points.

What are some industrial applications that can benefit from using a VFD?

-Industrial applications such as Conveyors, Cranes and Hoists, Presses, Winders and Unwinders, and High-Speed Machining Applications can benefit from using a VFD due to their need for precise control over motor speed.

How do commercial applications like fans and pumps utilize VFDs for flow and pressure control?

-Commercial applications use VFDs to adjust speed and torque according to system demands, removing the need for mechanical control systems like inlet guide vanes, bypass dampers, and discharge valves, which can be difficult to regulate.

What are the major capabilities that a VFD provides for motor control?

-VFDs provide capabilities such as altering the speed-torque curve, matching motor speed to load requirements, providing full torque capability over a wide range of frequencies, and allowing for customized acceleration and deceleration times.

What is the purpose of Metal Oxide Varistors (MOVs) in a VFD?

-MOVs are used to protect the VFD from incoming voltage transients or spikes, such as those associated with relay and contactor operations, by allowing these spikes to bleed off safely.

How does a VFD affect the starting process of a motor and what are the benefits?

-A VFD allows for a soft start by gradually increasing the frequency and voltage to the motor, which reduces the inrush current and provides a smoother start, limiting the stress on the motor and connected equipment.

What is the role of the Control Board in a VFD and how does it function?

-The Control Board acts as the brain of the VFD, receiving information from the user and other drive components, and relaying tasks to appropriate areas. It also allows for programming of various parameters such as overloads, acceleration and deceleration rates, and speed limits.

Can you explain the function of the Inverter Section in a VFD and how it produces a three-phase AC waveform?

-The Inverter Section uses Insulated Gate Bipolar Transistors (IGBTs) to produce a simulated three-phase AC waveform for the motor. It does this by rapidly switching the IGBTs on and off in a Pulse Width Modulation (PWM) scheme to build a waveform that resembles a sine wave.

What is the significance of the Carrier Frequency in the operation of a VFD?

-The Carrier Frequency determines the rate at which the IGBTs switch in the VFD. A higher Carrier Frequency results in a cleaner, more sinusoidal current waveform, which can reduce motor noise but also increases heat generation within the drive.

How does a VFD enclosure's NEMA rating affect its suitability for different environments?

-The NEMA rating of a VFD enclosure indicates its level of protection against environmental factors. For example, NEMA 1 is for indoor use with basic protection, NEMA 4X is for both indoor and outdoor use with protection against water and corrosion, and NEMA 3R is designed for outdoor use with protection against rain and sleet.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)