What is the Difference between VFD and Soft Starter?

Summary

TLDRThis video compares Soft Starters and Variable Frequency Drives (VFDs), explaining how both devices control the starting and stopping of motors in industrial applications. A Soft Starter limits inrush current and ramps motor speed up or down, while a VFD can also control motor speed in addition to its ramping functionality. The choice between a Soft Starter and VFD depends on the application’s needs, with Soft Starters being cheaper and smaller but limited to controlling start/stop actions. Real-world examples, such as wastewater pumps and cooling fans, illustrate when to use each device. Finally, the video emphasizes how a VFD can replace a Soft Starter and vice versa depending on future requirements.

Takeaways

- 😀 Soft Starters help protect motors by controlling the large inrush of current during startup, preventing motor damage.

- 😀 A Variable Frequency Drive (VFD) allows for motor speed control in addition to starting and stopping the motor.

- 😀 The main components of a Soft Starter include six Thyristors (Silicon Controlled Rectifiers) that control the current flow to the motor.

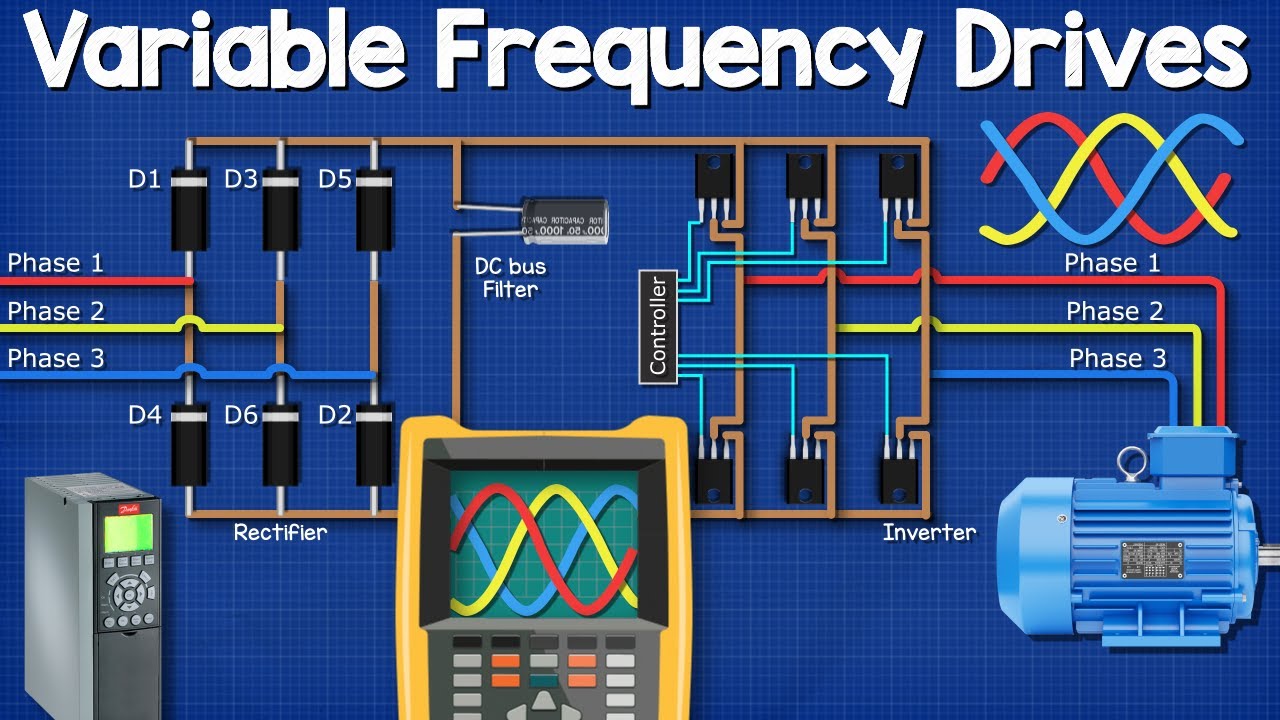

- 😀 The VFD consists of a Rectifier (converts AC to DC), a Filter (smoothens the DC), and an Inverter (converts DC back to variable frequency for speed control).

- 😀 Soft Starters are ideal for applications where speed control is unnecessary, and only smooth motor startups and shutdowns are required.

- 😀 VFDs are more expensive than Soft Starters but provide added benefits like variable motor speed control, making them suitable for more complex applications.

- 😀 The decision between using a Soft Starter or VFD depends on the level of control required for the motor's operation.

- 😀 In applications like wastewater pumps with constant flow, a Soft Starter is sufficient since the pump speed does not need to vary.

- 😀 Cooling fans, which require variable speed based on temperature, are better suited for VFDs due to the need for speed adjustment.

- 😀 Soft Starters are smaller and more cost-effective than VFDs, making them an attractive choice when size and budget are critical.

- 😀 A Soft Starter can be replaced with a VFD if speed control becomes necessary, and vice versa, offering flexibility depending on evolving needs.

Q & A

What is the main function of a Soft Starter?

-A Soft Starter is used to manage the inrush current during motor startup, gradually ramping up the motor to prevent damage due to high starting currents. It doesn't control the motor speed once it's running.

How does a Soft Starter work internally?

-A Soft Starter typically uses six Thyristors or Silicon Controlled Rectifiers (SCRs) arranged in an antiparallel configuration. These SCRs control the flow of current to the motor by applying internal pulses to their gates, allowing current to flow in a controlled manner to smoothly ramp up the motor's speed.

What are the key components of a Variable Frequency Drive (VFD)?

-A VFD consists of three main components: a Rectifier (which converts AC to DC), a Filter (which smooths out the DC voltage), and an Inverter (which converts the DC back into AC at a controlled frequency to control the motor's speed).

What is the primary difference between a VFD and a Soft Starter?

-The primary difference is that a VFD not only controls the motor's startup but also varies the motor's speed by adjusting the frequency of the current. In contrast, a Soft Starter only controls the motor's startup and shutdown, without speed control.

When would a Soft Starter be a better choice than a VFD?

-A Soft Starter is better when the application involves handling a large inrush current during startup but doesn't require speed control. It's ideal for applications like wastewater pumps where the motor runs at a constant speed.

When is a VFD necessary instead of a Soft Starter?

-A VFD is necessary when speed control is required for the motor. This is typically the case in applications like cooling fans, where the motor speed needs to vary depending on environmental conditions, such as temperature changes.

How does a VFD control the motor speed?

-A VFD controls the motor speed by adjusting the frequency of the AC voltage supplied to the motor. The Inverter component of the VFD changes the DC voltage into an AC signal at a specific frequency, which in turn determines the motor's speed.

What happens to the motor when a Soft Starter is used?

-When a Soft Starter is used, the motor experiences a gradual ramp-up in voltage, preventing a sudden surge of current that could damage the motor. Once the motor reaches its preset maximum speed, it continues running at that speed until stopped, at which point the Soft Starter will ramp down the motor.

Can a Soft Starter be replaced by a VFD, and vice versa?

-Yes, a Soft Starter can be replaced by a VFD if speed control becomes necessary. Similarly, if speed control is not needed in a VFD application, a Soft Starter can replace the VFD.

What role does price play in the decision between a VFD and a Soft Starter?

-Price is a significant factor, as Soft Starters tend to be less expensive than VFDs due to their simpler control functions. If speed control is not required, opting for a Soft Starter can offer a more cost-effective solution.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Drive Basics

What Is A VFD? (Variable Frequency Drive) HVAC VFD BASICS

Variable Frequency Drives Explained - VFD Basics IGBT inverter

How alternating current motors work?

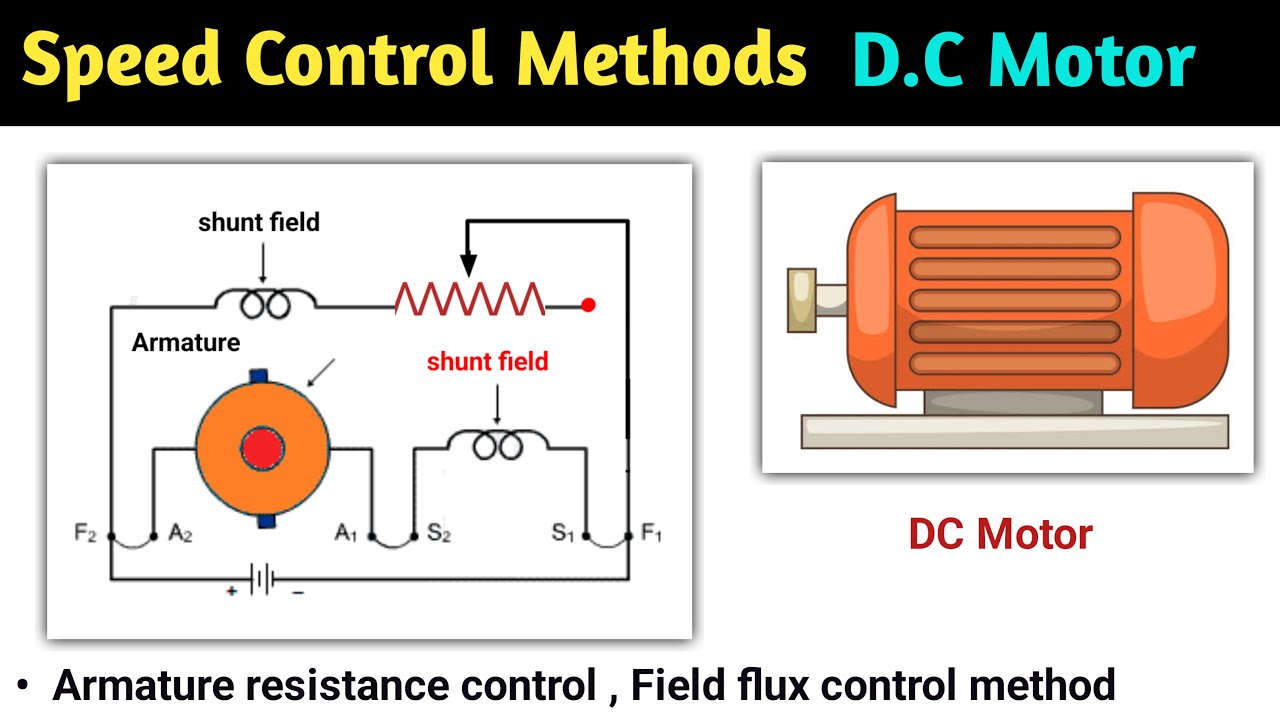

speed control of dc motor | speed control of dc shunt motor | dc motor speed control | series motor

James Allen, M.D. & Preventive Maintenance Plus

5.0 / 5 (0 votes)