Linking Parameter Toolpath Mastercam Programming

Summary

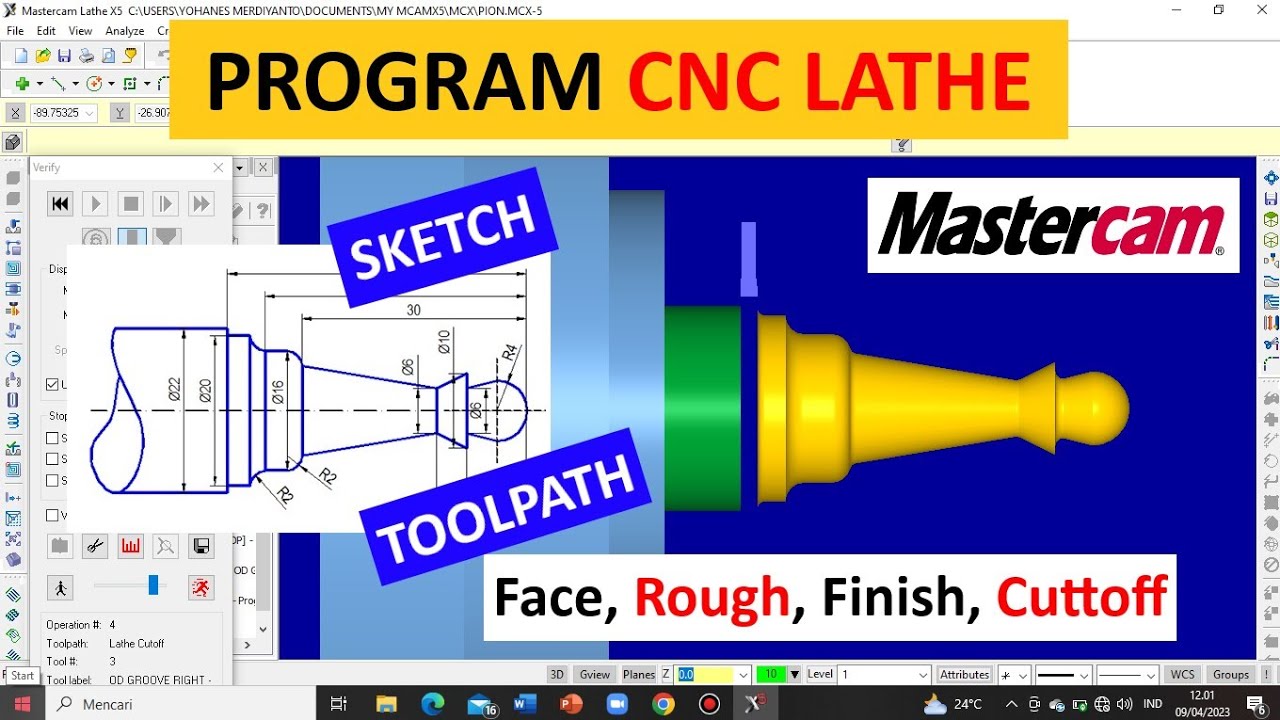

TLDRThis video script offers an in-depth tutorial on using linking parameters in Mastercam's toolpath creation. It explains the concept of linking parameters, showcasing how to create a program with a 100x100 workpiece, offset, and trim operations. The tutorial delves into setting up toolpaths, selecting tools, and adjusting parameters like clearance, retract, and feed rates. It also covers the significance of 'Fit plan' and 'Top of stock' settings, providing practical examples and simulations to clarify the impact of these parameters on tool movement and machining accuracy.

Takeaways

- 🔧 The script discusses the concept of 'linking parameters' in Mastercam's toolpath creation, which are crucial for defining how the tool interacts with the workpiece.

- ✅ 'Linking parameter' is used to set the behavior of the tool as it moves and cuts the material, including parameters like 'retract', 'feed', and 'clearance'.

- 📏 The 'offset' function is used to create a toolpath that is a certain distance away from the original workpiece dimensions, which can be useful for creating a relief or avoiding tool collisions.

- 🔩 'Toolpad' settings are essential for visualizing and adjusting the toolpath in relation to the workpiece, including the stock setup and display.

- 🎛️ 'Stock setup' involves defining the size and position of the workpiece, which is critical for accurate toolpath generation.

- 🛠️ The 'Create new tool' option allows users to specify tool characteristics such as type and size, which affects how the toolpath is executed.

- 🔼 'Retract' distance is the vertical distance the tool moves away from the workpiece before transitioning to a different operation, ensuring safety and precision.

- 🔄 'Feed' rate is the speed at which the tool moves along the workpiece, with 'Fit plan' defining the point where the tool begins cutting at the set feed rate.

- 🔎 'Clearance' height is the distance the tool maintains above the workpiece when moving between operations, preventing collisions and ensuring smooth transitions.

- 📉 'Depth of cut' refers to how far the tool penetrates into the workpiece, with settings adjusted based on the material and tool capabilities.

Q & A

What is a linking parameter in Mastercam toolpath creation?

-A linking parameter in Mastercam refers to the settings that control the movement and behavior of the tool between different operations or steps in a toolpath. It includes settings like clearance, retract, and feed rates.

How do you create a simple toolpath in Mastercam for a 100x100mm workpiece?

-To create a simple toolpath, you would define the workpiece size, offset it, trim the excess material, and then extrude the toolpath downwards to the desired depth, setting parameters like depth, feed rate, and tool type accordingly.

What is the purpose of the 'clearance' setting in the linking parameters?

-The 'clearance' setting in linking parameters is the distance the tool travels above the workpiece surface before starting the cutting action. It ensures the tool does not collide with the workpiece during rapid movements.

What does the 'retract' distance signify in Mastercam's linking parameters?

-The 'retract' distance is the distance the tool moves away from the workpiece after completing a cut or before changing direction. It's used to ensure the tool clears the workpiece without causing damage.

How do you set up the stock in Mastercam for a workpiece?

-To set up the stock in Mastercam, you would go to the stock setup, select the bounding box option, and define the size and thickness of the workpiece to match the physical dimensions.

What is the significance of the 'Fit plan' setting in the linking parameters?

-The 'Fit plan' setting determines the point at which the tool begins the cutting action with a feed rate. It's used to transition from rapid movement to the cutting feed rate at a specified distance from the starting cut.

What is the 'top of stock' setting in Mastercam and how is it used?

-The 'top of stock' setting represents the upper limit of the workpiece surface. It's used to define the starting Z position for the tool, ensuring the tool does not go below the workpiece surface.

How do you create a new tool in Mastercam for contouring?

-To create a new tool, you would right-click in the tool list, select 'Create new tool', choose the tool type such as 'flat', and define the tool's diameter and other specifications before finalizing the creation.

What is the purpose of the 'depth' setting in the cut parameters?

-The 'depth' setting in the cut parameters defines the total depth the tool will cut into the workpiece. It's crucial for determining the depth of each cut layer during the machining process.

How do you simulate the toolpath in Mastercam to visualize the machining process?

-To simulate the toolpath, you would use the simulation feature in Mastercam, which allows you to visualize the tool movement and cutting action, ensuring the toolpath is correct before actual machining.

What does the 'lead in' and 'lead out' setting control in Mastercam?

-The 'lead in' and 'lead out' settings control the approach and exit paths of the tool during the cutting process. They ensure smooth transitions into and out of the cut, reducing the risk of tool breakage or workpiece damage.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Cara membuat program Pocket pada mastercam 2017 - Rectangular pocket for CNC Machine 2D process

TUTORIAL MASTERCAM X5 MEMBUAT PION || CNC Turning (Lathe) || Simpel & Mudah dipahami !!

#14 Startup Code Part-2: Replacing the vector-table, embedded software build process

MACBETH'S FEAR STUDENT GRADE 9 ESSAY (5 HACK to ANY ESSAY)

Create your Airbnb Listing like this

How Control the Camera, Angle and Distance on an AI Art Scene in MidJourney?

5.0 / 5 (0 votes)