Understanding Production Volume & Plant Layout: Job, Batch, and Mass Production Explained!

Summary

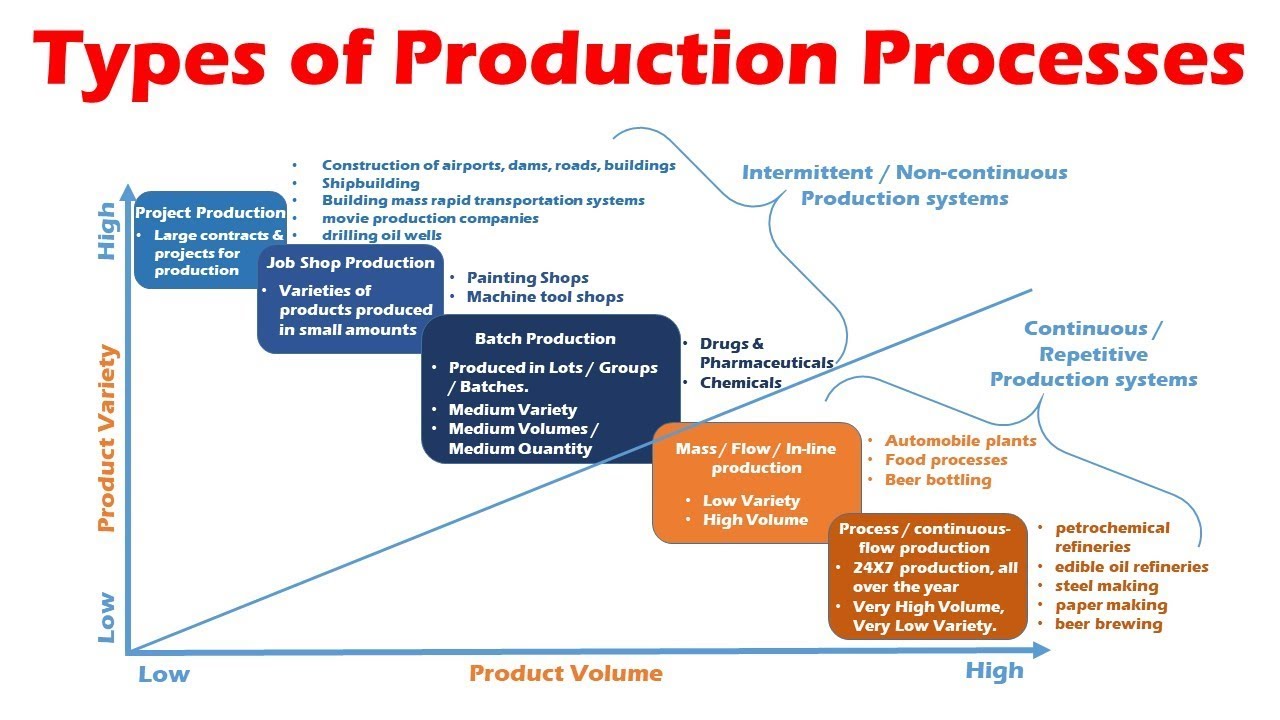

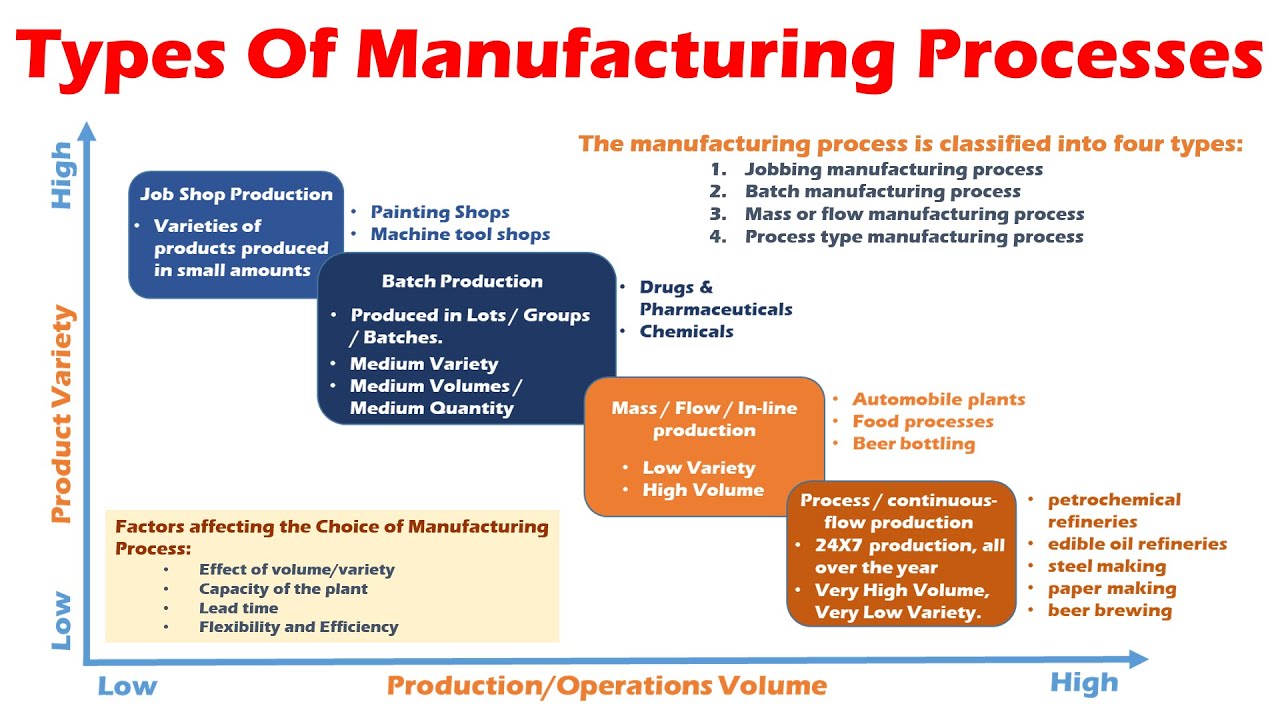

TLDRThis video explores how production volume influences plant layout in manufacturing, highlighting three key production types: job, batch, and mass production. Job production focuses on low volume and high variety, employing flexible equipment and workflows. Batch production features medium volume and variety, using semi-specialized equipment and semi-automated material handling. In contrast, mass production emphasizes high volume and low variety, relying on highly specialized equipment and fully automated systems. Understanding these dynamics is crucial for designing efficient manufacturing facilities that meet specific business needs.

Takeaways

- 😀 Production volume significantly influences plant layout and efficiency in manufacturing.

- 🔄 Job production involves low volume and high variety, typically using flexible machines like CNC machines.

- 🔧 In job production, the workforce is multi-skilled and adaptable to handle various products.

- 📦 Batch production is characterized by medium volume and medium variety, employing semi-specialized equipment.

- 🔄 In batch production, material handling is often semi-automated with systems like automated storage and retrieval.

- ➡️ Mass production focuses on high volume and low variety, utilizing highly specialized equipment like assembly lines.

- 🤖 In mass production, material handling is fully automated, often using robotic systems.

- 🛠️ The workflow design in job production is often flexible (U-shaped or circular) to accommodate different products.

- 🔍 Quality control varies by production type: inspection and testing for job production, process control for mass production.

- 🏭 Understanding the relationship between production volume and layout design is essential for efficient manufacturing.

Q & A

What is the relationship between production volume and plant layout?

-Production volume significantly influences plant layout, as different production types require different equipment, workflows, and labor forces to maximize efficiency.

What characterizes job production?

-Job production is characterized by low volume and high variety, such as producing 100 units a month with 10 different products, requiring flexible equipment and workflows.

What types of machines are commonly used in job production?

-Flexible general-purpose machines like CNC machines and Universal testing machines are commonly used in job production, along with manual material handling systems like forklifts.

How is the labor force structured in job production?

-In job production, the labor force is multi-skilled and adaptable, capable of handling various products and tasks.

What is batch production and how does it differ from job production?

-Batch production involves medium volume and medium variety, typically around 1,000 units a month across five different products, and uses semi-specialized equipment.

What equipment is typically used in batch production?

-Batch production often employs semi-specialized equipment like batch processing machines and robotic welders.

What does the workflow design look like in batch production?

-The workflow design in batch production is often linear or L-shaped, providing some flexibility in handling different products.

What are the characteristics of mass production?

-Mass production is defined by high volume and low variety, such as producing 10,000 units a month of one or two products, with highly specialized equipment and fully automated material handling.

What kind of quality control measures are utilized in mass production?

-Quality control in mass production focuses on process control and automation to ensure consistent product quality.

How can understanding production volume and plant layout benefit manufacturers?

-Understanding the relationship between production volume and plant layout allows manufacturers to design efficient facilities that meet specific needs and support their business objectives.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Process Strategies

Exploring Production Methods: Job, Batch, and Flow Production Explained | ThinkIGCSE.com

Types of Production Systems (Process, Mass, Flow, Batch, Job Shop & Project Production Systems)

Types Of Manufacturing Processes (Job Shop, Batch, Mass, Flow, Process Type Manufacturing Processes)

Job, batch, flow and mass customization methods - Business Management - Teacher RK

Lec 20: Plant Layout: Cellular and Process Layout

5.0 / 5 (0 votes)