Part Modeling - Create a Shell Feature

Summary

TLDRThis video provides a tutorial on preparing for the Autodesk Fusion 360 Certified User Exam by focusing on creating a shell feature in Fusion 360. The instructor demonstrates how to create and shell a solid object, explaining key operations such as removing faces and adjusting wall thicknesses. The video covers practical applications like 3D printing and how to use the section analysis tool to inspect the shell. The tutorial concludes by emphasizing the importance of mastering these tasks for exam success and encourages viewers to continue studying and practicing.

Takeaways

- 🔧 The video focuses on the Autodesk Fusion 360 Certified User Exam, covering specific exam objectives.

- 📐 The feature discussed in this video is creating a shell feature in Fusion 360, a common part modeling technique.

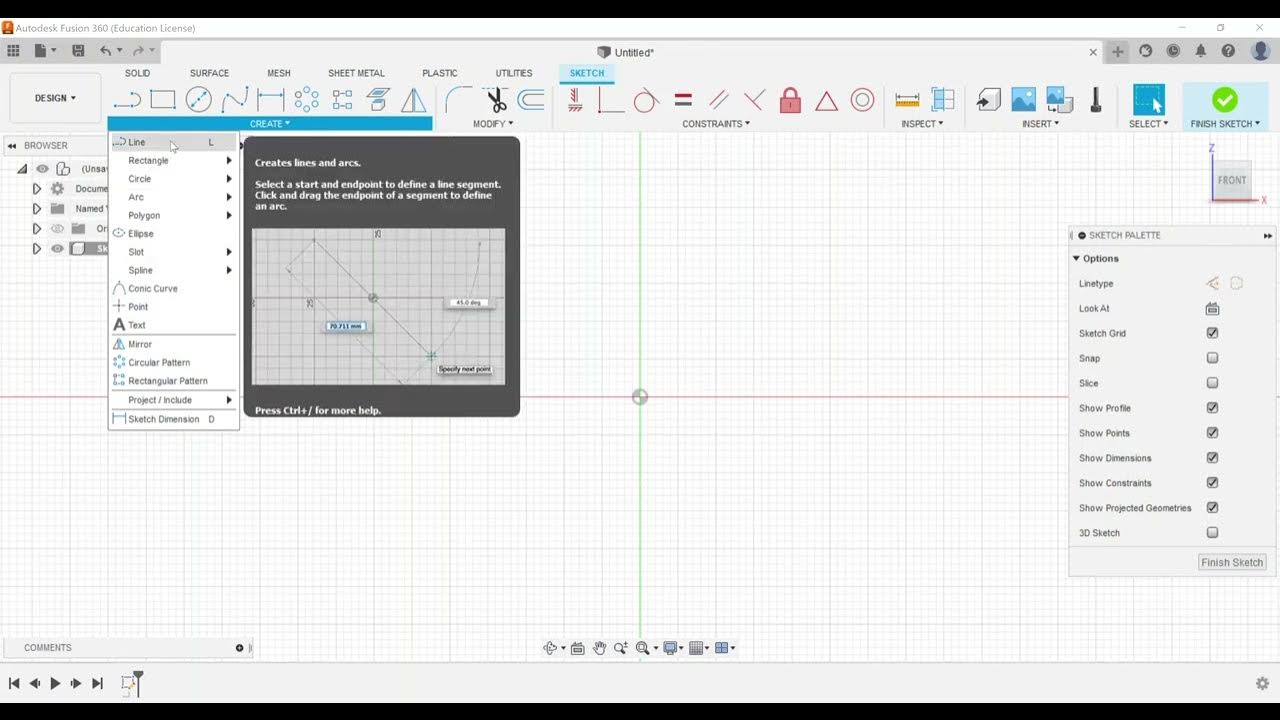

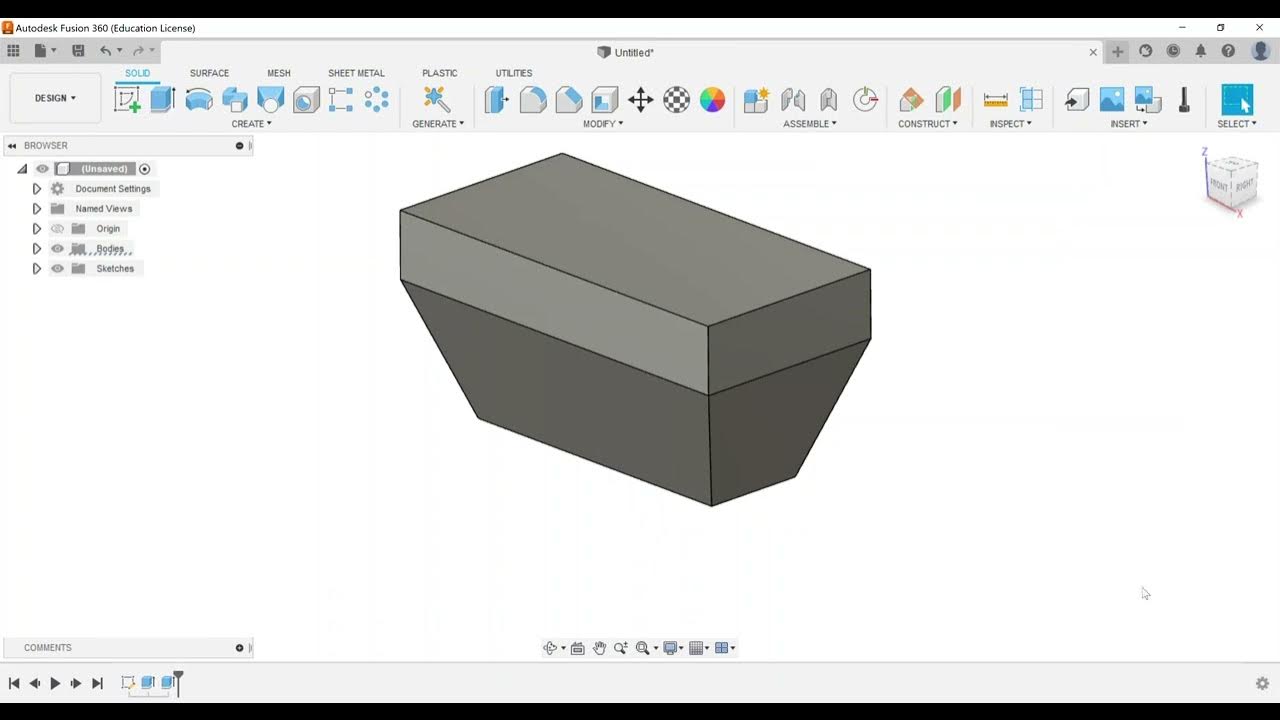

- 🚀 To create a shell, the user begins by creating a sketch of a cylinder, which is extruded to a desired height (e.g., 4 inches).

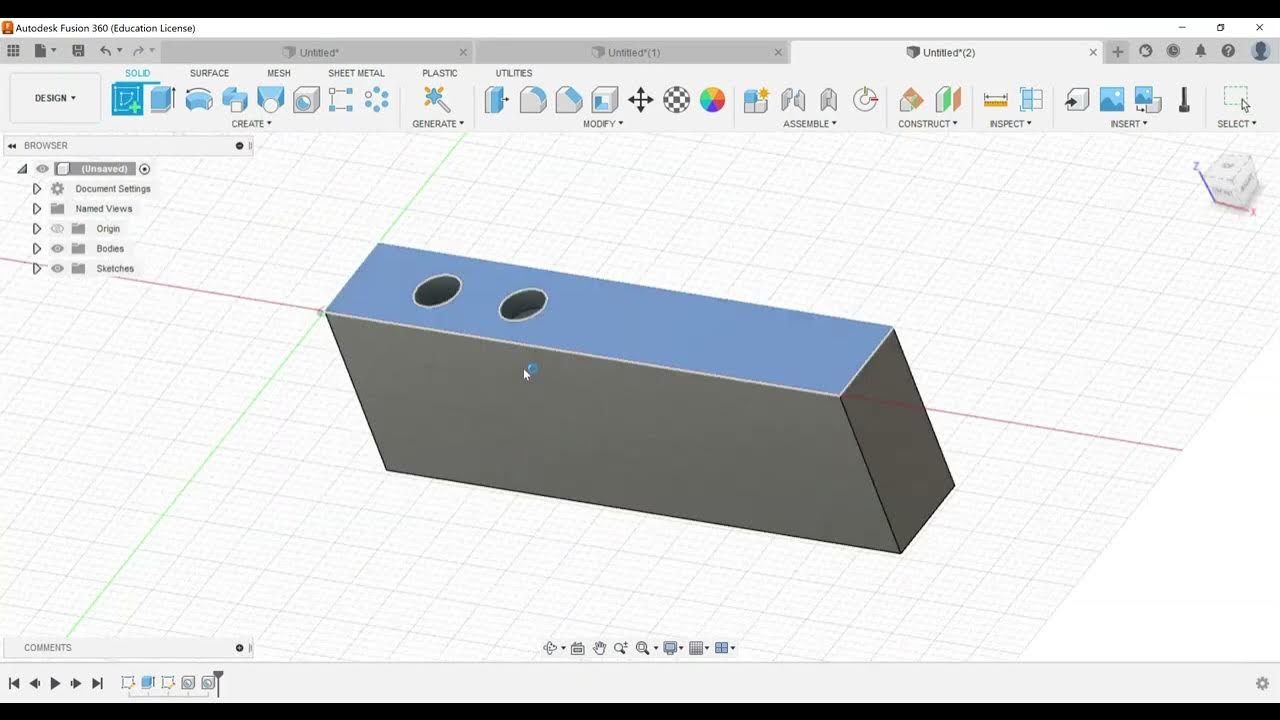

- ✂️ The shell command allows users to remove selected faces (like the top face of a cylinder) to create hollow structures, such as a cup.

- ⚙️ The shell thickness can be adjusted for both inside and outside walls, with an example of 0.125 inches for the thickness of the shell.

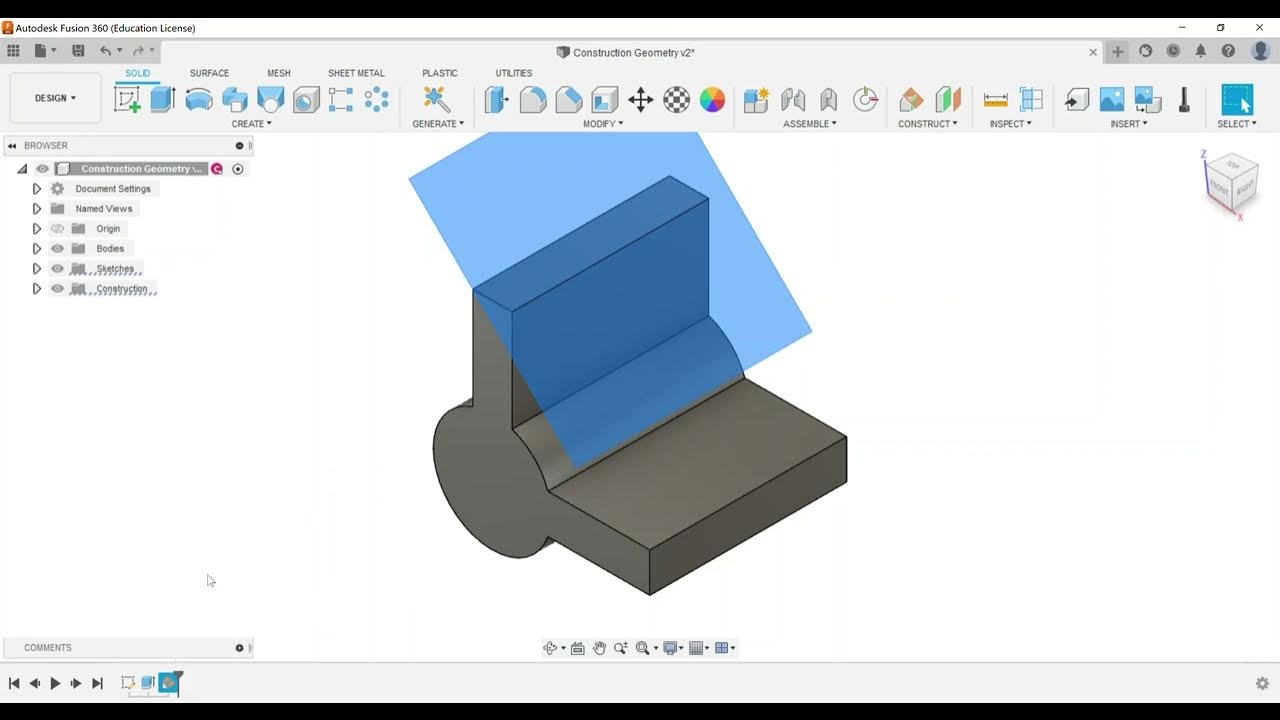

- 🛠️ Section analysis is used to visualize the shell and assess the thickness of the walls inside the model.

- 🔄 Users can undo or delete the shell feature to return the object to its original solid form and try different shell settings.

- 🔍 Another method is to shell the entire body without removing any faces, which results in a hollow object without altering the outer appearance.

- 📏 Section analysis can also be applied to measure dimensions like the distance from the center of the part to the edge.

- 📚 The video encourages viewers to keep practicing these techniques for the Autodesk Fusion 360 Certified User (ACU) Exam.

Q & A

What is the focus of the video in relation to the Autodesk Fusion 360 Certified User Exam?

-The video focuses on preparing for the Autodesk Fusion 360 Certified User Exam by discussing the shell feature, which is part of the exam's part modeling section.

How do you create a basic 3D model for shelling in Fusion 360?

-To create a basic 3D model, start by creating a sketch of a cylinder (5 inches in diameter), extrude it to about 4 inches, and then use the shell feature to hollow it out.

What does the shell feature in Fusion 360 do?

-The shell feature in Fusion 360 hollows out a solid body by removing one or more faces and creating a uniform wall thickness for the remaining part.

How can you apply the shell feature to create a container-like shape?

-To create a container shape, select the top face of the cylinder, apply the shell feature, and set the inside wall thickness (e.g., 0.125 inches). This removes the top face and hollows out the rest of the object.

What is the difference between setting an inside thickness and an outside thickness when using the shell feature?

-Setting an inside thickness reduces the material from the inside of the object, while setting an outside thickness removes material from the outer surface. You can also combine both for custom wall thickness.

What is the purpose of the section analysis tool in Fusion 360?

-The section analysis tool allows you to cut through the object to visualize and inspect the internal structure of a model, including the effects of the shell feature.

What is the benefit of using the shell feature for 3D printing purposes?

-The shell feature can reduce print time and material usage by hollowing out the object, though it may result in a less structurally strong model.

How do you shell an entire body without removing any faces in Fusion 360?

-To shell an entire body without removing faces, simply select the body instead of individual faces, and set the desired wall thickness. The object will be hollow inside, but its outer shape remains intact.

What happens when you use the shell feature but don’t remove the top face of the cylinder?

-If you don’t remove the top face, the shell feature will hollow out the interior of the cylinder, but the top surface will remain, creating a completely closed hollow object.

Why is the shell feature important for the Autodesk Fusion 360 Certified User Exam?

-The shell feature is important because it is frequently tested in the exam, requiring candidates to demonstrate their ability to hollow out objects, use section analysis, and measure dimensions of the shelled part.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)