How to Solder Electronics

Summary

TLDRThis video explains the basics of electronic soldering, covering essential topics like the importance of flux, selecting the right tip size, and how to avoid common mistakes. It addresses key questions such as the safety of fumes, proper cleaning, and tinning of the iron tip, and why direct heat application is crucial for strong joints. The video emphasizes the significance of clean, well-heated components for reliable solder connections and offers practical tips on how to solder efficiently, prevent overheating, and clean the joint after soldering to ensure durability and safety.

Takeaways

- 🛠️ Soldering Tip: Avoid putting solder on the iron tip first and carrying it to the joint, as it leads to weak and unreliable connections.

- 🔥 Proper Heating: Solder won't adhere if the parts aren't hot enough or are covered in oxidation. Heat both components evenly for a strong connection.

- 🧪 Flux Importance: Flux is essential for removing oxidation and helping solder flow. Most solder wire has flux inside to prevent oxidation during the soldering process.

- 💨 Fume Safety: Lead fumes are unlikely at normal soldering temperatures, but solder fumes can cause long-term respiratory issues like occupational asthma. Work in a well-ventilated area.

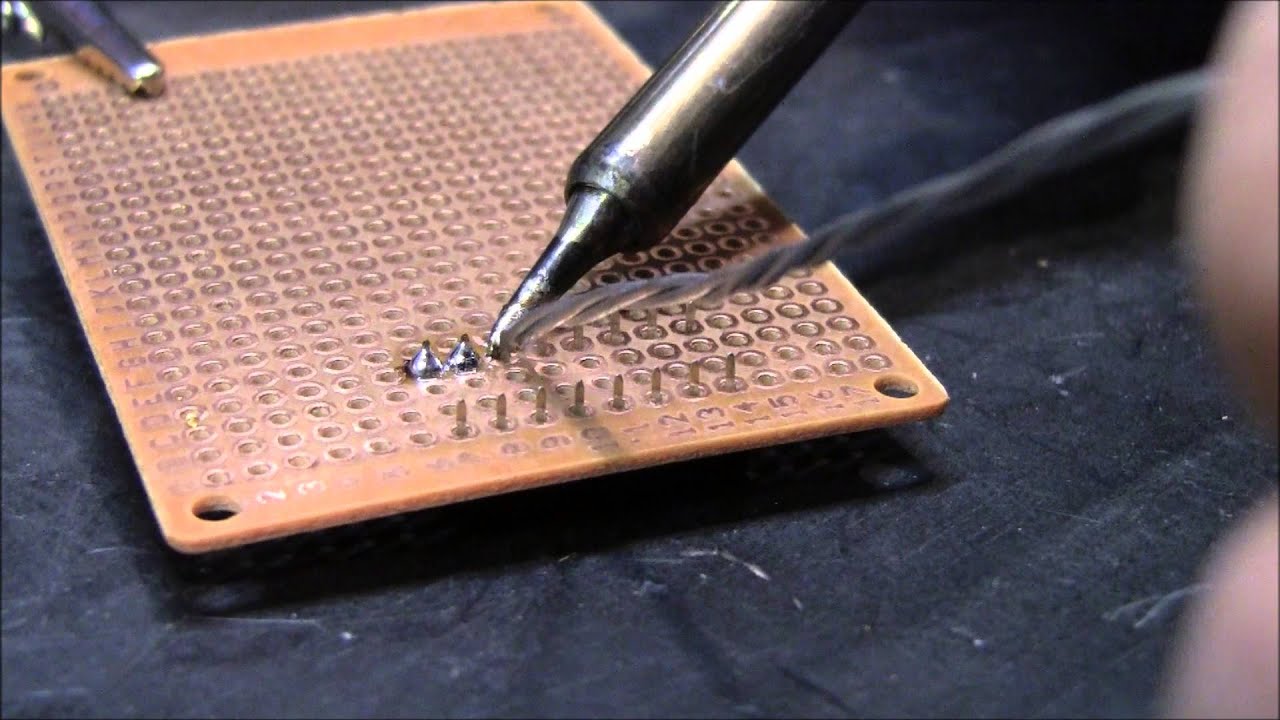

- 🔧 Proper Soldering Technique: Use a clamp to hold components, apply heat to both the pad and lead, and add solder to the opposite side of the connection for even heat distribution.

- ⚡ Clean the Tip: A clean iron tip is crucial for effective heat transfer. Clean it with a damp sponge or dry cleaner, and re-tin it with solder to prevent oxidation.

- 🔬 Joint Inspection: A good solder joint forms a metallurgical bond and should appear smooth, shiny, and ramp-like. Dull, cold joints indicate poor soldering.

- ⏳ Timing Matters: Aim to complete a solder joint within 2 to 5 seconds for small components. Prolonged heating can damage the components or make the joint brittle.

- 🌡️ Heat Sensitivity: Use heat sinks to protect sensitive components like diodes and transistors from overheating during soldering.

- 🧼 Post-Solder Cleaning: Clean the joint with alcohol or another cleaner to remove corrosive flux residues, unless you're using no-clean flux, which doesn't require cleaning.

Q & A

What is the correct way to apply solder to a joint?

-The correct way is to heat both the component and the pad first, then apply solder between the tip and the connection to create a heat bridge. Apply solder to the opposite side of the connection, ensuring both parts are hot enough for the solder to bond properly.

Why is applying solder to the iron tip first ineffective?

-Applying solder to the iron tip first is ineffective because the flux inside the solder boils off before it touches the joint, and solder may not transfer well to the connection. This leads to unreliable joints that are prone to breaking.

What is flux, and why is it important in soldering?

-Flux is a weak acid that removes oxides from the metal surfaces, allowing the solder to adhere. It also prevents further oxidation by keeping oxygen away until the solder displaces it, and helps to distribute heat by reducing surface tension.

Can you get lead poisoning from soldering fumes?

-At typical soldering temperatures (600-750°F), lead poisoning is unlikely since lead boils at over 3000°F. However, fumes from flux can still be harmful and long-term exposure to solder fumes can cause occupational asthma.

What are the dangers of soldering at higher temperatures?

-At temperatures above 850°F, lead can atomize more easily, making it possible to inhale small lead particles. Additionally, overheating parts can cause them to oxidize faster or damage sensitive components like diodes and transistors.

Why is it necessary to clean and tin the iron tip regularly?

-Cleaning and tinning the iron tip removes oxides and charred flux that reduce the tip's ability to transfer heat. Tinning the tip also protects it from further oxidation and helps it transfer heat more effectively to the joint.

What should be done if parts have heavy oxidation before soldering?

-If parts are heavily oxidized, it is recommended to clean them with fine grit sandpaper or another abrasive to remove the oxide layer. This ensures that the solder can adhere properly to the clean metal surfaces.

How can you prevent cold or disturbed solder joints?

-To prevent cold or disturbed joints, ensure the parts are properly heated before applying solder, avoid moving the joint while the solder is cooling, and clean surfaces to remove oxides or dirt that may prevent solder from bonding.

What tip size and shape should be used for soldering?

-You should use the largest tip that can heat only a single joint, slightly smaller than the pad. Larger tips transfer heat faster and hold more heat. Chisel-shaped tips provide more surface area for faster heating.

Why is it important to solder quickly, especially with lead-free solder?

-Soldering quickly is important to avoid overheating components and making the joints brittle. Lead-free solder takes longer to wet and adhere to metals, so extra care must be taken to heat the joint enough without prolonged exposure.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

5.0 / 5 (0 votes)