DIY 2005 Hyundai Tucson Alternator Replacement

Summary

TLDRThis video script details a DIY guide to replacing the alternator in a 2005 Hyundai Tucson. The process begins with diagnosing alternator failure through warning signs like dashboard lights. The tutorial covers jacking up the car, removing the front passenger tire, and detaching the battery. It proceeds with releasing the belt tension, disconnecting wires, and removing the faulty alternator. The script then guides through installing the new alternator, reconnecting wires, and adjusting the belt. Finally, it advises on jump-starting the car due to a drained battery and emphasizes the importance of safety and correct tool usage throughout the repair.

Takeaways

- 🔌 The video is about changing the alternator on a 2005 Hyundai Tucson due to warning signs like dashboard lights indicating a problem.

- 🚦 The alternator failure was confirmed when the car's lights dimmed and eventually died, necessitating a tow.

- 🔧 The first step was to jack up the car and remove the front passenger side tire to access the alternator.

- 🔨 Loosening the lug nuts before lifting the car off the ground was recommended for safety and ease of tire removal.

- 🛠️ The alternator was accessed by removing a plastic guard and disconnecting the battery's negative terminal.

- 🔄 The alternator pulley tension was released to remove the belt, a crucial step before alternator removal.

- 🔌 Disconnecting the wires from the alternator involved removing clips and unplugging a wire harness and a power plug.

- 🔩 The alternator was removed by loosening two main bolts, one of which required a torque wrench for proper removal.

- 🛡️ The alternator was covered in grease, possibly from a power steering fluid leak, indicating a potential cause of failure.

- 🔄 The installation of the new alternator involved reversing the removal process, including reconnecting wires and bolts.

- 🔋 After installation, the car needed to be jump-started due to the battery being drained, highlighting the importance of a functioning alternator for battery charging.

Q & A

What is the main issue described in the video script?

-The main issue described in the video script is the failure of the alternator in a 2005 Hyundai Tucson, which is causing warning lights on the dashboard and eventually leading to the car dying.

What are the warning signs that indicate a problem with the alternator?

-The warning signs include the 'check engine' light and the battery light coming on the dashboard, as well as the car's electrical systems such as the dashboard lights and headlights dimming before the car dies.

What diagnostic was performed to confirm the alternator issue?

-A diagnostic test was run at AutoZone to confirm that the alternator was the problem.

Why did the car need to be towed home?

-The car needed to be towed home because the alternator failed, causing the car to lose power to its electrical systems and ultimately die while driving.

What is the first step in the alternator replacement process shown in the video?

-The first step is to jack up the car and remove the front passenger side tire to access the alternator.

What tools are needed to remove the alternator?

-Tools needed include a jack, jack stands, a tire iron, a ratchet, and various socket wrenches (10mm, 13mm, and 9/16).

How many bolts and what types of connections need to be removed to access the alternator?

-There are two main bolts that hold the alternator, a wire harness clip, and a plug that needs to be disconnected.

What is the purpose of releasing tension on the tensioner pulley?

-Releasing tension on the tensioner pulley allows the belt to be removed from the alternator, which is necessary for its replacement.

What is the challenge faced when trying to remove the alternator?

-The challenge is the limited space to maneuver tools and hands, especially when trying to disconnect the electrical plug and tighten the bolts.

What is the procedure for installing the new alternator?

-The procedure involves positioning the new alternator, connecting the electrical plug and wire harness, and securing it with the appropriate bolts, followed by tightening them to the specified torque.

What is the final step before starting the car after the alternator replacement?

-The final step is to reconnect the battery terminals and ensure all components are in place before attempting to start the car.

How is the car jump-started after the battery has been depleted?

-The car is jump-started by connecting jumper cables from a live car to the dead car's battery terminals, starting the live car, and then attempting to start the dead car.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Hyundai Tucson Alternator Change, Part1

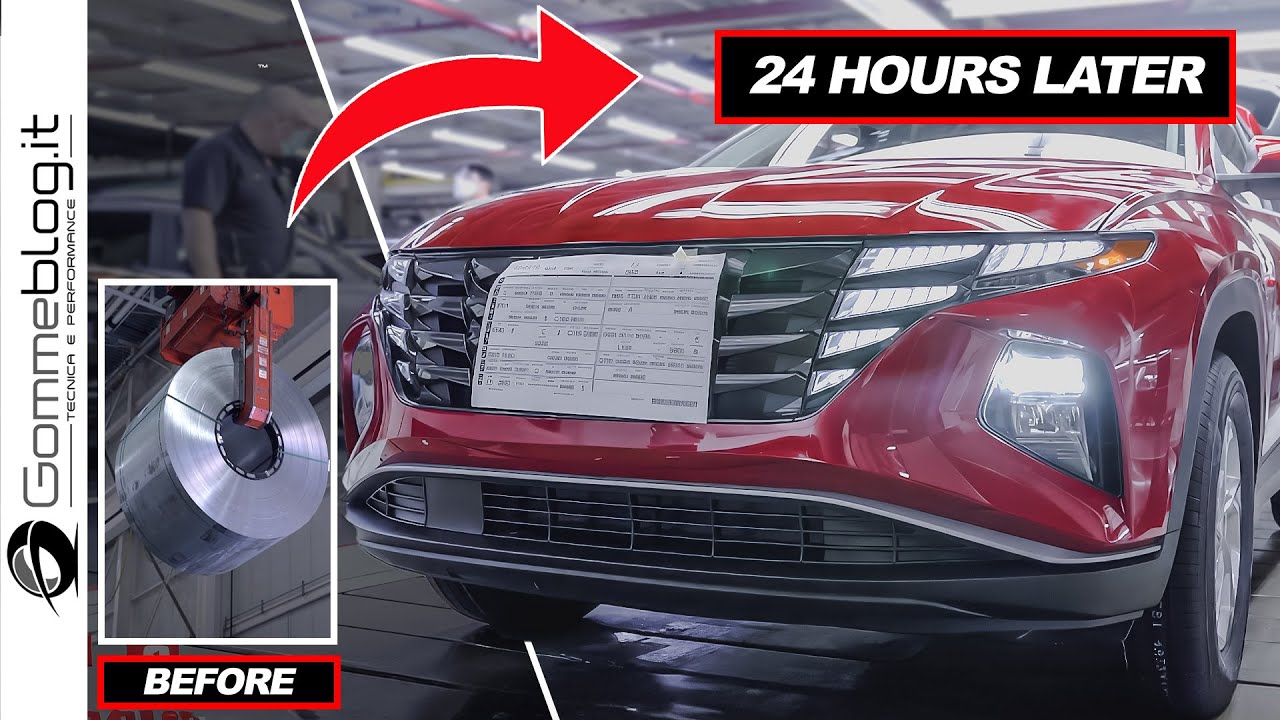

What's REALLY Happening Inside Hyundai's TUCSON Manufacturing Plant

2005-2008 Hyundai Tucson Exhaust Leak Repair | V6 FWD

✅Por 50 Millones ¿Qué es Mejor [Duster -Tucson - S Cross]😅

2006 Hyundai Tucson 2.7 V6 Alternator Replacement Without Removing Cv Axel Or Other Suspension Parts

MA AUDI A3 AVEC 500000 KM EST COMME NEUVE ! ( bon j’ai tout changé.. 😅)

5.0 / 5 (0 votes)