2005-2008 Hyundai Tucson Exhaust Leak Repair | V6 FWD

Summary

TLDRIn this garage workshop video, the host tackles an exhaust leak on his wife's 2006 Hyundai Tucson. Initially, he mistakenly orders the wrong exhaust part for the front-wheel drive model but ingeniously adapts it by cutting and welding. With the help of a newly acquired MIG welder, he replaces the faulty flex joints, ensuring a tight seal with high-temperature gasket maker. After a meticulous installation and letting the RTV gasket maker cure overnight, the repair is tested with a successful first startup, demonstrating a practical DIY solution for a common car issue.

Takeaways

- 🔧 The video is about fixing an exhaust leak on a 2006 Hyundai Tucson V6, which is the 'beater car' of the narrator's wife.

- 🛠️ The narrator ordered the wrong exhaust part, mistaking it for the correct one due to a misunderstanding of the differences between front-wheel and all-wheel drive models.

- 🔄 The main difference between the two exhaust parts is the angle of the bend near the exhaust manifold, with a 90° bend for front-wheel drive and a 45° bend for all-wheel drive.

- 👷♂️ The narrator plans to rectify the mistake by cutting and welding the 90° bend from the old exhaust onto the new one.

- 🚧 The narrator purchased a new MIG welder, the Prime Weld Mig 180, to perform the repair, which was a long-considered purchase.

- 🔩 The repair involves removing six bolts at three connection points, which are likely rusted and will require careful handling.

- 🔍 Upon removing the old exhaust, it was discovered that the leak was coming from a failing front flex joint that fell apart.

- 🧩 The narrator noticed that the hardware kit for the new exhaust might be missing some parts, specifically larger nuts for the rear connection.

- 🛠️ The repair process includes cleaning up rusted threads with a tap and die set and ensuring the correct size nuts are used for a secure fit.

- 🔨 The narrator uses a chisel and hammer to remove old gasket material and plans to use high-temperature exhaust gasket maker for a better seal.

- 🔧 After welding the old 90° bend onto the new exhaust, the narrator applies high-temperature RTV gasket maker to ensure no leaks post-installation.

- 🚗 The final step includes bolting the new exhaust system in place, allowing the RTV to cure overnight, and testing for leaks with a startup the next day.

Q & A

What is the main issue the narrator is addressing in the video?

-The main issue is an exhaust leak in the narrator's wife's 2006 Hyundai Tucson front-wheel drive car.

Why is the car referred to as a 'beater car'?

-The car is called a 'beater car' because it is being used as a temporary vehicle while the wife's other car is broken down.

What mistake did the narrator make when ordering the exhaust part?

-The narrator ordered the wrong exhaust part, not realizing there is a difference between the exhaust systems for front-wheel drive and all-wheel drive Tucson models.

What is the difference between the exhaust parts for front-wheel drive and all-wheel drive Tucson models?

-The difference is in the angle of the bend where the exhaust connects to the exhaust manifold; it's a 90° bend for front-wheel drive and a 45° bend for all-wheel drive.

What tool did the narrator purchase to fix the exhaust issue?

-The narrator purchased a Prime weld MIG 180 welder to cut and weld the exhaust parts.

How did the narrator ensure the car was stable while working on it?

-The narrator used two 6-ton jack stands under the frame rail and a jack under the frame as a backup safety measure.

What was the source of the exhaust leak identified by the narrator?

-The exhaust leak was coming from the front flex joint and possibly other pinholes in the exhaust system.

What additional items did the narrator need to purchase for the repair?

-The narrator needed to purchase M12 by 1.5 nuts, gasket maker, and a new grinder disc.

How did the narrator plan to correct the mistake of ordering the wrong exhaust part?

-The narrator planned to cut the 90° bend from the old exhaust and weld it onto the new exhaust part to make it fit correctly.

What safety measure did the narrator take before fully installing the exhaust system?

-The narrator planned to apply high-temperature exhaust gasket maker on both sides of the gaskets to ensure a good seal and prevent leaks.

What was the final step before starting the car after the repair?

-The final step was to let the high-temperature RTV gasket maker cure overnight before starting the car to check for leaks.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

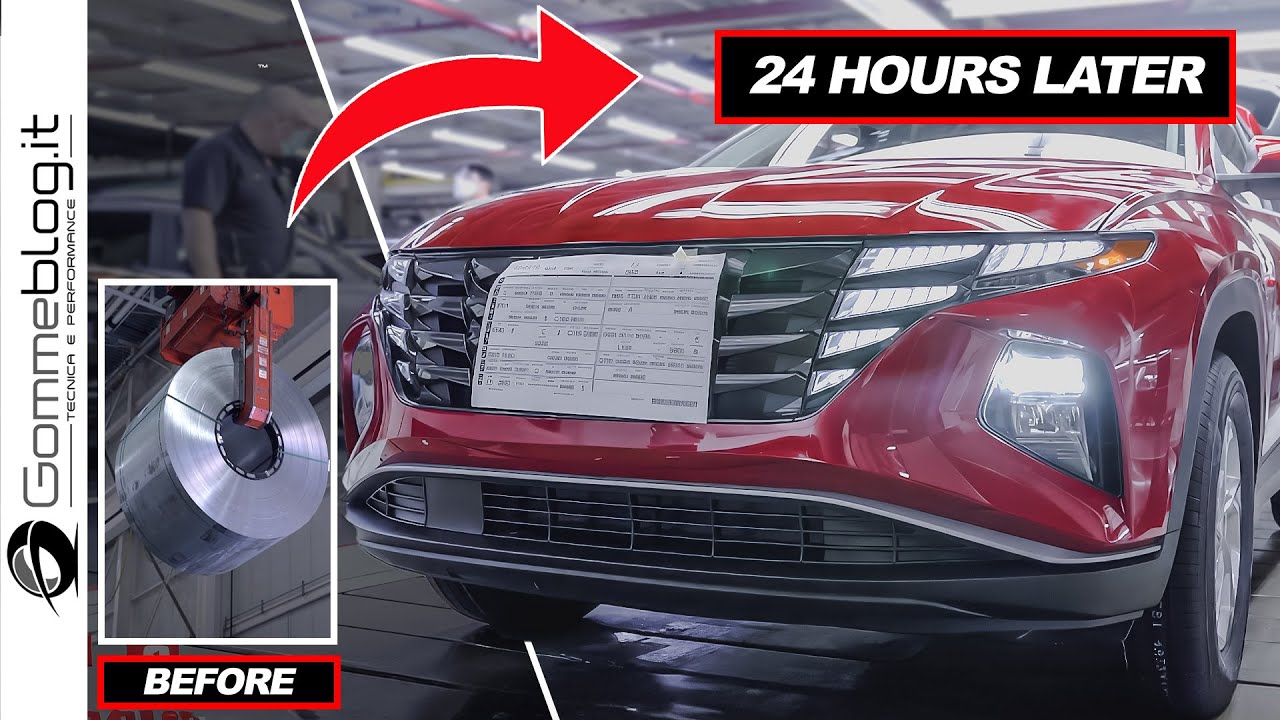

What's REALLY Happening Inside Hyundai's TUCSON Manufacturing Plant

Złomnik: kupiłem bezsensowny samochód GRANDAUER

Sem título? O título é Sem título.

ESCAPE FORTUNA DA 160 NA SAHARA 300 RALLY - FICOU FORTE 🔥

Je transforme mon château en garage de rêve !

Snapped coil spring replacement HYUNDAI TUCSON #hyundai #tucson #snappedcoilspring

5.0 / 5 (0 votes)