Hyundai Tucson Alternator Change, Part1

Summary

TLDRIn this video, the creator demonstrates how to replace the alternator on a 2005 Hyundai Tucson V6 2.7L. Due to a lack of helpful guides, he decided to make one himself. He details the process, starting with charging the battery, removing the passenger side tire, and accessing the alternator through a cramped space. He explains the challenges faced, such as removing a specific bolt, and provides tips for reinstallation. The video emphasizes the importance of proper jacking and safety precautions while working under the vehicle.

Takeaways

- 🔋 The video is a tutorial on replacing the alternator of a 2005 Hyundai Tucson V6 with a 2.7-liter engine.

- 🛠️ The first step is to ensure the car's battery is fully charged before starting the process.

- 🔧 Removing the passenger side tire and plastic cover is the easiest way to access the alternator.

- 🔩 A bolt in a U-shaped bracket is the most challenging part to remove during the alternator extraction.

- 🔄 The alternator sits differently compared to most, with a unique installation method involving a round hole and slide mechanism.

- 🚫 The video creator initially struggled to remove the alternator due to a metal bracket obstructing its path.

- 🔌 Two cables need to be disconnected from the alternator, one being the electrical connector and the other for the battery.

- 🛡️ The battery cable has a rubber cover and is secured with a bolt once connected to the alternator.

- 💰 The alternator was rebuilt locally for a third of the cost of a new one, saving the creator significant money.

- 🔄 The rebuilt alternator comes with a one-year warranty and is visually indistinguishable from a new one.

- 🏎️ The installation process involves maneuvering the alternator into a tight space and reconnecting the cables carefully.

Q & A

What is the vehicle and engine type discussed in the video?

-The video discusses replacing the alternator on a 2005 Hyundai Tucson with a V6 2.7-liter engine.

What is the first step before starting the alternator replacement?

-The first step is to charge the battery fully before beginning the alternator replacement.

Why is it necessary to remove the passenger side tire and plastic cover?

-Removing the passenger side tire and plastic cover provides easier access to the alternator for removal and installation.

What makes removing the bolt from the alternator challenging?

-The bolt is difficult to remove because it hits a metal bracket, which is part of the suspension system, and requires significant force or heat to loosen.

How does the speaker suggest managing the tight space when disconnecting the alternator cables?

-The speaker suggests having small hands to reach in and using a long screwdriver to push and pry on the electrical connector while pushing the button to disconnect it.

What type of alternator is being installed as a replacement?

-A rebuilt alternator, which was rebuilt by a local shop and costs significantly less than a brand new one, is being installed.

How should the vehicle be supported during the alternator replacement process?

-The vehicle should be supported with a hydraulic jack, axle scissors jack, and a tower under the car to ensure safety and stability.

What is the purpose of keeping the suspension arm elevated with a hydraulic jack?

-Keeping the suspension arm elevated with a hydraulic jack prevents it from dropping down, providing necessary space to maneuver and preventing any parts from falling apart.

What does the speaker recommend doing first when installing the new alternator?

-The speaker recommends hooking up the battery cable with the rubber cover to the alternator first.

Why does the speaker suggest skipping the video footage of maneuvering the alternator into place?

-The speaker suggests skipping this part to save time, acknowledging that viewers will also struggle with the tight space and will need to find their own way to maneuver the alternator into place.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

DIY 2005 Hyundai Tucson Alternator Replacement

Snapped coil spring replacement HYUNDAI TUCSON #hyundai #tucson #snappedcoilspring

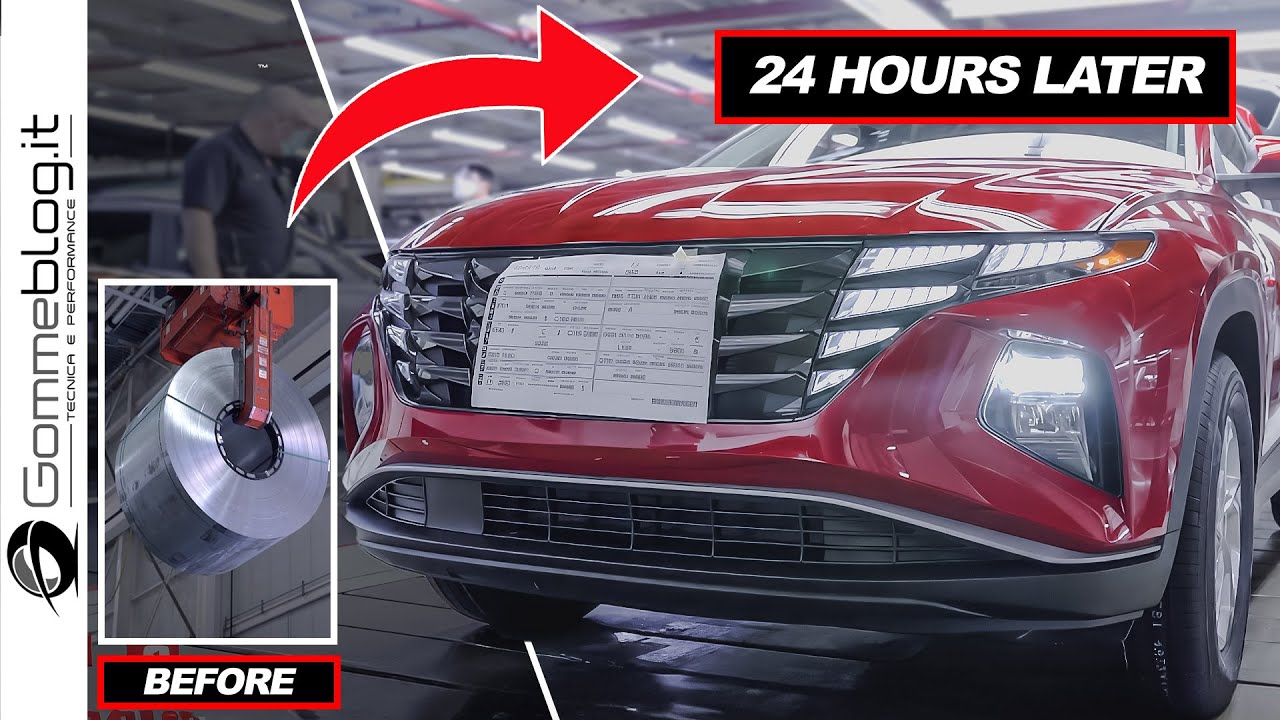

What's REALLY Happening Inside Hyundai's TUCSON Manufacturing Plant

2006 Hyundai Tucson 2.7 V6 Alternator Replacement Without Removing Cv Axel Or Other Suspension Parts

✅Por 50 Millones ¿Qué es Mejor [Duster -Tucson - S Cross]😅

How to Test an Alternator

5.0 / 5 (0 votes)