Assembly Drawing N3/7 August 2024/Part 1️⃣

Summary

TLDRIn this detailed tutorial, the instructor walks viewers through the step-by-step process of correcting and drawing engineering components from a cam pulley assembly. Focusing on key items like item 1, item 2, and item 4, the tutorial emphasizes dimensions, projections, and the importance of aligning parts accurately. Viewers learn how to interpret technical drawings, handle internal threading, and work with scale measurements. The instructor also highlights how to approach sectional views and the significance of understanding assembly alignment. This video serves as a guide for students and professionals to master engineering drawing techniques.

Takeaways

- 😀 The script is a tutorial for correcting and drawing a cam pulley assembly based on a previous engineering drawing exam from August 2024.

- 😀 The key focus of the video is to provide a step-by-step correction and assembly process of a cam pulley, with emphasis on different items and their measurements.

- 😀 A part list is essential for the drawing; it includes item descriptions, quantities, and specifications for each part.

- 😀 Item 6 (M12 hexagonal head bolt) needs to be drawn twice, while the M2 hexagonal nut (item 8) is not shown in the drawing.

- 😀 The assembly uses the first angle graphic projection method, where views are interpreted in a landscape format, and projections are based on these views.

- 😀 The process includes creating faint lines, applying scales, and positioning dimensions accurately, such as the 68mm and 130mm horizontal and vertical measurements for item one.

- 😀 The fully sectional front view is key in the drawing; hidden lines are considered when parts are cut to expose internal details, and some lines may disappear when sectioned.

- 😀 The tutorial stresses the importance of matching the shape and dimensions of the components being assembled to ensure proper fitting.

- 😀 The instructor provides tips for drawing accurately, such as adjusting for radius and avoiding sharp corners unless specified, as seen in item four (chem shaft).

- 😀 Throughout the tutorial, various dimensions are repeatedly checked and adjusted, including 24mm, 44mm, and 50mm, to ensure proper assembly and measurements.

- 😀 The drawing includes internal threads, which need to be positioned correctly and acknowledged in the diagram, such as for item four (chem shaft).

Q & A

What is the main focus of this YouTube video?

-The main focus of the video is correcting an engineering drawing for a cam pulley assembly. The instructor explains how to correctly interpret the views and dimensions of various parts, as well as the process of drawing them step-by-step.

What is the significance of the part list in the drawing process?

-The part list is crucial because it provides the descriptions, quantities, and required parts for the assembly. Without the part list, it's impossible to accurately complete the drawing or determine how many times each item should be drawn.

What does the term 'fully sectional front view' mean in this context?

-A 'fully sectional front view' refers to a drawing that shows a complete cutaway of the assembly from the front, exposing the internal details. This is done to give a clear view of the internal features that would not be visible from an external perspective.

Why are some lines drawn faint and others dark in the process?

-Faint lines are used for construction or reference, marking positions without finalizing them. Dark lines, on the other hand, are used to indicate the actual boundaries and features of the component after dimensions and other details are finalized.

What does the first angle projection symbol indicate in this video?

-The first angle projection symbol indicates that the drawing follows the first angle projection method, which is a system used in technical drawings to represent the 3D shape of an object in 2D views. The views are typically oriented with the front view at the center and the other views placed around it.

What is the significance of dimensioning items like '68 mm' and '130 mm'?

-The dimensions, such as '68 mm' and '130 mm', are critical for properly scaling the drawing. They ensure that the size and positioning of each part are accurate and correspond to the real-world measurements for manufacturing or assembly.

Why is the dimension 'M12 hexagonal head B' drawn twice?

-The 'M12 hexagonal head B' needs to be drawn twice because it is used in two locations in the assembly. This is indicated by the part list, which specifies that this item should appear twice in the drawing.

What is the reason for using radius and diameter measurements, like 'radius 17 mm' and 'diameter 24 mm'?

-Radius and diameter measurements are used to define the size of circular features, such as holes, shafts, and other round components. These measurements are critical to ensure that the parts fit together properly in the assembly.

What does the mention of 'internal thread' imply in the drawing process?

-The mention of an 'internal thread' implies that the part has a threaded hole or bore that is used to accommodate a screw or bolt. This feature must be clearly represented, and the dimensions for it, such as the diameter and depth, must be accurately shown.

How does the instructor handle errors in the drawing process?

-The instructor makes corrections during the drawing process, such as erasing or adjusting lines, to ensure that the dimensions and features align properly. This iterative approach ensures accuracy and adherence to the specifications.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

PEN in | Autodesk Inventor CAD

Submersible pump Design ||part 1-Empellar ||Solidworks Tutorial ||

Integral de la exponencial | Integrales por Sustitución - Cambio de variable | Ejemplo 14

Tutorial Cara Merakit DIY KIT Robot Line Tracer Follower Cocok Untuk Pemula Belajar Solder Edukasi

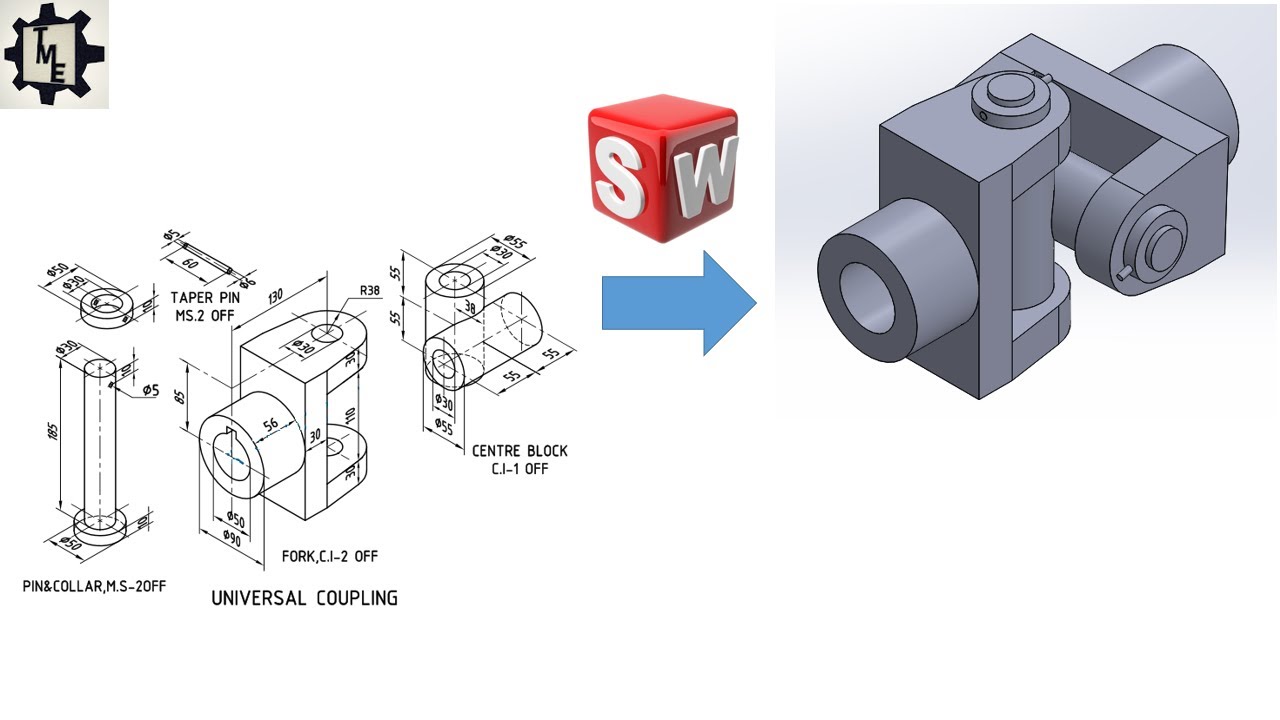

Universal Coupling using SOLIDWORKS | Part and Assembly Modelling | Tutorials for beginners

8. Cara Mudah Program PLC Untuk Pengendalian Sistem Elektropneumatik

5.0 / 5 (0 votes)