DROP HAMMER & MINI PILE

Summary

TLDRThis video explains the process of mini pile driving using a drop hammer, commonly used for small to medium-scale projects. The method involves preparing the site by clearing debris, positioning the mini piles, and using a drop hammer to repeatedly strike the pile, driving it into the ground until it reaches the desired depth or resistance. The video also covers the steps of connecting pile segments if needed and verifying the depth and position of the piles to ensure they meet design specifications, ensuring adequate soil support.

Takeaways

- 😀 Mini pile with drop hammer is a common method for piling in small to medium-scale projects.

- 😀 Mini piles typically have a small diameter (20-30 cm) and are suitable for areas with limited space or low bearing capacity soil.

- 😀 Drop hammer is a tool used to drive piles, either manually or mechanically, by dropping a weight from a certain height.

- 😀 The process starts with site preparation, which involves clearing the area of any obstructing materials and determining the pile positions according to structural designs.

- 😀 Piles are placed upright at predetermined positions using a water level or other measurement tools.

- 😀 The drop hammer is lifted to a specified height, and the weight is repeatedly dropped to drive the pile into the ground.

- 😀 The process continues until the pile reaches the required depth or resistance, typically measured by the penetration per blow.

- 😀 If the pile doesn't reach the required depth, additional pile segments are joined using connection plates or welding.

- 😀 The depth and position of the pile are rechecked to ensure they align with the design specifications.

- 😀 Penetration per blow is recorded to confirm the soil's bearing capacity and the pile's effectiveness.

Q & A

What is a mini pile and what are its typical dimensions?

-A mini pile is a type of small-diameter pile, typically ranging from 20 to 30 cm in diameter. It is commonly used in small to medium-scale projects, especially in areas with limited space or low-bearing soil conditions.

What is the role of a drop hammer in the mini pile installation process?

-A drop hammer is a tool used to drive mini piles into the ground by dropping a heavy weight from a certain height. The impact of the hammer helps press the pile into the soil, with the process being repeated until the pile reaches the desired depth or resistance.

How is the drop hammer lifted during the installation process?

-The drop hammer is lifted to a specific height using a pulley system or other mechanical mechanisms before being released to fall onto the pile.

What is the purpose of cleaning the site before starting the mini pile installation?

-The site is cleared of any obstructing materials to ensure that the pile can be accurately placed and driven into the ground without interference from debris or other obstacles.

How is the position of the pile determined before installation?

-The position of the mini pile is determined according to the design specifications of the structure, and it is marked or measured using a water level or other measuring tools to ensure proper alignment.

What happens if the mini pile does not reach the required depth after initial hammering?

-If the pile does not reach the desired depth, additional segments of the pile can be added by connecting them with joining plates (Gin plates) or welding to extend the pile and achieve the required depth.

How is the depth of the pile monitored during installation?

-The depth of the pile is monitored by checking its penetration through the soil. The number of hammer blows (penetration per blow) is typically recorded to track the progress and ensure the pile reaches the required depth or resistance.

What ensures the stability and alignment of the mini pile during installation?

-The stability and alignment of the mini pile are ensured by using a water level or other alignment tools to keep the pile perpendicular to the ground as it is driven into the soil.

How is soil resistance measured during the mini pile installation?

-Soil resistance is measured by calculating the penetration rate of the pile with each blow of the hammer. The number of blows per unit of depth helps assess the soil's bearing capacity and indicates when the pile has reached the necessary resistance.

What is the final step after the mini pile installation process?

-After the mini pile has been driven to the required depth and resistance, the final checks are made to ensure the pile's position and depth conform to the design specifications. Penetration data is reviewed to confirm the soil's bearing capacity.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

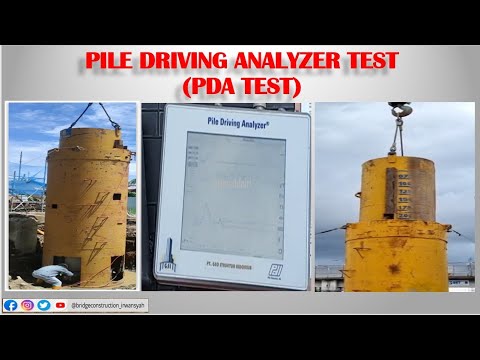

Pekerjaan PDA Tes Pada Borepile by IRWANSYAH

Pile Driving Equipment Selection and Penetration Limitations | Pile Driving Series #2

PROSES PEMANCANGAN TIANG PANCANG BETON‼️PART 1

How does MBBR work? Full description of moving bed biofilm reactor wastewater treatment plants

METODE PELAKSANAAN PONDASI TIANG PANCANG

Pile Foundation and It's Types | Bridge Engineering | Lec - 05

5.0 / 5 (0 votes)