Pile Driving Equipment Selection and Penetration Limitations | Pile Driving Series #2

Summary

TLDRThis video from Pyle Buck's pile driving series offers an in-depth look at the evolution and selection of pile driving equipment. Viewers will learn about the transition from manual methods to advanced hydraulic and vibratory hammers, alongside the components of a typical pile driving system. Key considerations for selecting a hammer based on pile type, soil conditions, and project requirements are discussed, highlighting the importance of monitoring penetration rates to prevent overdriving. The video aims to equip viewers with essential knowledge for effective and efficient pile driving practices.

Takeaways

- 😀 Pile driving equipment has evolved from manual hammers to advanced hydraulic and vibratory systems, increasing efficiency and precision.

- 🔧 The typical pile driving system consists of components such as piles, hammers, leads, cushions, helmets, power sources, and monitoring equipment.

- 📈 Selecting the right pile hammer depends on factors like pile type, soil conditions, driving methods, and required driving force.

- 🌍 Urban sites may require vibratory hammers to minimize noise and vibration, making them suitable for sensitive environments.

- ⚡ Hydraulic hammers are generally more energy-efficient compared to diesel hammers, offering better performance in many situations.

- 📊 Monitoring penetration rates is crucial to ensure piles reach the required depth without being overdriven, which can cause damage.

- 🔍 Blow counts are recorded to assess the driving process and avoid overdriving, helping maintain structural integrity.

- 🛠️ Access and mobility at the site can influence the choice of hammer size and type, impacting setup and operation.

- 💰 Cost considerations are important; options include new, used, or rental hammers, depending on budget constraints.

- 🔒 Personal protective equipment (PPE) is essential for safety during pile driving operations, protecting workers from potential hazards.

Q & A

What is the main focus of the video series?

-The main focus of the video series is to cover all aspects of pile driving, including equipment types, methods, accessories, and other related topics.

What key development marked the evolution of pile driving equipment in the late 1800s?

-The introduction of steam-powered hammers, which utilized steam pressure to drive piles, marked a key development in the late 1800s.

How did diesel-powered hammers improve pile driving efficiency?

-Diesel-powered hammers provided greater driving force compared to earlier methods, which improved overall efficiency during the pile driving process.

What is the purpose of hydraulic hammers introduced in the 1950s?

-Hydraulic hammers were introduced to offer more precise and efficient pile driving by using hydraulic pressure instead of traditional methods.

What advantage do vibratory hammers provide in certain situations?

-Vibratory hammers are advantageous in environments where minimizing noise and vibration is critical, such as urban areas.

What are the key components of a pile driving system?

-Key components include the pile, hammer, leads, cushion, helmet, power source, monitoring equipment, rigging, and personal protective equipment (PPE).

What factors should be considered when selecting a pile hammer?

-Factors include pile type and properties, soil conditions, driving method, required driving force, energy efficiency, access and mobility, noise and vibration levels, and cost.

What is the significance of monitoring penetration rates during pile driving?

-Monitoring penetration rates is crucial to prevent overdriving, which can cause permanent damage to the pile structure.

What potential issue can occur during pile driving if the pile encounters hard ground?

-If the pile encounters hard ground, it may lead to a condition known as refusal, where the pile cannot penetrate further, potentially causing damage.

How does ECA Equipment Corporation contribute to the pile driving industry?

-ECA Equipment Corporation has been a provider of heavy construction equipment since 1918, offering advanced and reliable foundation equipment for contractors.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

METODE PELAKSANAAN PONDASI TIANG PANCANG

DROP HAMMER & MINI PILE

OH BEGINI!! PROSES PEMBANGUNAN GEDUNG DARI NOL

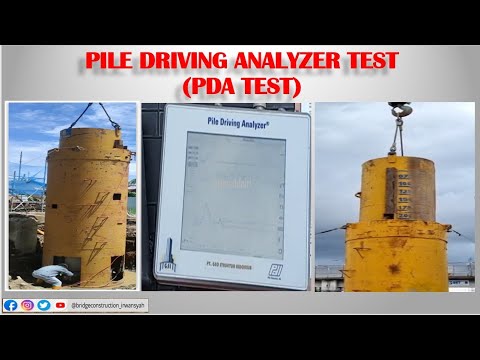

Pekerjaan PDA Tes Pada Borepile by IRWANSYAH

Pile Foundation and It's Types | Bridge Engineering | Lec - 05

How to RWD in Forza Horizon 5 | Building/Tuning/Driving Tips for Rear Wheel Drive Cars

5.0 / 5 (0 votes)