METODE PELAKSANAAN PONDASI TIANG PANCANG

Summary

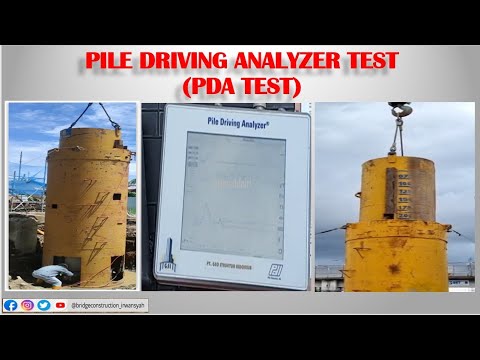

TLDRThis video outlines the detailed process of pile driving, including preparation, tool selection, and various methods involved. It covers the essential steps like site preparation, equipment choice, transportation, and storage of piles. The video also explains the different types of pile hammers, their benefits, and challenges. Techniques for driving piles at an angle, using water sprays for penetration, and connecting piles are discussed. Further, the video highlights essential testing methods like static and dynamic load testing and the importance of accurate monitoring to ensure optimal pile foundation performance.

Takeaways

- 😀 Site preparation is crucial for pile driving, ensuring soil conditions and stable placement of equipment.

- 😀 The pile driving process begins with choosing appropriate equipment based on the soil type and pile specifications.

- 😀 Piles should be transported and stored in an organized manner, grouped by type, diameter, and manufacturing date.

- 😀 Marking each pile with depth indicators is essential for monitoring the pile installation process.

- 😀 Pile hammers come in different types (drop hammer, diesel hammer, hydraulic hammer, vibratory drivers), each suited to different soil and pile conditions.

- 😀 Drop hammers are cost-effective and simple to operate but can be slow and cause vibrations.

- 😀 Diesel hammers are mobile and efficient but can cause noise and pollution, making them suitable for specific applications.

- 😀 Hydraulic hammers offer high efficiency, minimal noise, and are ideal for challenging soil conditions.

- 😀 Inclined pile installation (positive or negative) is used to enhance lateral support in specific conditions.

- 😀 Pile testing, including static load tests and dynamic load tests, is critical for ensuring the pile's capacity and stability under load.

Q & A

What is the first step in the piling installation process?

-The first step in the piling installation process is to prepare the piling location, which includes assessing the soil condition and ensuring the equipment can be placed in a way that it can support the heavy load.

Why is soil investigation important before piling work?

-Soil investigation is important because it helps determine the type of piling equipment required and ensures that the piles can penetrate to the required depth without causing damage to the structure.

How should piles be transported and stored on-site?

-Piles should be transported to the site in a manner that ensures they meet material strength requirements. They should be stored in a pyramid-like arrangement with wooden supports, grouped by type, diameter, and dimensions.

What role does marking and cushioning play in the pile driving process?

-Marking is used to indicate the depth and positioning of each pile, while cushioning (such as a top cap or cushion) is placed at the top of the pile to absorb impact and protect the pile from damage during driving.

What types of pile drivers are commonly used in the field?

-Common types of pile drivers include drop hammers, diesel hammers, hydraulic hammers, and vibratory drivers. Each type is suited to different soil conditions and pile types.

What are the advantages of using a drop hammer?

-Drop hammers are cost-effective, easy to operate, and have a simple mechanism. They are also flexible in energy output, depending on the height from which the hammer is dropped.

What are some limitations of using a diesel hammer?

-Diesel hammers are limited by their inability to operate effectively on soft soils and they can generate significant noise and air pollution. Additionally, determining the exact energy per stroke can be difficult.

How does a hydraulic hammer differ from other types of pile drivers?

-Hydraulic hammers are more efficient in transferring energy to the pile, with a higher energy transfer rate. They are also more suitable for constrained environments and produce less noise and vibration compared to other hammers.

What is the purpose of using water spraying during pile driving?

-Water spraying helps to penetrate the pile into the ground more effectively, especially in sandy soils. However, it is not as effective for other soil types, such as gravel, silt, or clay.

What methods are used to test the bearing capacity of piles?

-Methods for testing bearing capacity include static load tests, dynamic load tests (PDA tests), and pile driving analysis. These tests help assess the pile's ability to support the required loads based on its behavior under various conditions.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pile Driving Equipment Selection and Penetration Limitations | Pile Driving Series #2

Pekerjaan PDA Tes Pada Borepile by IRWANSYAH

OH BEGINI!! PROSES PEMBANGUNAN GEDUNG DARI NOL

Pile Foundation and It's Types | Bridge Engineering | Lec - 05

Animasi Metode Pelaksanaan Jembatan Beton dan Rangka Baja

AUM PTSDL

5.0 / 5 (0 votes)