Just in Time Production Explained | Toyota, Dell and Walmart Examples

Summary

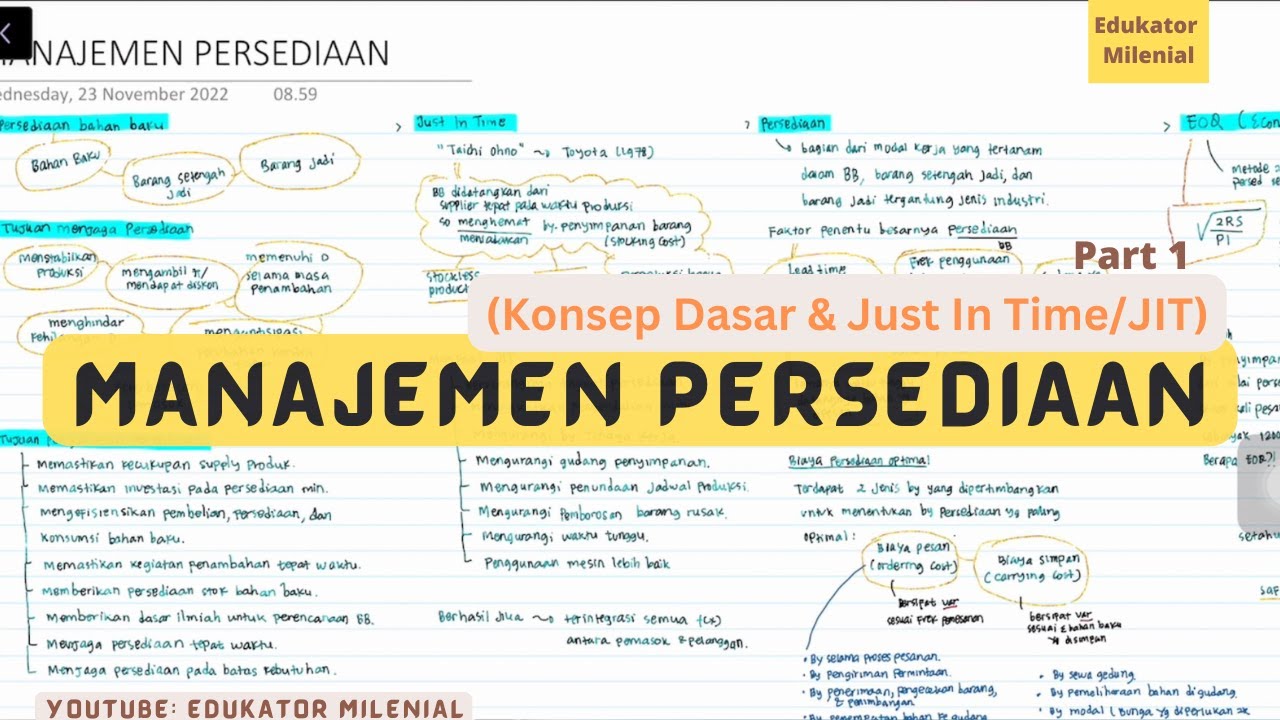

TLDRJust-in-Time (JIT) production is a management strategy that minimizes waste and maximizes efficiency by producing goods or acquiring inventory precisely when needed. It aligns production with customer demand, reducing storage and excess stock. JIT requires meticulous planning and coordination across the supply chain. Benefits include cost reduction, increased productivity, and swift response to market changes. However, it also poses risks such as supply chain disruptions and potential loss of economies of scale. Companies like Toyota, Dell, and Walmart have successfully implemented JIT, emphasizing supplier relationships, demand forecasting, and efficient operations.

Takeaways

- 🔧 Just-in-Time (JIT) production is a management approach that focuses on minimizing waste and maximizing efficiency by producing goods or acquiring inventory precisely when needed.

- 📉 JIT production aims to reduce unnecessary storage and excess stock, which can help businesses save capital that would otherwise be tied up in inventory.

- 🚀 It increases overall productivity by eliminating bottlenecks and reducing waiting time, without compromising product quality.

- 🔄 JIT allows for a swift response to changes in customer demand, market trends, and technological advancements, ensuring the right products are delivered at the right time.

- 🔍 Emphasizing quality control at each production stage helps prevent defects and reduce rework, leading to consistent high-quality products.

- 🤝 Maintaining strong relationships with suppliers is crucial for JIT, as it relies on a steady flow of materials and components to avoid production delays.

- 📈 Accurate demand forecasting is key for aligning production schedules with customer requirements, which can be improved by leveraging historical data and market trends.

- 🛠️ Well-organized production systems and standardized work procedures are necessary for maximizing efficiency and minimizing waste in JIT production.

- ⚠️ JIT production's reliance on timely deliveries means any disruption in the supply chain can lead to severe consequences, such as reduced productivity and customer dissatisfaction.

- 🏢 Companies like Toyota, Dell, and Walmart have successfully implemented JIT production, showcasing its potential for streamlining operations, reducing costs, and improving customer satisfaction.

Q & A

What is the primary goal of Just-In-Time (JIT) production?

-The primary goal of JIT production is to minimize waste and maximize efficiency by producing goods or acquiring inventory precisely when it is needed, eliminating unnecessary storage and reducing excess stock.

How does JIT production help businesses respond to changes in customer demand?

-JIT production allows businesses to align production with actual customer demand, enabling them to swiftly respond to changes in market trends and avoid overproduction, thus ensuring the right products are delivered at the right time.

What are some advantages of implementing JIT production?

-JIT production offers advantages such as significant cost reduction in storage and inventory, increased overall productivity, higher output levels without sacrificing quality, and the ability to maintain high-quality products through integrated quality checks.

What are the key factors for successful JIT production implementation?

-Key factors for successful JIT production implementation include maintaining strong relationships with suppliers, accurate demand forecasting, well-organized production systems, optimized workflow, and standardized work procedures.

How does JIT production affect a company's supply chain?

-JIT production requires meticulous planning and robust coordination across the entire supply chain. It necessitates close collaboration and clear communication with suppliers to ensure timely delivery of materials and components.

What are some potential drawbacks of JIT production?

-Potential drawbacks of JIT production include reliance on timely deliveries, which can lead to production delays if the supply chain is disrupted, reduced room for error due to lean inventory, and potential loss of economies of scale due to smaller batch purchasing.

Why is quality control important in JIT production?

-Quality control is important in JIT production because it helps prevent defects, reduce rework, and ensure consistent delivery of high-quality products. It integrates quality checks into the production process, which is crucial for maintaining efficiency and customer satisfaction.

How does Toyota's implementation of JIT production differ from traditional methods?

-Toyota's implementation of JIT production, known as the Toyota Production System, focuses on reducing waste, continuous improvement, and employee empowerment. It emphasizes 'pull production' where each stage only produces what is needed by the next, thus eliminating overproduction and reducing inventory levels.

What is Dell's approach to JIT production in its supply chain?

-Dell's JIT approach involves a build-to-order model where computers are assembled based on customer specifications, minimizing finished goods inventory and reducing the risk of product obsolescence. It collaborates closely with suppliers and uses advanced information systems for efficient supply chain management.

How does Walmart utilize JIT principles in its operations?

-Walmart uses JIT principles by maintaining a continuous flow of inventory and timely replenishment of stock through close collaboration with suppliers. It employs a cross-docking distribution system to minimize inventory holding time and costs, optimizing supply chain efficiency.

Why might JIT production not be suitable for certain businesses?

-JIT production may not be suitable for businesses with highly unpredictable or seasonal demand patterns because it requires accurate demand forecasting and a steady supply chain, which can be challenging to maintain in such fluctuating environments.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

O QUE É JUST IN TIME (Vantagens e Desvantagens)

Manajemen Persediaan (Just In Time - JIT)

Just In Time JIT Definition Investopedia

What is Just-in-Time (JIT) Inventory Management?

[PRESENTASI] TEKNIK PERSEDIAAN METODE JIT (JUST IN TIME) DAN EOQ (ECONOMIC ORDER QUANTITY)

Just In Time - How Toyota, McDonalds and Apple Use Just In Time - With Examples

5.0 / 5 (0 votes)