Just In Time JIT Definition Investopedia

Summary

TLDRJust-in-time (JIT) is a system that ensures goods and materials arrive only when needed, minimizing inventory and maximizing available cash flow. For retailers, JIT requires precise demand forecasting to avoid overstock or empty shelves, while manufacturers rely on it to keep production running smoothly. Key to JIT is the Kanban system, which tracks production stages and signals when additional parts or products are required. This system improves efficiency and quality. JIT is supported by advanced electronic inventory systems that allow businesses to respond quickly to low stock, ensuring smooth operations even with fluctuating demand.

Takeaways

- 😀 Just In Time (JIT) is a system of supplying goods precisely when they are needed, minimizing inventory costs.

- 😀 For retailers, JIT ensures goods arrive just before they hit the shelves for customer purchase.

- 😀 In manufacturing, JIT means parts and raw materials arrive just in time for the final product assembly.

- 😀 A key benefit of JIT is that it allows companies to keep less inventory on hand, freeing up cash and credit for other uses.

- 😀 JIT requires continuous and precise demand monitoring, often using Kanban signals to track when products or parts are needed.

- 😀 Kanban signals facilitate efficiency and quality improvements, supporting the continuous objectives of JIT.

- 😀 Overestimating demand in JIT leads to bloated inventories and markdowns, reducing profits.

- 😀 Underestimating demand results in empty shelves and lost sales for retailers, and production halts for manufacturers due to material shortages.

- 😀 JIT is supported by electronic inventory systems that help businesses monitor stock levels and respond quickly when inventory runs low.

- 😀 Some advanced JIT systems are so precise that production only begins once a customer makes a purchase.

- 😀 Before JIT systems, businesses had to maintain higher inventory levels to account for potential spikes in demand.

Q & A

What is Just In Time (JIT) inventory management?

-Just In Time (JIT) is a system of supplying goods as close as possible to when they are actually needed. For retailers, this means goods arrive just before hitting the shelves for customer purchase, and for manufacturers, parts and raw materials arrive just before they are added to the final product.

How does JIT help businesses manage their finances?

-By keeping less inventory on hand, businesses free up cash and credit for other uses. This allows companies to use their available resources more effectively, avoiding the costs associated with excess inventory.

What role does Kanban play in JIT systems?

-Kanban is used in JIT systems to monitor demand and facilitate communication between different points of production. It uses signals to alert when the next part or product is needed, ensuring that inventory levels remain optimized.

Why is accurate demand forecasting important in JIT systems?

-Accurate demand forecasting is crucial because overestimating demand can lead to bloated inventories and markdowns, while underestimating demand can result in empty shelves and lost sales.

What is the primary challenge for manufacturers in a JIT system?

-The main challenge for manufacturers in a JIT system is underestimation of demand, which can lead to a lack of necessary materials. This results in halted production, making it impossible to deliver products as promised.

How do electronic inventory systems support JIT management?

-Electronic inventory systems allow businesses to monitor their inventory levels more effectively and respond quickly when inventory gets low. This automation enhances the efficiency and accuracy of the JIT process.

How advanced can some JIT systems be?

-Some JIT systems are so advanced that a product is not even manufactured until a consumer buys it, meaning there is no excess inventory or waste.

What risks did businesses face before JIT systems were implemented?

-Before JIT systems, businesses had to maintain higher inventories to prepare for unanticipated spikes in demand. This resulted in higher costs and less efficient use of resources.

What happens when a retailer underestimates demand in a JIT system?

-Underestimating demand in a JIT system leads to empty shelves, resulting in lost sales and potential damage to customer satisfaction.

How does JIT improve efficiency and quality?

-JIT improves efficiency by streamlining production processes and reducing waste. It also improves quality by ensuring that only necessary materials are used, reducing the chances of defects associated with excess stock.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Just In Time - How Toyota, McDonalds and Apple Use Just In Time - With Examples

What is Inventory Control? Explained in 9 minutes

O QUE É JUST IN TIME (Vantagens e Desvantagens)

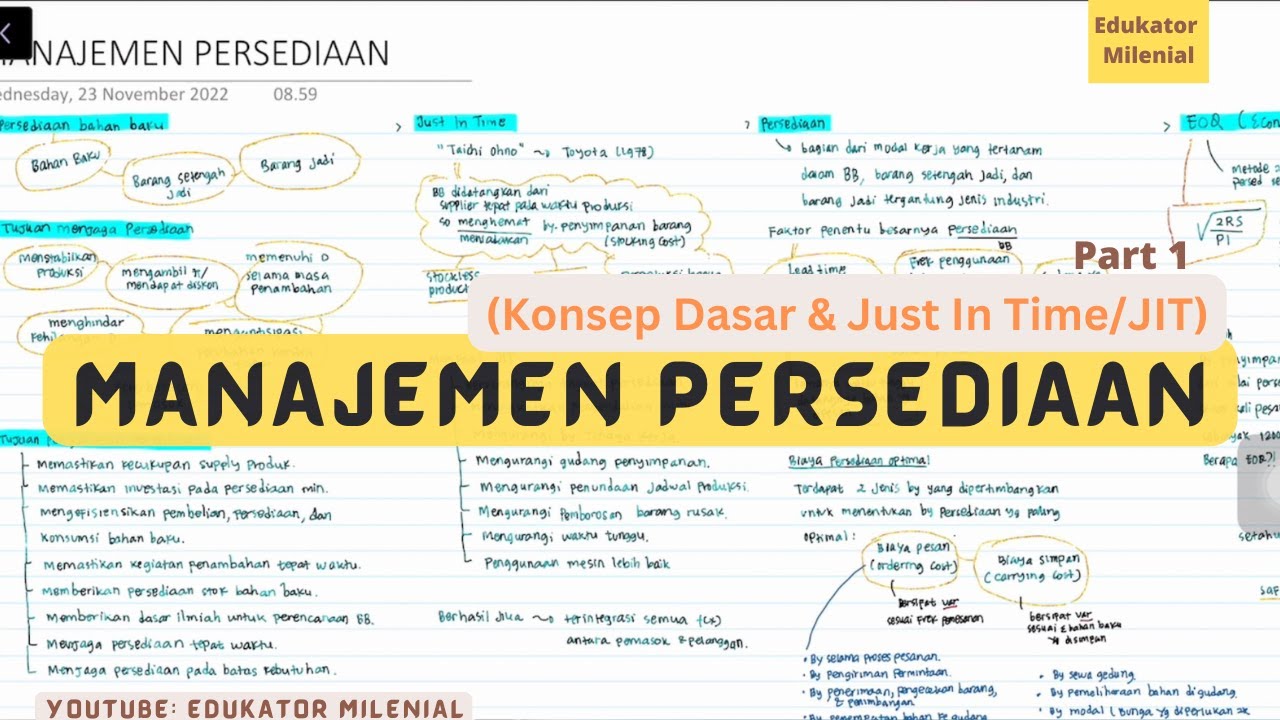

Manajemen Persediaan (Just In Time - JIT)

[PRESENTASI] TEKNIK PERSEDIAAN METODE JIT (JUST IN TIME) DAN EOQ (ECONOMIC ORDER QUANTITY)

What is Just-in-Time (JIT) Inventory Management?

5.0 / 5 (0 votes)