Experiments with the Bubble Model of Metal Structure 1952 - Sir Lawrence Bragg, W.M Lomer, J.F. Nye

Summary

TLDRThis educational video script explores the crystalline structure of metals, using aluminum as an example. It explains how atoms are arranged in regular patterns, often revealed through etching with acid. The script introduces a model using spheres to represent atoms, and a soap bubble raft to simulate crystal formation and deformation. It delves into the concept of dislocations within crystals, their movement, and how they contribute to plastic deformation. The script also discusses the role of dislocations in restoring order in metals and the limitations of the bubble model in representing the three-dimensional structure of metals.

Takeaways

- 🔬 Metals like aluminium have atoms arranged in regular patterns, forming a crystalline structure that can be revealed by etching with acid.

- 🔵 The close packing of atoms in metals is often represented by models such as spheres or table tennis balls, illustrating the uniform forces between them.

- 💭 Bubbles in a soap solution can mimic the behavior of atoms in a metal, showing how they interact due to surface tension and internal pressure.

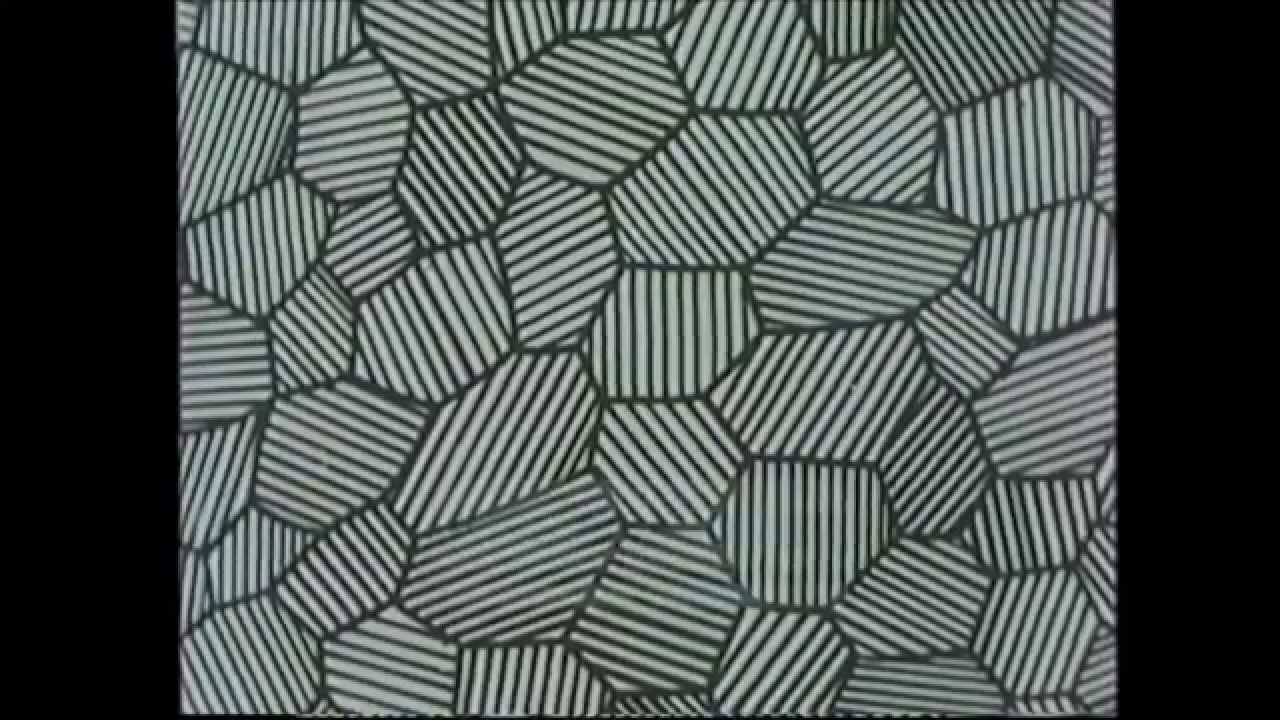

- 🔲 The crystalline pattern in metals can be visualized through the formation of a crystalline raft of bubbles, which aligns in a regular, three-dimensional pattern.

- 🔄 When a metal rod is deformed, it can return to its original shape elastically, but excessive deformation leads to permanent changes, analogous to the movement of bubbles in the model.

- 📏 Dislocations in a metal's crystal structure are like defects that can move and cause plastic deformation; they can be visualized in the bubble model as dark lines moving in specific directions.

- 🔄 The movement of dislocations can alter the shape of a crystal, with the strain required for their movement being less than if the entire atomic row shifted at once.

- 🔍 The Burgers vector is used to quantify dislocations, defining the magnitude and direction of the displacement in a crystal lattice.

- 🔗 Dislocations can interact with each other, sometimes canceling out or combining to form new dislocations, which can be observed in the bubble model.

- 🔧 The presence of impurities or defects can significantly affect dislocation movement, acting as barriers or points of interaction within the crystal structure.

- 🔄 The restoration of order in a distorted metal crystal involves the movement and combination of dislocations, which can be accelerated by external forces, as demonstrated in the bubble model.

Q & A

What is the essential feature of a crystal?

-The essential feature of a crystal is that its atoms are arranged in regular patterns.

How can the regular patterns of atoms in a metal be revealed?

-The regular patterns of atoms in a metal can be revealed by etching it with an acid, which forms pits that reflect light and show the crystal structure.

What is the characteristic form of the regular pattern of atoms in a metal?

-The characteristic form of the regular pattern of atoms in a metal is generally one of the close packing models.

How does the model made of spheres (like table tennis balls) relate to metal atoms?

-The model made of spheres, such as table tennis balls, demonstrates the close packing of atoms in a metal, where small bubbles floating on a solution experience forces similar to those between metal atoms.

What is the purpose of the bubble model in understanding metal crystals?

-The bubble model serves as a visual representation to understand the crystalline structure of metals, where bubbles form a crystalline raft that mimics the regular pattern of atoms in a metal.

How does the bubble model demonstrate the concept of crystal boundaries?

-The bubble model demonstrates crystal boundaries by showing how distinct patterns of bubbles meet at certain points, similar to how different crystal patterns meet in a metal.

What is the significance of dislocations in the context of metal deformation?

-Dislocations are significant in metal deformation because they represent the atomic-scale movement that leads to plastic deformation. They allow the closely packed planes of atoms to slip over each other, causing the metal to change shape.

What is a Burgers vector and how does it relate to dislocations?

-A Burgers vector is a vector that defines the magnitude and direction of the displacement associated with a dislocation. It is used to quantify the movement of dislocations within a crystal lattice.

How can dislocations be created in a crystal?

-Dislocations can be created in a crystal through rapid crystallization, which may leave them as growth accidents, or from groups of vacancies where atoms are missing, leading to the formation of dislocation pairs.

What role do impurities play in the movement of dislocations?

-Impurities, represented by bubbles of different sizes in the model, can interfere with the movement of dislocations, acting as centers of strain and significantly affecting the metal's plastic deformation.

How does the bubble model illustrate the process of plastic deformation and recovery in metals?

-The bubble model illustrates plastic deformation by showing dislocations moving and combining under stress, and recovery by demonstrating how dislocations tidy up areas of strain and create nearly perfect crystal regions, which then adjust their boundaries to reduce their energy.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Ikatan Kimia Animasi | Ikatan Logam | Ikatan pada Cu (Tembaga)

Aula 10 – Estruturas Cristalinas Cúbicas de Face Centrada, Corpo Centrado e Hexagonal Compacta.

Legame Ionico - Legami Chimici | Lezioni di Chimica

Crystallinity in Polymers

GCSE Chemistry Revision "Ionic Bonding 1: Ionic Bonding between Group 1 and Group 7"

Properties and Grain Structure

5.0 / 5 (0 votes)