Understanding electric motor Windings!

Summary

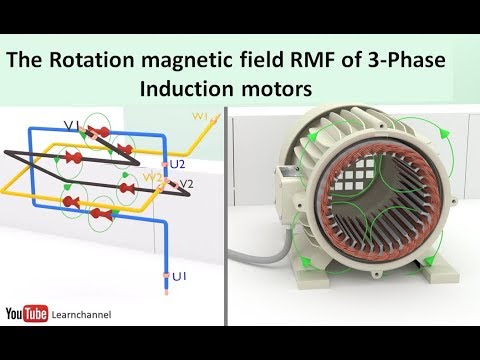

TLDRThis video script explores the automated process of fabricating three-phase windings, essential for generating a rotating magnetic field (RMF) in electric motors. It explains the principles behind creating a smooth, undistorted RMF, credits Nikola Tesla for the phase shift concept, and demonstrates how varying the number of slots in the winding design impacts the RMF's uniformity and speed. The script concludes with the application of these windings in everyday appliances, highlighting the importance of engineering in motor performance.

Takeaways

- 🔧 The video script describes the fully automatic process of fabricating three-phase windings in factories, which are crucial for creating a rotating magnetic field (RMF) in electric motors.

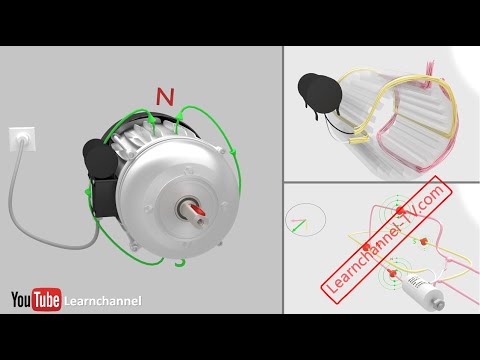

- 🌀 The RMF is generated by the three-phase windings taking in electric current, and it is responsible for the motor's rotation.

- 🤔 The script poses a question about how a stationary winding can create a rotating magnetic field, which is then explained through the principles of electrical engineering.

- 🛠️ The design of the windings is the result of years of effort, including design iterations, analysis, and the application of fundamental electrical engineering principles.

- 🧲 The script outlines the qualities of a good RMF, which should have a smooth shape, not distort during rotation, and have perfectly radial central flux lines.

- 🔄 Nikola Tesla's concept of phase shift is introduced as the key to creating a rotating magnetic field with stationary coils.

- 📈 The script explains the development of a winding design that generates a rotating magnetic field, starting with a simple coil and progressing to a six-slot design.

- 🔌 The use of multiple turns of thin cable in the industry increases the magnetic flux strength, with each turn insulated to prevent short circuits.

- 💻 The quality of the RMF is checked using FEA (Finite Element Analysis) results from em Works 2D software by SolidWorks.

- 🔄 The script discusses modifications to the winding design to achieve a more uniform RMF, including increasing the number of conductors and adjusting the coil connections.

- 🔗 The difference in speed and torque between two-pole and four-pole RMFs is highlighted, with the two-pole RMF rotating faster but providing less torque.

- 🔄 As the number of poles increases, the relationship between speed and torque remains consistent, with higher pole counts providing more torque but less speed.

- 🛠️ The script concludes with the preference for 24-slot windings for a smoother and more uniform RMF, and the application of these windings in various motor uses.

Q & A

What is the purpose of three-phase windings in a motor?

-Three-phase windings are designed to take in electric current and create a rotating magnetic field (RMF), which is responsible for the motor's rotation.

How does the rotating magnetic field (RMF) rotate even though the windings are stationary?

-The RMF rotates due to the phase shift concept introduced by Nikola Tesla, which involves keeping the maximum values of the three fields at different instances to avoid fluctuating behavior and create a uniform rotating field.

What are the fundamental qualities of a good RMF?

-A good RMF should have a smooth shape, not get distorted during rotation, and have perfectly radial central flux lines.

Why was the initial design with three coils apart by 120 degrees a failure?

-The initial design failed because all three magnetic fields had their maximum or minimum values at the same instance, causing the resultant field to fluctuate and not rotate smoothly.

Who is credited with the concept of phase shift in electrical engineering, and how does it help in creating a rotating magnetic field?

-Nikola Tesla is credited with the concept of phase shift. It helps in creating a rotating magnetic field by ensuring that the maximum values of the three fields occur at different instances, thus avoiding a fluctuating behavior.

What is the significance of the number of slots in a winding design?

-The number of slots in a winding design affects the uniformity and strength of the RMF. More slots result in a more uniform and constant strength RMF.

How does the number of poles in an RMF affect its speed and torque?

-The number of poles influences the speed and torque of the RMF. A two-pole RMF rotates at double the speed of a four-pole RMF but provides less torque, while a four-pole RMF provides more torque but rotates at a slower speed.

What is the role of FEA results in checking the quality of the RMF?

-FEA (Finite Element Analysis) results, produced with software like SolidWorks, are used to visualize and analyze the shape, uniformity, and consistency of the RMF during rotation, ensuring it meets the design criteria.

How are the windings supported inside the motor?

-The windings are generally supported inside an iron structure, which also carries the magnetic flux lines, enhancing the magnetic field strength.

What is the process of winding the coils in the industry?

-In the industry, the coils are wound on a Pharma, with two to three sets wound on each side. The Pharma loaded with coil groups is then inserted into the stator core by hydraulic pressure, followed by precise connections and testing before operation.

Why are more complex windings preferred for a smoother experience of the RMF?

-More complex windings, such as a 24 slots design, provide a smoother and more uniform RMF with constant strength throughout its rotation, which is preferred for better performance in various applications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Memahami Lilitan motor listrik!

Induction Motor animation I: The Rotating Magnetic Field RMF

Memahami RMF | Daya pengemudian dibalik semua mesin AC

Rotating Magnetic Field (How it produce) Unit 4 Electrical Machines (1st year Engineering) EEE (BEE)

Single Phase Induction Motor (Capacitor Induction Motor or AC Motor) explained

motore asincrono trifase - 01 - principio di funzionamento

5.0 / 5 (0 votes)