Section through a Brick Veneer, Slab on ground Building Part 1

Summary

TLDRThis video script offers a detailed walkthrough of constructing a brick veneer slab on ground, a common method in Sydney. It begins with site leveling and concrete slab formation, incorporating Waffle Pod for strength and less concrete usage. The process continues with reinforcement, slab pouring, and formwork removal. The script then describes wall construction, including bottom plates, studs, noggins, and lintels, followed by fascia and roofing. The focus is on the importance of the first tile's angle and preventing moisture issues with anti-ponding boards. The video promises to cover brickwork and interior fitting in the next installment.

Takeaways

- 🏗️ The video provides a step-by-step guide for building a brick veneer slab on ground.

- 🌍 This method is commonly used in Sydney, particularly for project homes.

- 🛠️ The process begins with leveling the site using a grader, bulldozer, and laser level.

- 🔨 Formwork is set up to pour the concrete slab, including forming a recess for the brickwork.

- 🧱 The Waffle Pod slab method is often used, involving foam blocks to create voids and reduce concrete usage.

- 🪨 Alternatively, compacted hardcore fill with a layer of blinding sand can be used before the membrane.

- 📄 A 200 micron polyethylene membrane (Forticon) is placed to prevent punctures and ensure smoothness.

- 🔗 Reinforcement, including trench mesh and concrete slab mesh, is installed as per structural engineer designs.

- 🧱 Once reinforcement is inspected and approved, the concrete slab is poured and cured for about a week.

- 🏠 The video covers the subsequent steps of constructing walls, installing windows and doors, and building the roof structure.

Q & A

What is the most common method of building a house in Sydney as described in the script?

-The most common method of building a house in Sydney is through a brick veneer slab on ground, which relies on being built on a level block of ground.

Why is the site leveled before building the house?

-The site is leveled to ensure a stable and even foundation for the house, using a grader, bulldozer, and laser level to achieve a perfectly level surface.

What is a Waffle Pod slab and how does it contribute to the construction process?

-A Waffle Pod slab is a roughly one-meter by one-meter square block of foam that creates a void under the slab, reducing the amount of concrete used while still providing strength through the pattern that creates beams in between the slab.

What is the purpose of the membrane placed directly on the ground during the construction of the slab?

-The membrane, commonly called Forticon, is placed to prevent moisture from seeping into the ground and to maintain a smooth surface, preventing rocks from puncturing holes in the membrane.

Why is compacted hardcore fill used in the construction process?

-Compacted hardcore fill is used to provide a solid base for the slab and to create trenches for beams, ensuring structural integrity and support for the house.

What is the role of the reinforcement in the concrete slab?

-The reinforcement, which includes bar chairs and a cage of Trench mesh, is designed to provide structural strength and stability to the concrete slab, as specified by the structural engineer's plans.

How long does it generally take to strip the formwork after pouring the concrete slab?

-It generally takes about a week for the concrete slab to cure enough to safely strip the formwork.

What are the components of the wall in course in the construction process described?

-The wall in course is made up of a bottom plate, common studs, noggins, a window sill, jamb stud, lintel, and a top plate, with a ribbon plate for the trusses to sit on.

Why is the fascia installed before the roof tiles?

-The fascia is installed first to provide a finished edge for the roof and to support the roof structure, ensuring a solid base for the tiles.

What is the purpose of the Bellcast batten in the roofing process?

-The Bellcast batten is used to kick the first tile, ensuring that the angle of the tile looks consistent and aesthetically pleasing, preventing the first tile from looking flat.

What is the function of the anti-ponding board in the roofing process?

-The anti-ponding board, made of 4.5mm fibro, supports the sarking and prevents it from sagging near the gutter, ensuring that moisture runs off effectively into the gutter.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Formwork to slab on ground

Section through a Brick Veneer, Slab on ground Building Part 2

Les bons gestes en maçonnerie - Briques de parement

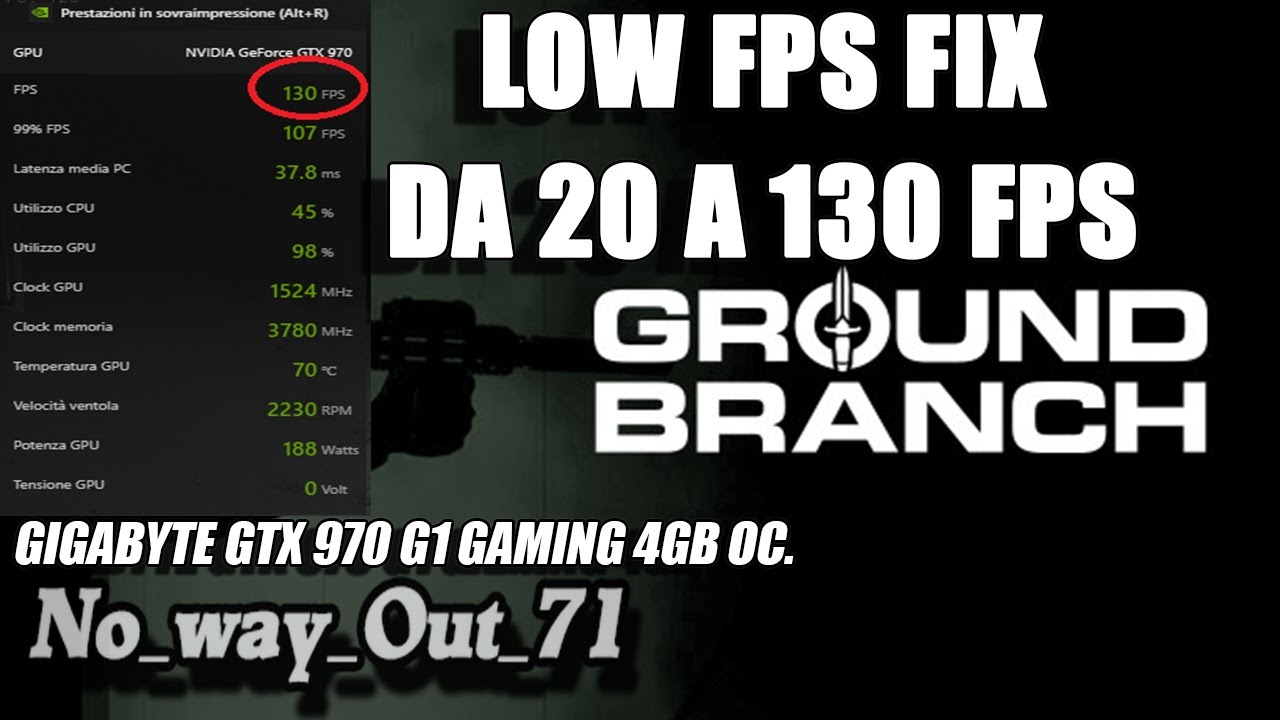

Ground Branch || low FPS Fix - da 20 FPS a 130 FPS

Day-8 | DevOps Zero to Hero | Shell Scripting Project Used In Real Time | GitHub API Integration

Precio Unitario de Zapata Corrida

5.0 / 5 (0 votes)