REFRIGERATION SYSTEM| (PART-1)|

Summary

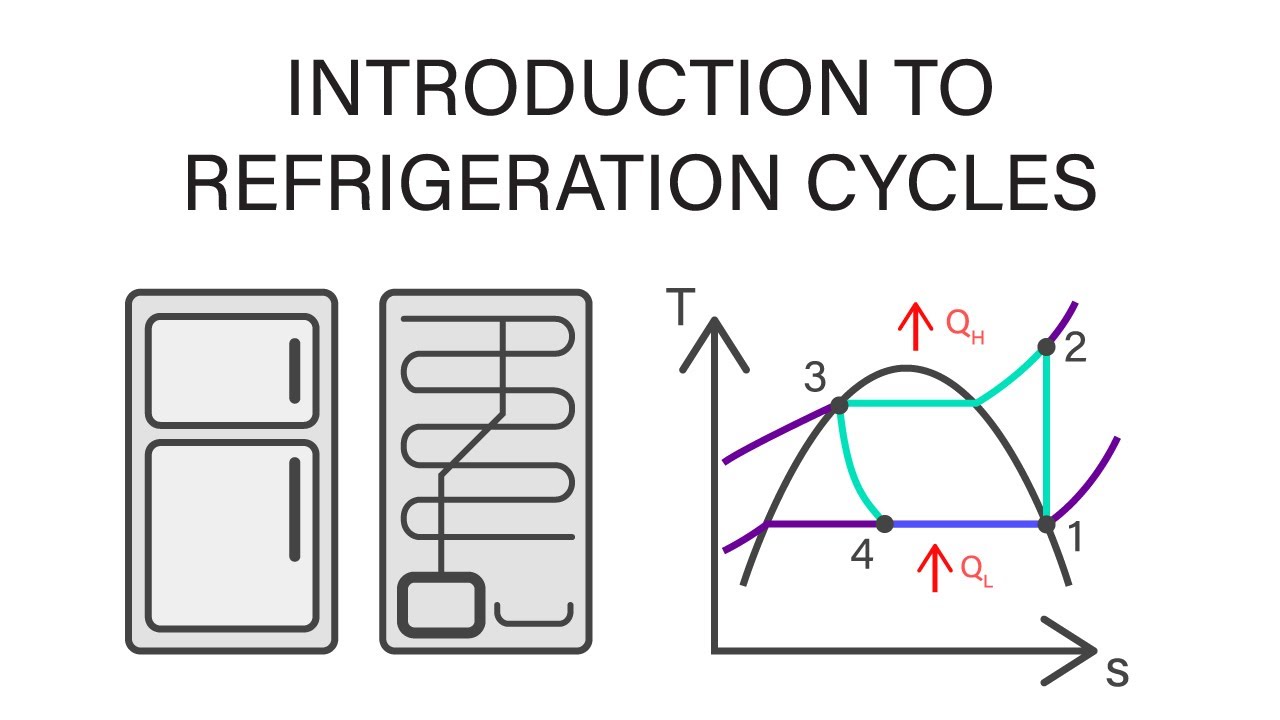

TLDRIn this educational video, narrator Ravi Gupta introduces the fundamental principles of refrigeration systems, focusing on the vapor compression cycle. He outlines the four main components: compressor, condenser, expansion valve, and evaporator, explaining their roles in the refrigeration process. The script delves into the system's pressure and temperature dynamics, safety devices, and the heat transfer process, all crucial for understanding the efficiency and performance of refrigeration systems.

Takeaways

- 🔧 The refrigeration system operates on the vapor compression cycle, which involves a closed loop of components.

- 🔄 The four main components of a refrigeration system are the compressor, condenser, expansion valve, and evaporator.

- 📈 The compressor's role is to raise the saturation temperature of the refrigerant, preparing it for cooling in the condenser.

- 🌡 After compression, the refrigerant's temperature increases, and it is then cooled in the condenser, changing from gas to liquid form under high pressure.

- 💧 The expansion valve is a pressure controller that reduces the pressure from high to low, facilitating the transition from liquid to gas form.

- 🔄 The system can be divided into high-pressure and low-pressure sections, with the evaporator and compressor on the low-pressure side and the condenser on the high-pressure side.

- 🛡️ Safety devices such as the master solenoid valve and dryer are integral to the system to prevent faults and maintain proper operation.

- 🌡️ The thermostatic expansion valve plays a crucial role in controlling the pressure and temperature of the refrigerant as it enters the evaporator.

- 🌡️ The evaporator extracts heat from the surroundings, cooling the area and causing the refrigerant to boil off and convert from liquid to gas.

- 🔄 The defrost element helps maintain efficient heat transfer by periodically defrosting the evaporator coil to prevent ice buildup.

- 📊 Understanding the pressure-enthalpy diagram is essential for visualizing the heat transfer and work processes within the refrigeration cycle.

Q & A

What is the basic principle that refrigeration systems work on?

-Refrigeration systems work on the principle of the vapor compression cycle.

What are the four basic components of a refrigeration system?

-The four basic components of a refrigeration system are the compressor, condenser, expansion valve, and evaporator.

What is the primary function of a compressor in a refrigeration system?

-The primary function of a compressor is to raise the saturation temperature of the refrigerant so that it can be cooled by the condenser.

How does the condenser cool the refrigerant?

-The condenser cools the refrigerant by either using sea water or fresh water, changing its vapor form into a liquid form.

What role does the expansion valve play in the refrigeration system?

-The expansion valve acts as a pressure controller, converting the high-pressure refrigerant into a low-pressure refrigerant, facilitating the transition from liquid to gas form.

How does the refrigerant change from liquid to gas in the evaporator?

-As the refrigerant enters the evaporator, it extracts heat from the environment, boiling off and converting from a low-pressure liquid to a gas.

What is the purpose of the high-pressure cutout in a refrigeration system?

-The high-pressure cutout is a safety device that prevents the system from pressurizing excessively by cutting off the flow if the valve before the condenser is set.

What is the function of a dryer in the refrigeration system?

-The dryer is used to eliminate any gas, moisture, or oil particles that might be carried over from the compressor, ensuring clean refrigerant flow.

How does a thermostatic expansion valve control the refrigerant flow?

-A thermostatic expansion valve monitors the conditions inside the evaporator and adjusts the opening to control the flow of refrigerant based on the sensed temperature.

What is the purpose of the defrost element in the evaporator?

-The defrost element is provided to periodically defrost the evaporator coil, preventing the unwanted accumulation of ice and ensuring efficient heat transfer.

How is the coefficient of performance (COP) of a refrigeration system determined?

-The COP is determined by the ratio of the heat energy received (from the environment) to the heat energy equivalent of the work done (compression work plus heat rejected in the condenser).

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Mechanical Engineering Thermodynamics - Lec 23, pt 1 of 4: Introduction to Refrigeration Cycles

Analisis Siklus Refrigerasi Kompresi Uap Ideal

Refrigerator working - The Basics

Refrigerasi02

Termodinamika Kelas XI IPA

Ciclo Básico de Refrigeração Parte 1 Curso de refrigeração domiciliar, comercial, climatização

5.0 / 5 (0 votes)