Inside a Washing Machine Motor: Explanation, Pinout, Teardown AND Experiments

Summary

TLDRThis video explores the inner workings of a washing machine motor, demonstrating how to identify pinouts, power it with AC or DC, and differentiate it from a standard DC motor. The host also discusses motor speed control, field coils, and potential applications in robotics and electric vehicles.

Takeaways

- 🔧 The video demonstrates a teardown of a Zeman's washing machine motor to salvage an electric motor and fitting belt.

- 🔍 The presenter explores the motor's internals to understand its pinout, enabling repurposing for various projects.

- 🔌 The motor's pinout is crucial for its functionality, and the video provides a detailed guide on identifying and utilizing it.

- 🏗️ The motor has a tacho coil for speed regulation, which is an important aspect of its operation.

- ⚙️ The video explains the differences between universal motors and ordinary DC motors, focusing on their construction and operation.

- 🔥 A safety feature, the thermal switch, is highlighted to protect the motor from overheating.

- 🔄 The video shows how to power the motor using both AC and DC, discussing the implications of each method on motor performance.

- 🔋 The presenter discusses the concept of self-excited motors and how they differ from separately excited DC motors.

- 📉 The importance of controlling motor speed and torque is emphasized, with demonstrations of how to achieve this.

- 🧲 The role of field coils in generating the magnetic field is explained, and their impact on motor speed and torque is demonstrated.

- 🛠️ The video concludes with experiments showing the effects of remnant magnetism in the stator pack and the possibility of using permanent magnets instead of field coils.

Q & A

What was the main purpose of the video?

-The main purpose of the video was to demonstrate how to salvage an electric motor from a washing machine, explore its internal components, and show how to power it with both AC and DC sources.

Why did the presenter choose to examine a Milliband washing machine motor instead of the Zeman's motor?

-The presenter chose to examine a Milliband washing machine motor because it was bulkier, more rugged, and he had a couple of them available for future projects, unlike the Zeman's motor which was precious due to its own transmission.

What is a universal motor and how does it differ from an ordinary DC motor?

-A universal motor is a type of electric motor that can be powered by both AC and DC sources. It differs from an ordinary DC motor, which typically uses permanent magnets, by having field coils or field windings that generate the magnetic field when powered by AC or DC.

What is the significance of the tacho coil in the motor?

-The tacho coil is used in conjunction with a small permanent magnet and a coil to read out the motor speed and control it. It is an important component for motor regulation.

What safety feature is the thermal switch in the motor?

-The thermal switch is a safety feature that protects the motor from overheating. It is conductive at normal temperatures but switches off when heated, preventing current flow until it cools down.

What does the term 'series wound' mean in the context of motors?

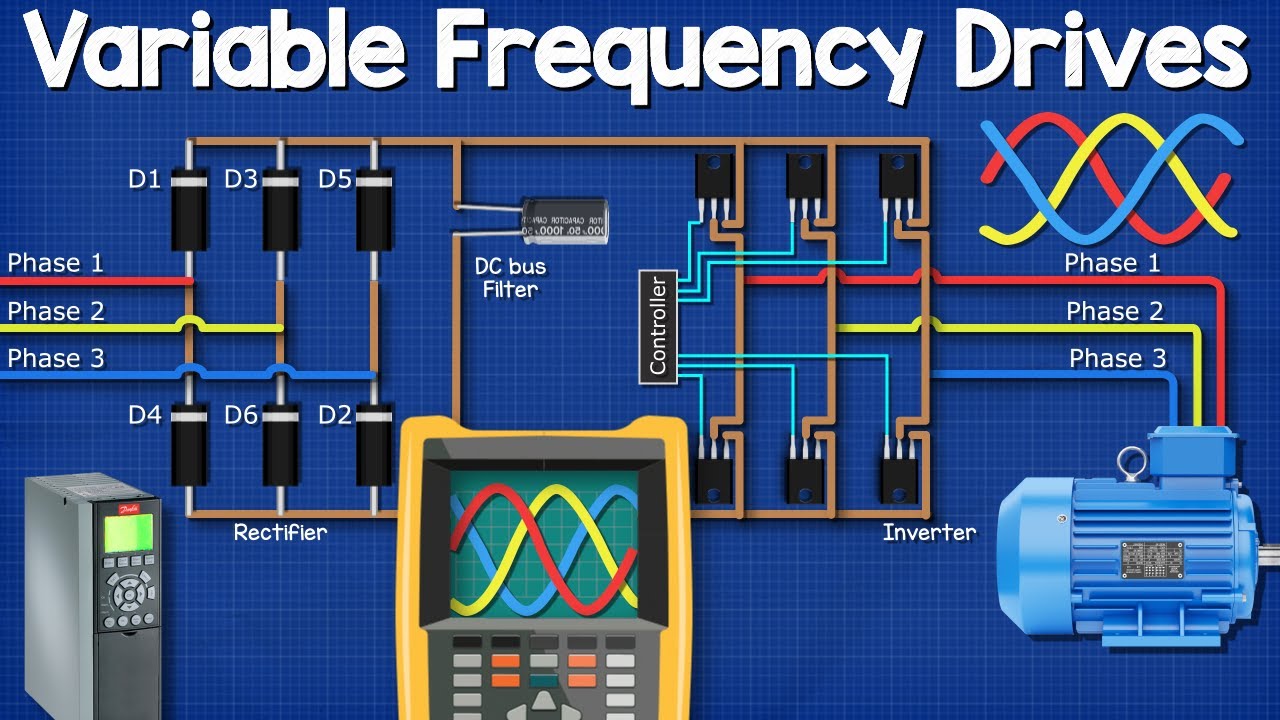

-In the context of motors, 'series wound' refers to a configuration where the field coils and the armature are connected in series, meaning the same current flows through both, affecting the motor's speed and torque.

How can the motor speed and torque be controlled when using a universal motor?

-The motor speed and torque can be controlled by adjusting the voltage across the armature and the current through the field windings. Using independent voltage or current sources for each allows for precise control.

What is a 'self-excited' motor and how does it differ from a 'separately excited' DC motor?

-A 'self-excited' motor is one where the field coils and the armature share the same current, meaning the voltage across them is not independent. This differs from a 'separately excited' DC motor, where the armature and field coils are powered by independent sources, allowing for separate control of speed and torque.

Why are iron filings used in the experiment with the motor's stator pack?

-Iron filings are used to visualize the magnetic field lines within the stator pack of the motor. They align themselves along the magnetic field lines, providing a visual representation of the field's structure.

What is the remnant magnetic field and why does it cause the motor to continue rotating even when the field coil current is shut off?

-The remnant magnetic field is the weak magnetic field that remains after the current through the field coils is shut off. It is caused by some magnetic domains in the stator pack retaining their alignment from when the current was flowing. This remnant field can cause the motor to continue rotating, albeit with reduced torque.

How can a universal motor be powered by DC using permanent magnets instead of field coils?

-A universal motor can be powered by DC using permanent magnets by placing them in a stationary position to create a constant magnetic field. The motor's armature can then interact with this field to produce rotation, eliminating the need for field coils.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)