How Robots Use Maths to Move

Summary

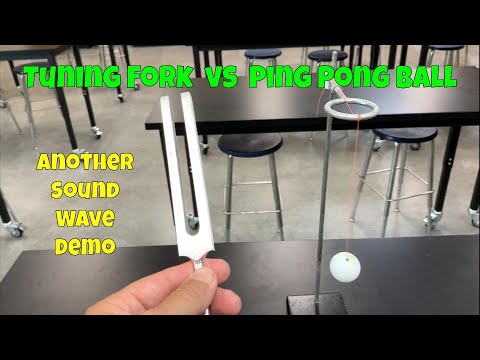

TLDRThis video script details the creation of a simple robot arm project with an inverse kinematic model, designed to move a ping pong ball through a contraption. The project uses basic servos, 3D-printed parts, and an Arduino Uno for control. It demonstrates the arm's ability to move in a straight line in 2D space and includes a gripper for ball manipulation. The script also discusses the use of potentiometers for analog input and the 'ramp' library for smooth motion interpolation. The project is part of a larger 'Great Ball Contraption' and is shared as open-source on GitHub.

Takeaways

- 🤖 The video discusses the application of inverse kinematics in robotics, which is essential for positioning a robot's end effector in a specific location within a known coordinate system.

- 📐 The presenter has used inverse kinematics in robot dog projects to coordinate the feet for movement in three dimensions, allowing for translation and rotation.

- 🔧 The project involves a simple robot arm with a basic inverse kinematic model, which is part of a larger 'Great Ball Contraption' project demonstrating science and engineering concepts.

- 🛠️ The robot's base consists of a sliding axis with V-wheels and a frame for stability, using drop-in T-nuts for easy assembly.

- 🔩 The robot arm uses basic servos with metal brackets for easy mounting, creating a limb with multiple joints that can be controlled via a servo PWM signal.

- 🔄 The arm includes a linear axis for shoulder movement, an elbow joint, and a gripper at the end controlled by another servo, designed to pick up and move ping pong balls.

- 🔋 A 7.4-volt 2-cell LiPo battery powers the servos and a DC motor for the linear axis, managed by an L298 motor driver.

- 📊 The inverse kinematic model for the robot is simple, suitable for an 8-bit Arduino Uno, and involves calculating joint positions based on the desired end effector position.

- 📐 The arm's design uses a triangle with two equal sides, simplifying the math for calculating joint angles using Pythagoras' theorem.

- 📊 The video includes a demonstration of the arm's movement in a straight line controlled by potentiometers, showing the effectiveness of the inverse kinematics model.

- 💻 The project's code and CAD files are open source and available on GitHub for modification and inspiration for other projects.

Q & A

What is the purpose of an inverse kinematic model in robotics?

-An inverse kinematic model in robotics is used to calculate the joint positions required to place the end effector, such as a robot's foot, at a specific point in a known coordinate system.

How does the inverse kinematic model enable a robot to move its feet in a coordinated manner?

-The model allows the robot's feet to move from point A to point B in a straight line by calculating the joint positions at each waypoint between the two positions, enabling coordinated movement in three axes of translation and rotation.

What is the 'Great Ball Contraption' project mentioned in the script?

-The 'Great Ball Contraption' is an ongoing project that involves creating a series of machines to pass ping pong balls from one stage to another, demonstrating various science and engineering concepts.

What materials and components are used for the main base of the robot in the project?

-The main base of the robot consists of a simple sliding axis with V wheels attached to a 3D print using M5 bolts and lock nuts, with the wheels fitted with bearings and spacers for smooth rotation.

How are the servos used in the robot arm project mounted and connected?

-The servos are mounted using metal brackets and connected by screwing them onto 3D prints with self-tapping screws, allowing for easy assembly of the robot arm's multiple joints.

What role does the servo mounted on top of the first servo play in the robot arm?

-The servo mounted on top of the first servo provides an additional mechanical stage to the robot arm, functioning as the shoulder joint, which, along with the elbow joint, allows for a wide range of positions.

What is the function of the gripper's fingers and how are they constructed?

-The gripper's fingers are 3D printed and consist of two parallel plates that are spaced apart and screwed together to grip the ping pong balls. They are actuated by a servo that pulls strings attached to the plates to open and close the gripper's jaw.

What is the computational requirement for the kinematic model of the robot arm?

-The kinematic model for the robot arm is simple enough to be controlled by an 8-bit Arduino Uno, which calculates the necessary joint positions based on the desired end effector position.

How is the linear sliding axis of the robot arm powered and controlled?

-The linear sliding axis is powered by a 7.4-volt 2-cell LiPo battery, which provides sufficient current to operate the servos and the DC motor. The motor is controlled using an L298 motor driver and an encoder for precise movement.

What modifications were made to the robot arm to ensure the gripper does not crush the ping pong balls?

-An elastic band was used to pull the gripper fingers together for gripping the ping pong balls, and the gripper activation servo was adjusted to ensure the fingers move freely and do not apply excessive force.

How does the Arduino ramp library help in making the robot arm's motion smoother?

-The Arduino ramp library allows for interpolation between positions, enabling the servos to move at a controlled speed and reach their target positions smoothly over a specified time period.

What is the final function of the robot arm in the 'Great Ball Contraption' project?

-The robot arm is programmed to move through set motions using the kinematic model to pick up ping pong balls at a sensor-triggered ramp, transport them to the other end, and drop them into the next stage of the contraption.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)