POLYETHYLENE | Pipeline Coatings

Summary

TLDRIn this episode of 'Bite-Sized Corrosion,' Vanessa and Neil delve into the complexities of pipeline coatings, focusing on polyethylene coatings. They discuss the benefits and challenges of these coatings, including their toughness, chemical resistance, and the difficulty of adhesion. The conversation explores various types of polyethylene coatings, such as single-layer, two-layer, and 3-layer polyethylene (3LPE) systems, and touches on issues like cathodic shielding and AC interference. The episode aims to guide new engineers on selecting appropriate coatings for pipeline projects, considering factors like environment, service life, and cost.

Takeaways

- 🌟 The session is part of a series discussing pipeline coatings, starting with polyethylene coatings.

- 🎨 Vanessa Silly Fisher and Neil Webb are the hosts of the series, aiming to shed light on the complexities of pipeline coatings.

- 🔍 Vanessa shares a personal anecdote about the challenges of identifying coatings in the field, highlighting the importance of understanding different types of coatings.

- 🛠️ Polyethylene coatings are prevalent due to their toughness, high electrical resistance, and good chemical resistance, making them suitable for pipelines.

- 📦 The black color of polyethylene coatings is due to carbon black pigment, which is a significant component of the material.

- 🧲 One of the main challenges with polyethylene is its poor adhesion to pipes, as it doesn't stick to other materials easily.

- 🔄 The industry has developed solutions like 'Yellow Jacket' coatings, which use a bitumen-based adhesive to improve adhesion between the polyethylene and the steel pipe.

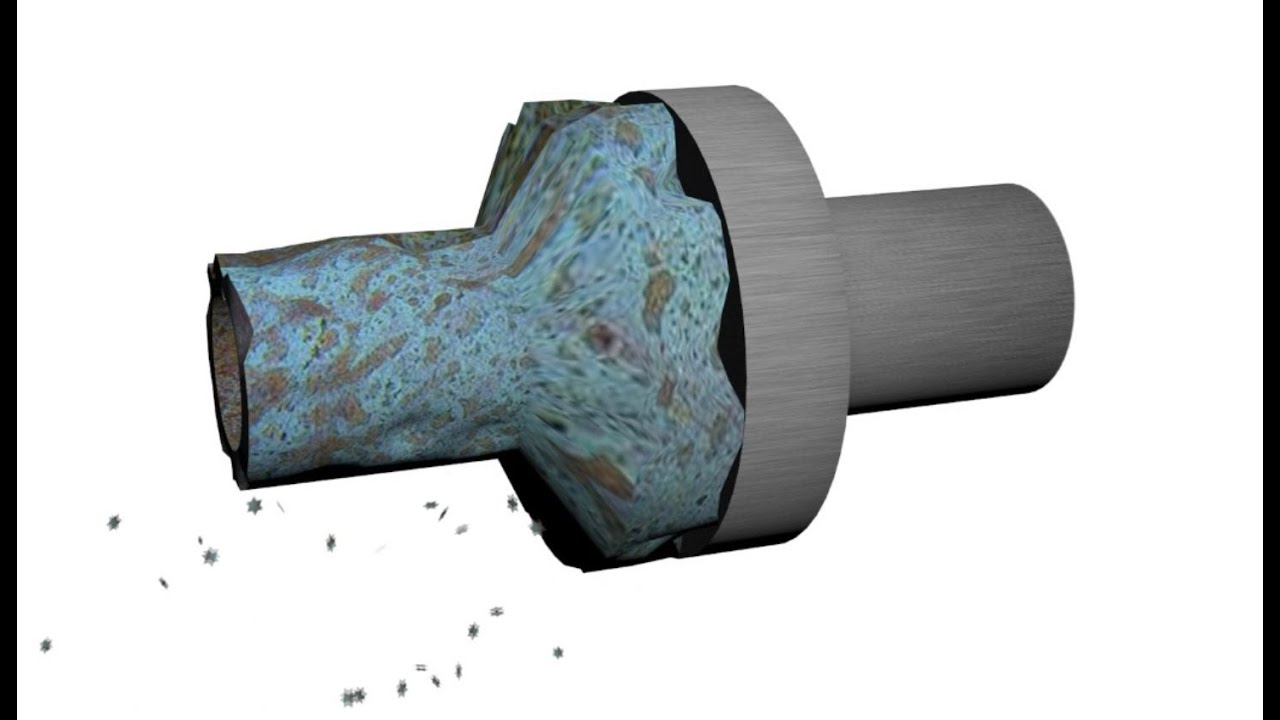

- 📚 The 3-layer polyethylene (3LPE) system combines the corrosion resistance of epoxy with the electrical and mechanical properties of polyethylene, offering a robust coating solution.

- 🛡️ Proper surface preparation is critical for the application of coatings like fusion-bonded epoxy (FBE), which includes cleaning and a phosphoric acid-based wash as a pre-treatment.

- 🔩 Field joints, where pipes are joined together, require special attention with coatings to ensure they are protected to the same standard as the rest of the pipeline.

- 🌐 AC interference is a concern for polyethylene coatings due to their high electrical resistance, which can lead to inductive and capacitive interference issues.

- 🔄 The balance between the electrical insulation properties of the coating and the environmental conditions it will encounter is crucial for effective pipeline protection.

Q & A

What is the main topic of the 'bite-sized corrosion' series for 2022?

-The main topic of the 'bite-sized corrosion' series for 2022 is pipeline coatings, specifically focusing on polyethylene coatings in the first session.

Why is knowledge of the specific coating applied to a pipeline important?

-Knowledge of the specific coating applied to a pipeline is important because it affects pipe laying logistics, backfilling, long-term performance, cathodic protection, and AC mitigation.

What is Vanessa Silly Fisher's initial experience with pipeline coatings?

-Vanessa Silly Fisher's initial experience with pipeline coatings was overwhelming. She was on-site to investigate a corrosion problem that turned out to be a coating issue and found the experience challenging due to her lack of knowledge at the time.

What is the typical color of polyethylene coatings and why?

-Polyethylene coatings are typically black due to the significant pigment content of carbon black in the material.

Why are polyethylene coatings widely used for pipelines?

-Polyethylene coatings are widely used for pipelines because they are tough, have high electrical resistance, excellent chemical resistance, and are not easily damaged.

What is one of the main challenges with applying polyethylene coatings to pipes?

-One of the main challenges with applying polyethylene coatings to pipes is adhesion. Polyethylene is very inert and does not stick to anything else easily, making it difficult to get the coating to adhere to the pipe.

What is the purpose of the 'Yellow Jacket' coating in pipeline applications?

-The 'Yellow Jacket' coating is a polyethylene external extrusion or shrink sleeve that is applied over a layer of bitumen-based adhesive. It provides chemical adhesion between the steel and the polyethylene and offers good chemical and corrosion resistance.

What does 3LPE stand for and what does it combine in terms of pipeline coating properties?

-3LPE stands for 3-Layer Polyethylene. It combines the corrosion-resistant characteristics of epoxy with the electrical resistance, chemical resistance, water impermeability, and mechanical toughness of polyethylene.

What is the significance of the epoxy layer in a 3LPE system?

-The epoxy layer in a 3LPE system is significant because it provides a corrosion-resistant interface between the steel and the polyethylene. It is essential for the system's effectiveness and must be equivalent to a standalone epoxy system.

How does AC interference impact polyethylene coatings?

-AC interference impacts polyethylene coatings because of the high electrical resistance of polyethylene, which provides insulation between the pipe and its environment. This insulation can lead to inductive and capacitive interference, causing high voltages on the pipe due to its insulation from the earth.

What are some alternative polyethylene coating systems mentioned in the script?

-Some alternative polyethylene coating systems mentioned in the script include cold-applied and hot-applied tapes, and heat shrink sleeves, which are based on polyethylene and are used for field joints and mainline wrapping.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)