Centrifugical pumps maintenance

Summary

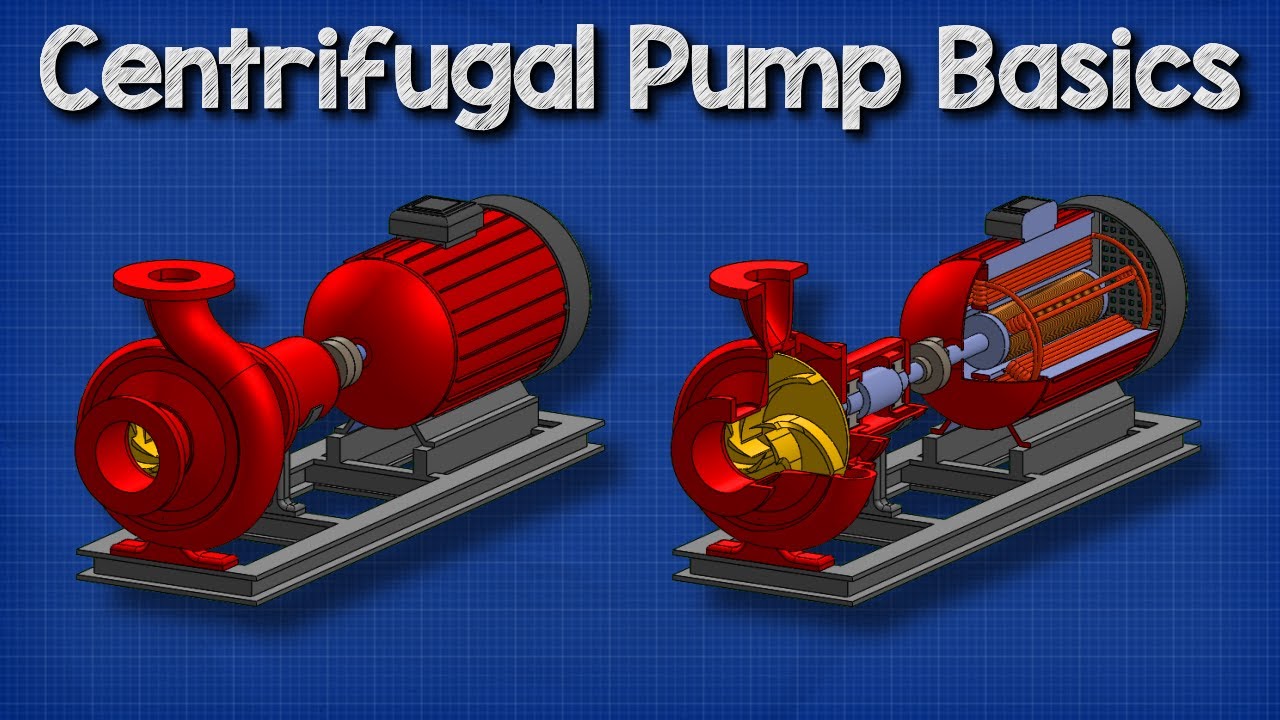

TLDRThis video explains how centrifugal pumps work and how to maintain them for reliable, efficient operation. It covers core components — impeller, motor, bearings, casing, seals (mechanical and packing), wear rings, and magnetic drives — and shows how impeller design, speed, and system head determine flow and pressure. Key maintenance points include correct alignment, seal and packing adjustment, managing seal chamber pressure, using shaft sleeves, and replacing wear rings. The program also explains priming, flooded suction versus suction lift, the role of check/foot valves, and common failure causes like air ingress, cavitation, and improper clearances, with practical tips for troubleshooting.

Takeaways

- 😀 Centrifugal pumps are commonly used across industries to move fluids, and understanding their operation is key to proper maintenance and identifying potential issues.

- 😀 The principle of operation is based on centrifugal force, which pushes fluid outward from the center when the impeller spins, creating pressure for fluid movement.

- 😀 Key components of centrifugal pumps include the impeller, motor, shaft, seals, casing, and discharge side, all of which contribute to the pump's operation and efficiency.

- 😀 The impeller’s design—such as curved blades or shrouded designs—affects the pressure, flow rate, and efficiency of the pump, and should be replaced with compatible parts to avoid performance changes.

- 😀 Proper alignment of the motor and pump shaft is essential for preventing excessive wear on bearings, shafts, and seals, ensuring efficient and reliable operation.

- 😀 Pump seals prevent fluid leakage or air entry and need regular maintenance to avoid issues like cavitation, which can cause severe damage to the impeller and housing.

- 😀 Two common types of seals in centrifugal pumps are mechanical seals and packing seals, with the mechanical seal being preferred for its better sealing properties and longer lifespan when properly maintained.

- 😀 A properly installed mechanical seal relies on smooth surfaces and correct pressure to provide lubrication and flushing, preventing seal damage from contaminants.

- 😀 Packed pumps use materials like Teflon or impregnated fabric to create a seal, but these require a controlled amount of leakage for lubrication to prevent overheating and damage.

- 😀 Pumps with a magnetic drive (mag drive pumps) use magnets instead of seals, which eliminates the risk of leakage as no shaft penetrates the casing.

- 😀 The suction side of the pump must be primed for the pump to work, and keeping it full of fluid is essential. Foot valves or check valves are commonly used to maintain priming in the suction line.

Q & A

What is the basic working principle of a centrifugal pump?

-A centrifugal pump works by using centrifugal force to move fluid. The impeller spins and moves the fluid away from the center, generating pressure that forces the fluid through the pump and into the discharge side of the system.

What are the main components of a centrifugal pump?

-The main components of a centrifugal pump include the impeller, the motor, bearings, the pump housing or casing, the shaft, seals, and the discharge side.

How does the shape of the impeller blades affect pump performance?

-The shape of the impeller blades determines the pressure and flow rate of the pump, as well as its overall efficiency. Different impeller designs are used for specific applications to optimize performance.

Why is pump alignment important?

-Correct alignment of the motor and impeller is crucial to avoid excessive wear on bearings, shafts, and seals. Even minor misalignment can lead to quick failure and inefficiency.

What role does a pump seal play, and what are the two main types?

-A pump seal prevents leakage of fluid and protects the shaft. The two main types of seals are mechanical seals, which are smooth and contact the shaft and housing, and packing seals, which use material packed around the shaft.

What is cavitation, and how is it related to seals in centrifugal pumps?

-Cavitation occurs when air leaks into the pump, causing bubbles to form under pressure. These bubbles explode, damaging the impeller and pump housing. Proper seal maintenance is essential to prevent cavitation.

What is the difference between a packed seal and a mechanical seal?

-A packed seal uses material packed around the shaft, requiring some leakage for lubrication, while a mechanical seal uses smooth, polished surfaces to prevent leakage and generally does not leak at all when properly installed.

What is the purpose of a wear ring in a centrifugal pump?

-Wear rings are replaceable components in the pump housing and impeller that reduce wear and tear. They help maintain proper clearances and ensure consistent pump efficiency, and only the wear rings are replaced when worn, not the entire casing.

How does priming affect the operation of a centrifugal pump?

-Priming is necessary for a centrifugal pump to operate. If the suction side is not full of fluid, the impeller will turn in air and the pump will not be able to generate pressure. A check valve or foot valve can help maintain prime.

What is the difference between flooded suction and suction lift?

-Flooded suction occurs when the fluid supply is above the pump, making it easier for the pump to operate. Suction lift occurs when the pump has to pull fluid up from below, requiring more work and reducing pump output.

Why is it important to match a pump to its application?

-Matching a pump to its application is important because changes in pump parts, wear, or incorrect settings can affect the entire system's performance, such as the pressure, flow rate, and efficiency.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

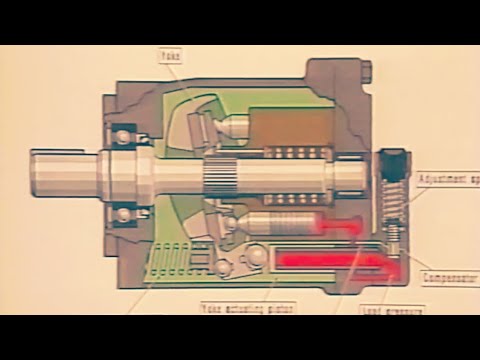

Hydraulic Training Series - Chapter 2 - Hydraulic Pumps

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Advanced Process Control - Minimum flow control for centrifugal pumps

Centrifugal Pump Hindi | Centrifugal Pump parts and Working

Do Pumps Create Pressure or Flow?

POMPA | Definisi Pompa | Jenis-jenis Pompa

5.0 / 5 (0 votes)