Centrifugal Pump Hindi | Centrifugal Pump parts and Working

Summary

TLDRThis video explains the working of a centrifugal pump, focusing on its key components and operation. It covers how the pump lifts water from a low point to a high point using centrifugal force, highlighting essential parts like the impeller, suction head, delivery head, and the importance of energy input for proper functioning. The presenter delves into the physics behind centrifugal force, explaining concepts like pressure differences, velocity, and the risks of cavitation. Real-life applications and practical considerations for using centrifugal pumps are also discussed, making the topic accessible and engaging for viewers.

Takeaways

- 😀 Centrifugal pumps are designed to lift water from a lower to a higher point, transferring it from a low-level point to a high-level point.

- 😀 The main components of a centrifugal pump include the impeller, casing, suction pipe, delivery pipe, and strainer.

- 😀 The pump works by creating a centrifugal force that helps lift and transfer the water. This force is generated by the rotation of the impeller.

- 😀 The 'suction head' and 'delivery head' represent the height from where the water is sucked and where it is delivered.

- 😀 The pump uses mechanical energy to rotate the impeller, which in turn helps in the movement of water from one point to another.

- 😀 The working principle of a centrifugal pump involves converting kinetic energy into pressure energy through the process of fluid acceleration and deceleration.

- 😀 The speed and power of the impeller determine how much water can be lifted and at what pressure it can be delivered.

- 😀 The strainer in the pump ensures that no debris or unwanted materials enter the pump, keeping it functioning smoothly.

- 😀 If the suction head is too high or the pump is operated at too great a depth, cavitation can occur, causing damage to the pump.

- 😀 The centrifugal pump operates best within a certain range of pressure and height, and operating it beyond these limits may lead to inefficiencies and mechanical issues.

- 😀 The pump requires electrical or mechanical energy to rotate the impeller and achieve the necessary velocity for water movement.

Q & A

What is the primary function of a centrifugal pump?

-The primary function of a centrifugal pump is to lift water from a low point and move it to a higher point, using centrifugal force.

What are the main components of a centrifugal pump?

-The main components of a centrifugal pump include the impeller, suction head, delivery head, and strainer.

How does the impeller work in a centrifugal pump?

-The impeller creates centrifugal force by rotating, which pushes water outward from the center of the pump, generating pressure to move the water through the system.

What role does energy play in the operation of a centrifugal pump?

-Energy, either electrical or mechanical, is required to rotate the impeller. This energy is converted into kinetic energy that drives the movement of water.

What is cavitation in a centrifugal pump, and why is it a problem?

-Cavitation occurs when the pressure at the suction head drops too low, causing bubbles to form and collapse inside the pump. This can damage the pump and reduce its efficiency.

What factors affect the suction head in a centrifugal pump?

-The suction head is affected by the height from which water is being lifted, the pipe diameter, and the pressure created at the inlet. If the suction pressure is too low, it can lead to cavitation.

What is the relationship between the diameter of the pump pipe and water velocity?

-As the diameter of the pipe increases, the velocity of the water decreases. This affects the pressure and kinetic energy, influencing the pump's performance.

What is the purpose of a strainer in a centrifugal pump?

-A strainer is used to filter out debris and dirt from the water before it enters the pump, preventing damage to the system and ensuring smooth operation.

How does centrifugal force help move water through the pump?

-Centrifugal force pushes water outward from the center of the impeller, creating a high-pressure area at the outer edges of the pump and a low-pressure area at the center, which drives the water through the system.

Why is it important to manage the suction head properly in centrifugal pumps?

-Managing the suction head is crucial to avoid cavitation. Too deep a suction head can lower the pressure too much, leading to cavitation and damage to the pump.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Centrifugal Pumps

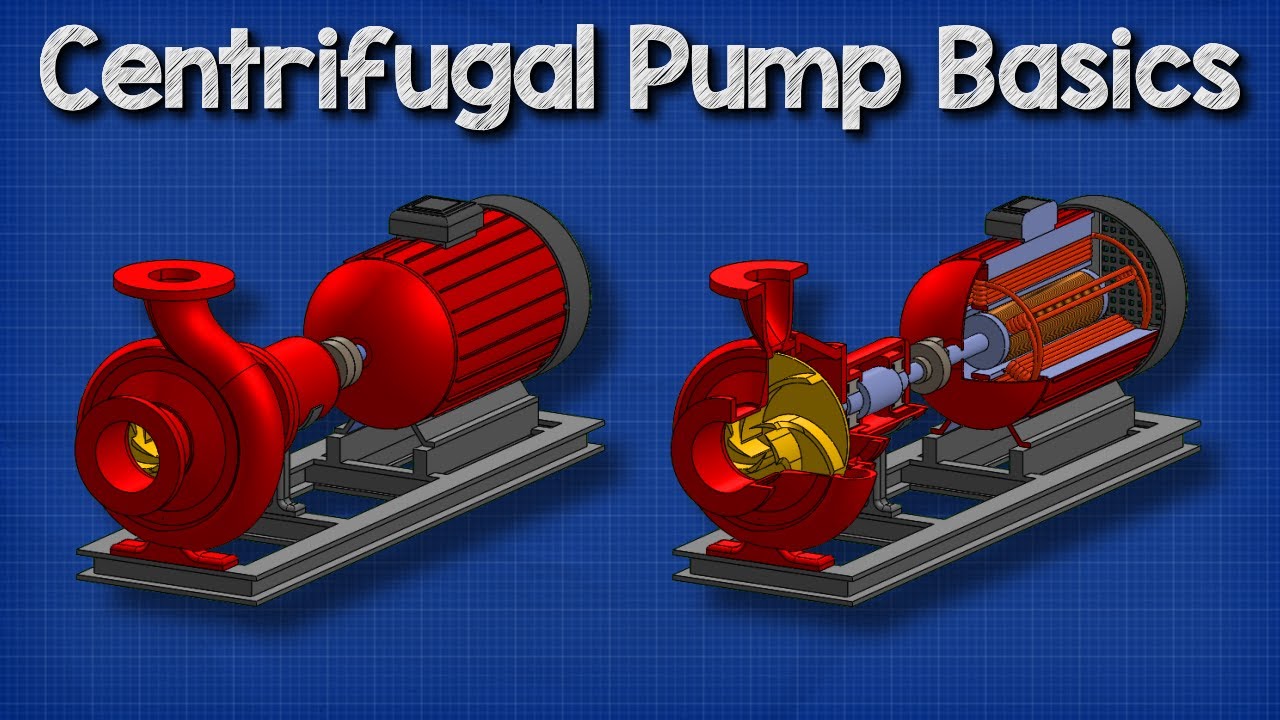

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Basic Principles and Energy Transfer in Centrifugal Compressor Part - I

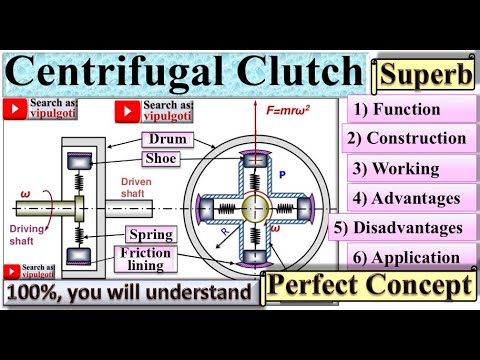

Centrifugal clutch, #Clutch, Function and working of Clutch, #Centrifugal #GTU #BME

Pump Performance Curve Explained | Master the Pump Curve for Optimal Results | Pump Curve

cara kerja bahan bakar diesel (Tipe Distributor)

5.0 / 5 (0 votes)