Classification of Plain Carbon Steels

Summary

TLDRThe script discusses the classification of steel based on carbon content, highlighting low, medium, and high-carbon steels. Low-carbon steels (up to 0.3% carbon) are easily welded, while medium-carbon steels (0.3% to 0.6% carbon) and high-carbon steels (0.6% to 1% carbon) are more prone to forming martensite, a hard microstructure that can cause cracking during welding. Preheating the steel helps to control cooling rates and reduce the likelihood of martensite formation, preventing cracks in both the weld and heat-affected zone.

Takeaways

- 😀 Low carbon steel contains up to 3% carbon by weight and is commonly used for nails and welding electrodes.

- 😀 Medium carbon steel, with 3-6% carbon, is used for applications like gears and crankshafts.

- 😀 High carbon steel, containing 0.6-1% carbon, is used for tools like dyes, cold chisels, and springs.

- 😀 Low carbon steels are generally easy to weld and do not require special heat treatments, except in some cases like thick sections or weldments with high joint restraint.

- 😀 Low carbon steel doesn't have enough carbon to form martensite, making it less prone to hardening during cooling.

- 😀 Medium and high-carbon steels can form martensite if cooled too quickly, leading to hardening and potential cracking.

- 😀 The tendency of steel to form martensite when cooled too rapidly is known as its 'hardenability.'

- 😀 Preheating the base metal before welding helps control cooling speed and reduces the chances of martensite formation.

- 😀 Without preheating, the surrounding cold metal acts as a heat sink, causing the weld to cool too quickly and increasing the risk of cracks.

- 😀 Preheating the base metal allows the heat from welding to stay within the weld zone, promoting slower cooling and reducing cracking risk.

Q & A

What are the different classifications of steel based on carbon content?

-Steel is classified as low carbon, medium carbon, or high carbon based on the percentage of carbon it contains.

What is the carbon content of low carbon steel?

-Low carbon steel contains up to 0.3% carbon by weight.

What are some applications of low carbon steel?

-Low carbon steel is used to make nails and welding electrodes.

How much carbon does medium carbon steel contain?

-Medium carbon steel contains between 0.3% and 0.6% carbon by weight.

What are the common uses of medium carbon steel?

-Medium carbon steel is commonly used for making gears and crankshafts.

What is the carbon content of high carbon steel?

-High carbon steel contains between 0.6% and 1% carbon by weight.

What are some applications of high carbon steel?

-High carbon steel is used for making dyes, cold chisels, and springs.

Why is low carbon steel easy to weld?

-Low carbon steel is easy to weld because it doesn’t have enough carbon to form martensite, a hard structure that can complicate welding.

What is the significance of martensite formation in steel?

-Martensite is a hard microstructure that can form if steel cools too quickly, leading to brittleness and potential cracking.

How does preheating help prevent martensite formation during welding?

-Preheating the base metal helps retain heat in the weld, allowing it to cool more slowly and reducing the chances of martensite formation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Guide to Understanding Steel | Materials Talk Series

Why is the carbon content in steel so important?

A Blacksmith's Introduction to Steel Types and Quality

Low Carbon Steel (Mild Steel)

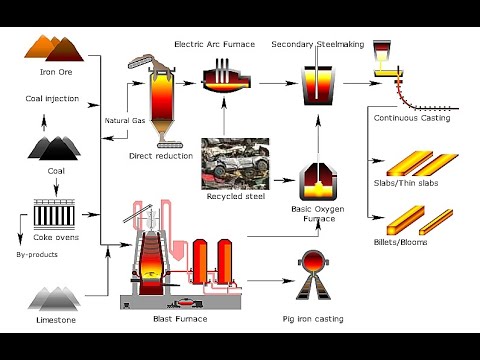

Complete Steel Making Process in easy steps ll. TATA VOCATIONAL TRAINING

04 MilkPlay Uso de aditivo para a redução das emissões em fazendas leiteiras

5.0 / 5 (0 votes)