Guide to Understanding Steel | Materials Talk Series

Summary

TLDRIn this video, Evan explains the four major types of steel defined by the American Iron and Steel Institute (AISI): Carbon, Alloy, Stainless, and Tool Steel. The video covers the characteristics and uses of various carbon steel types, including low, medium, high, and ultra-high carbon steels. It also delves into alloy steels, stainless steels, and tool steels, highlighting their properties and applications. From everyday products like knives to specialized tools and aerospace materials, this comprehensive guide explores the versatility of steel in various industries.

Takeaways

- 😀 Carbon steel is highly versatile, with its properties varying based on carbon content, affecting hardness, strength, ductility, and weldability.

- 😀 Carbon steel is categorized into four types: low/mild, medium, high, and ultra-high carbon steel, each with specific characteristics.

- 😀 Low Carbon Steel (Mild Steel) contains 0.04-0.3% carbon, making it malleable, ductile, tough, and easy to weld.

- 😀 Medium Carbon Steel (0.31-0.6% carbon) is stronger and harder than mild steel but more difficult to weld and form, commonly used in large or forged parts.

- 😀 High Carbon Steel (0.61-1.5% carbon) is extremely hard and brittle, making it difficult to bend, weld, or cut, often used in tools.

- 😀 Ultra-High Carbon Steel (1.51-2% carbon) can be heat-treated to exceptional hardness, typically used for specialist knives, axles, and punches.

- 😀 Alloy steels are steels alloyed with elements other than carbon, improving properties like strength, toughness, corrosion resistance, and wear resistance.

- 😀 Low-alloy steels contain 1-5% alloy content, are easily weldable with proper precautions, and include High Strength Low Alloy steels with specific mechanical properties.

- 😀 High-alloy steels have alloy levels above 10%, offering outstanding properties for specific applications.

- 😀 Stainless Steel contains at least 10.5% chromium, providing corrosion resistance, hardness, and strength, and is used in a wide range of industries.

- 😀 Tool steel is designed for making tools, with major alloying elements like tungsten, chromium, vanadium, and molybdenum, and it is classified into types based on hardness and intended use.

Q & A

What is the primary alloying element in carbon steel?

-The primary alloying element in carbon steel is carbon.

How does the carbon content affect the properties of carbon steel?

-As the carbon content in carbon steel increases, the steel becomes harder and stronger but also less ductile, more brittle, and harder to weld.

What are the four types of carbon steel based on carbon content?

-The four types of carbon steel are low (mild), medium, high, and ultra-high carbon steel.

What are the characteristics of low carbon steel?

-Low carbon steel, also known as mild steel, has a carbon content of 0.04–0.3%. It is malleable, ductile, tough, easy to weld, and relatively cheap.

What is the primary difference between medium carbon steel and low carbon steel?

-Medium carbon steel has a carbon content of 0.31–0.6%. It is stronger and harder than low carbon steel but more difficult to weld and form.

What are the common uses of high carbon steel?

-High carbon steel, with a carbon content ranging from 0.61–1.5%, is extremely hard and brittle. It is often used in applications requiring hardness, such as tools, knives, and other cutting instruments.

What makes ultra-high carbon steel unique?

-Ultra-high carbon steel, with a carbon content ranging from 1.51–2%, can be heat-treated to achieve exceptional hardness. It is commonly used for specialist tools like knives, axles, and punches.

What is alloy steel and how is it different from carbon steel?

-Alloy steel is carbon steel that has been alloyed with additional elements, such as manganese, chromium, nickel, and others. These elements enhance properties like strength, toughness, wear resistance, and corrosion resistance.

What is the difference between low-alloy and high-alloy steels?

-Low-alloy steels contain 1–5% alloy content, while high-alloy steels contain more than 10% alloy content, providing superior properties like strength and resistance to corrosion.

What is the defining characteristic of stainless steel?

-Stainless steel contains at least 10.5% chromium, which gives it its signature corrosion resistance, along with improved hardness and strength.

Why is stainless steel used in such a wide range of applications?

-Stainless steel is highly versatile and can be found in applications ranging from medical equipment and cutlery to aircraft and spacecraft, due to its resistance to corrosion and ability to withstand extreme conditions.

What are the primary elements that make up tool steel, and what is it commonly used for?

-Tool steel is primarily alloyed with tungsten, chromium, vanadium, and molybdenum. It is used for making tools due to its hardness, resistance to abrasion, and ability to maintain a sharp cutting edge at high temperatures.

What are the six major types of tool steel based on their characteristics or uses?

-The six major types of tool steel are: Water Hardening, Cold-working, Shock Resistant, High-Speed, Hot Working, and Special Purpose.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

The Ultimate Guide To Understanding Steel Grades

IGCSE Chemistry Edexcel Ch 18 - Extraction of Metals - Dr. Hanaa Assil

Which Shackle Should You Be Using?

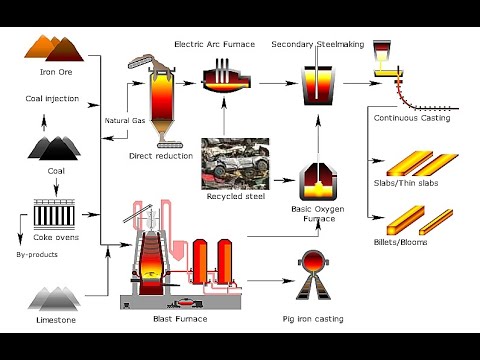

Complete Steel Making Process in easy steps ll. TATA VOCATIONAL TRAINING

Steel Types - Stainless Steel Vs Carbon Steel Explained.

Effects of alloying Elements on the Properties of steel. ||Engineer's Academy||

5.0 / 5 (0 votes)