Dasar sistem pneumatic

Summary

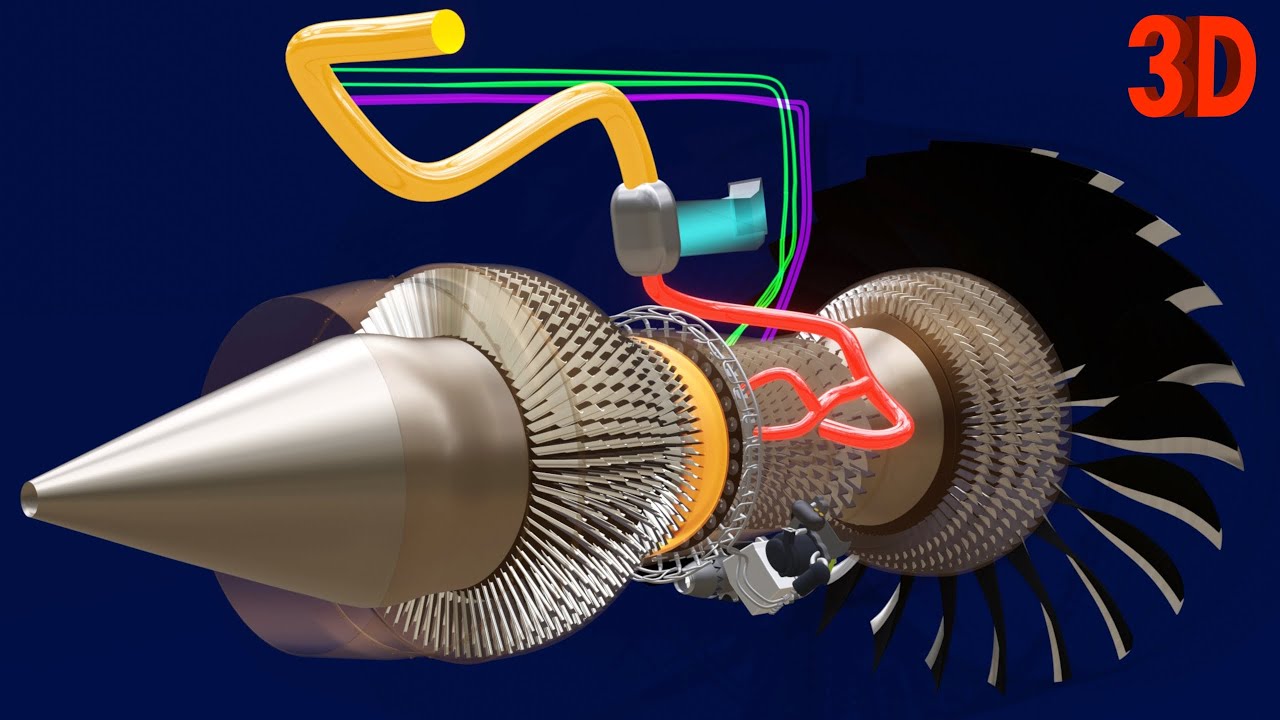

TLDRThis video explains the fundamentals of pneumatic systems, comparing them with hydraulic systems. Pneumatics uses compressed air to drive mechanical movements, as opposed to hydraulic systems, which rely on incompressible fluids like oil. Key components such as compressors, filters, regulators, lubricators, and actuators are discussed, along with their functions in controlling airflow and mechanical movements. The video also covers the advantages and disadvantages of pneumatic systems, such as their accessibility, cleanliness, and safety, as well as issues like noise, limited force transfer, and potential freezing or condensation problems.

Takeaways

- 😀 Pneumatic systems utilize compressed air to generate mechanical movement, in contrast to hydraulic systems that use fluids like oil.

- 😀 The term 'pneumatic' comes from the Greek word 'pneuma,' meaning breath or air, highlighting its reliance on air pressure.

- 😀 Pneumatic systems are commonly used in automotive applications, including brakes, shock absorbers, and suspension systems.

- 😀 The main difference between hydraulic and pneumatic systems is the fluid used: hydraulic systems use incompressible fluids, while pneumatic systems use compressible air.

- 😀 Pneumatic systems work at lower pressures (550-600 KPA) compared to hydraulic systems, which operate at much higher pressures (6.9 to 34 MPA).

- 😀 Pneumatic systems operate in a broader temperature range, with a maximum of 180°C, compared to hydraulic systems, which have a maximum of 70°C.

- 😀 The main components of a pneumatic system include the compressor, air filter, regulator, lubricator, control valve, and actuator.

- 😀 A compressor is used to draw in atmospheric air and compress it, which is then stored in a tank and distributed through pipes for use in the system.

- 😀 The efferail SRL (filter, regulator, lubricator) is a combination of components that cleans and conditions the air before it enters the pneumatic system.

- 😀 Pneumatic systems have both advantages, such as being environmentally friendly and safe, and disadvantages, such as noise, limited force transfer, and potential air leakage.

Q & A

What is the main difference between a hydraulic system and a pneumatic system?

-The main difference between a hydraulic system and a pneumatic system is the type of fluid used. Hydraulic systems use incompressible fluids like oil, while pneumatic systems use compressible fluids, specifically air, to transmit force.

What is the function of a compressor in a pneumatic system?

-The function of a compressor in a pneumatic system is to intake atmospheric air and compress it to a certain pressure, which is then stored in a reservoir tank for later use in the system.

What does the acronym 'Effair' stand for in the context of a pneumatic system?

-The acronym 'Effair' stands for Filter, Regulator, and Lubricator. These components are essential for filtering out impurities, regulating air pressure, and ensuring proper lubrication in the pneumatic system.

How does a liquid separator work in a pneumatic system?

-A liquid separator works by using centrifugal force to separate water particles from the compressed air. The water collects at the bottom of the separator, while the dry air rises to the top and continues through the system.

What is the role of a regulator in a pneumatic system?

-The regulator controls the air pressure in the pneumatic system. It adjusts the air pressure to the desired level, allowing the system to operate at the correct pressure for various applications.

Why is lubrication important in a pneumatic system?

-Lubrication is important in a pneumatic system because it reduces friction between moving parts. Proper lubrication helps prevent wear and tear on actuators and other components, ensuring smoother operation and longer system life.

How does a valve control the flow of air in a pneumatic system?

-A valve in a pneumatic system controls the direction of air flow by using a piston. The piston is actuated by an electrical signal, which either opens or closes different air pathways to direct the compressed air to the desired actuator.

What is the purpose of an actuator in a pneumatic system?

-The purpose of an actuator in a pneumatic system is to convert the compressed air's energy into mechanical motion, such as pushing, pulling, or lifting objects in various applications.

What are some advantages of using pneumatic systems over hydraulic systems?

-Some advantages of pneumatic systems include the easy availability of air, lower risk of contamination, and less maintenance since air is clean and abundant. Pneumatic systems are also safer in terms of fire hazards compared to hydraulic systems.

What are some disadvantages of pneumatic systems?

-Some disadvantages of pneumatic systems include noise pollution caused by the release of compressed air, limited force transfer, and the potential for leaks and inefficiency if the system is not properly maintained.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)