Manajemen Produksi Ep.04 Manajemen Bahan Baku

Summary

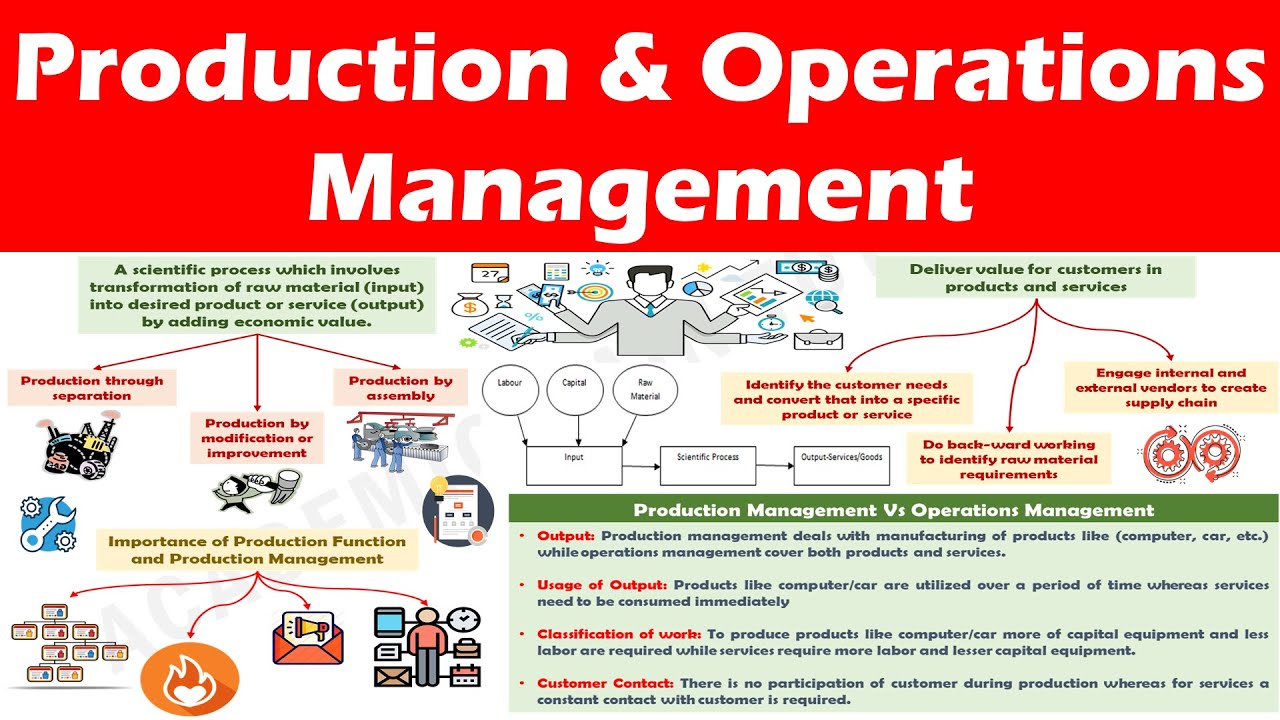

TLDRIn this engaging lecture on production management, the instructor explores the critical aspects of raw material management, emphasizing its role in reducing costs and enhancing efficiency in production processes. Key topics include planning, monitoring, and purchasing raw materials, along with the importance of collaboration across various production units. The discussion also touches on the significance of standardization, value analysis, and the just-in-time system. Overall, the session aims to equip students with a comprehensive understanding of raw material management and its impact on operational success.

Takeaways

- 😀 Understanding raw material management is crucial for reducing costs and improving efficiency in the production process.

- 📊 Effective raw material management requires collaboration across different production units, including purchasing, storage, and quality control.

- 🛠️ The planning and supervision of raw materials are essential to ensure availability and maintain quality, preventing production delays.

- 📝 Simplification in raw material management aims to streamline processes to avoid unnecessary complexity and inefficiency.

- 📦 Establishing a structured purchasing process helps ensure a steady supply of raw materials, minimizing disruptions in production.

- 🔍 Standardization in production ensures that products meet consumer demands and company standards, often through quality control measures.

- 🏪 Good management of retail operations is vital, including maintaining inventory and ensuring a clean, organized shopping environment.

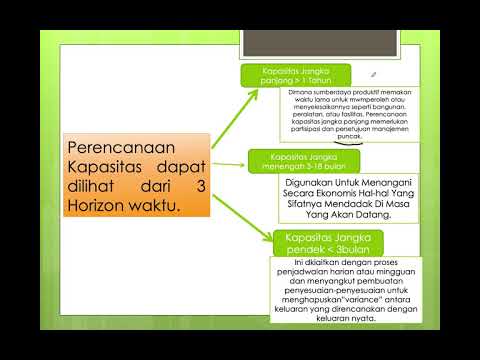

- 🔄 Factors affecting raw material planning include market trends, supplier relationships, and economic conditions, all of which must be monitored.

- 📈 Techniques for raw material planning include forecasting methods and creating detailed bills of materials for clarity in requirements.

- 🤝 Building and maintaining good relationships with suppliers is essential for sustainable sourcing and effective purchasing strategies.

Q & A

What is the primary goal of raw material management?

-The primary goal of raw material management is to reduce costs and optimize the handling of raw materials throughout all stages of the production process.

Why is collaboration essential in raw material management?

-Collaboration is essential because effective raw material management involves multiple departments, including purchasing, storage, and quality control, which must work together to ensure efficiency.

What are the four main functions of raw material management discussed in the lecture?

-The four main functions are planning and supervision, simplification, purchasing, and standardization.

How does planning and supervision contribute to raw material management?

-Planning and supervision ensure that raw materials are available when needed, preventing delays in production and maintaining operational efficiency.

What does simplification mean in the context of raw material management?

-Simplification refers to streamlining the production process to avoid unnecessary complexity, making it easier to convert raw materials into finished products.

What role does purchasing play in raw material management?

-Purchasing organizes the procurement of raw materials, ensuring that they are acquired in a timely manner and that supplier relationships are maintained.

What is the significance of standardization in raw material management?

-Standardization is significant because it ensures that all products meet established quality standards, which is maintained through quality control processes.

What are the micro factors affecting raw material planning?

-Micro factors include production capacity, rejection rates of materials, inventory levels, and communication within the workforce.

Can you name some macro factors that influence raw material planning?

-Macro factors include market trends, economic cycles, and government policies regarding imports.

What are some techniques mentioned for planning raw materials?

-The techniques mentioned include the overnight method, exponential smoothing, and time series analysis, which are used to forecast material needs.

Why is maintaining supplier relationships important in raw material management?

-Maintaining strong supplier relationships is important to ensure a consistent supply of raw materials, optimize costs, and enhance overall production sustainability.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)