Identifikasi dan Pengendalian Bahaya Mesin dalam Proses Produksi Ban Kendaraan

Summary

TLDRThis video, presented by Muhammad Fami, focuses on identifying and controlling machine hazards in vehicle tire production. Key hazards include potential injuries from cutting raw materials, mixing rubber, high-speed milling, and the installation and drying of tires. Control measures include regular machine maintenance, operator training, the use of personal protective equipment (PPE), speed regulation, and safety systems like emergency stop sensors. The video also outlines the tire production process, from raw material selection, rubber mixing, milling, and tire formation, to quality testing before market release.

Takeaways

- ⚙️ Identification of machine hazards in tire production is crucial, starting from raw material cutting to machine operation risks.

- 🔪 Cutting machines used for rubber can cause severe injuries if not properly operated.

- 🌀 Mixing and blending machines can be a source of danger if their safety is not properly maintained.

- ⚠️ High-speed rotating machines involved in rubber milling and processing pose significant risks to operators.

- 🔥 The tire fitting and drying machines also pose risks if operated carelessly, emphasizing the need for caution.

- 🔧 Regular machine maintenance is essential to optimize performance and reduce accident risks.

- 🎓 Operator training is necessary to ensure safe and correct machine usage.

- 🛡️ Personal protective equipment (PPE) like gloves, glasses, and ear protection must be worn by operators.

- ⏱️ Machines should operate at safe speeds to minimize the risk of accidents.

- 🚨 Emergency safety systems like automatic stop sensors should be installed to quickly halt machines in case of accidents.

Q & A

What is the main topic discussed in the script?

-The main topic is the identification and control of hazards related to machinery in the tire production process.

What are the potential hazards during the cutting of raw materials?

-The potential hazard during the cutting of raw rubber materials is the risk of serious injuries if the cutting machine is not operated correctly.

How can hazards be controlled during the mixing of materials?

-Hazards during material mixing can be controlled by ensuring the safety of the mixing and stirring machines to prevent accidents.

What are the risks involved in the milling and processing of rubber?

-The risks during milling and processing include accidents caused by high-speed rotating machines, which can be hazardous if safety measures are not followed.

What steps are mentioned to control machine-related hazards?

-Machine-related hazards can be controlled through regular maintenance, operator training, the use of personal protective equipment (PPE), controlling machine speed, and installing safety systems like emergency stop sensors.

What is the significance of routine maintenance in controlling hazards?

-Routine maintenance is crucial for keeping machines in optimal working condition and reducing the risk of accidents.

Why is operator training important in managing machine hazards?

-Operator training is important to ensure that workers know how to operate machinery safely and correctly, minimizing the risk of accidents.

What types of personal protective equipment (PPE) are recommended for machine operators?

-Recommended PPE includes gloves, safety glasses, and ear protection to safeguard operators when interacting with production machines.

How does controlling the machine speed help reduce injury risks?

-Controlling machine speed according to safety standards helps reduce the likelihood of accidents and injuries caused by high-speed operations.

What is the role of emergency stop sensors in hazard control?

-Emergency stop sensors are part of engineering controls and can quickly stop a machine in case of an accident, preventing further harm.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

PEMBELAJARAN RODA DAN BAN

Wheel Vibration on the Highway? Could be Out of Balance!

Bu videoyu izlemeden kış lastiği alma!

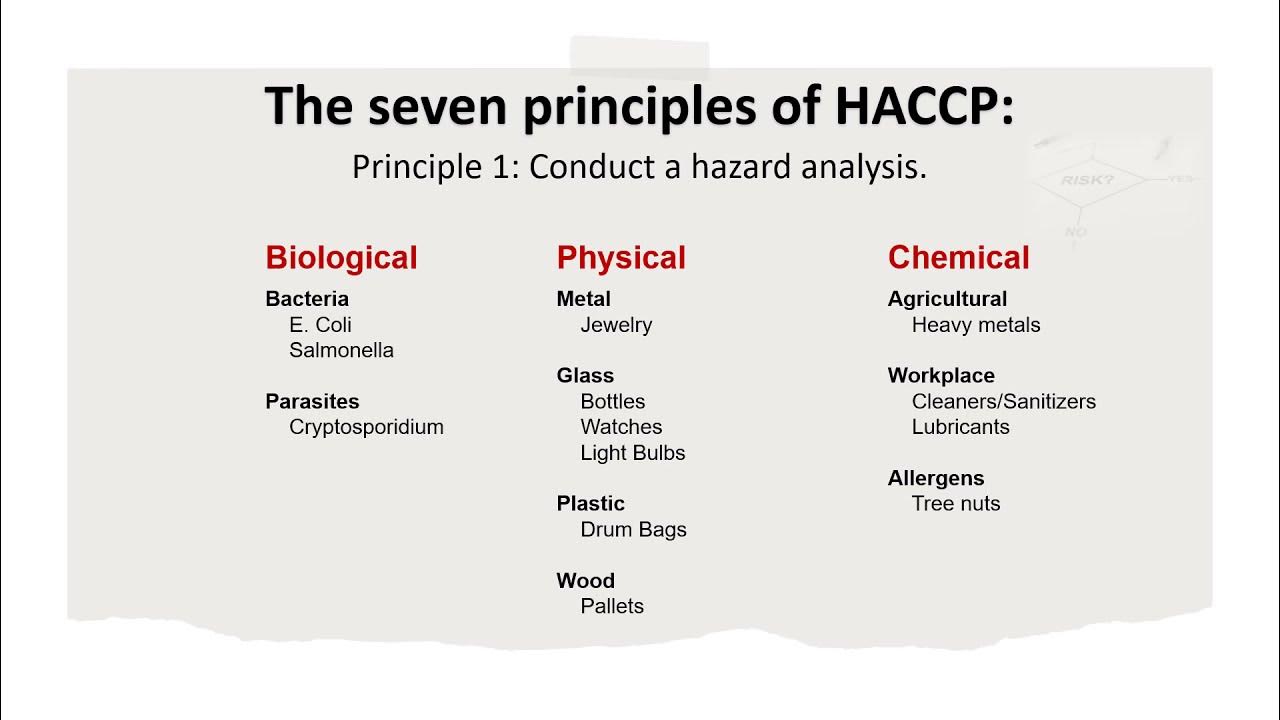

What is HACCP and what are the seven HACCP principles? HACCP Explained │ Food Safety

Panduan Penerapan Good Manufacturing Practice (GMP) Sesuai SNI CXC 1:1969 Revisi 2020

Everything You Need to Know About Tires on Your Car, Truck or SUV

5.0 / 5 (0 votes)