[Struktur Baja 2]: Perhitungan Sambungan Balok-Kolom Baja

Summary

TLDRThis tutorial provides an in-depth guide to calculating steel connections for beam-to-beam and beam-to-column joints in structural engineering. The process covers essential steps such as load factor calculations, bolt resistance, shear analysis, and design safety checks. Detailed methods are outlined for determining the number of bolts, spacing, and the use of welds in conjunction with bolts. The script emphasizes the importance of ensuring structural stability under various loads, ensuring that both the connections and the overall design are safe and efficient. It is a thorough resource for anyone learning about steel connection design in construction.

Takeaways

- 😀 The script introduces the topic of steel connection design, specifically focusing on the calculation of connections in steel structures.

- 😀 It begins with a review of the importance of connections in construction and the types of connections being discussed, such as beam-to-beam and beam-to-column joints.

- 😀 The first example discusses the connection between a main beam (balok induk) and a secondary beam (balok anak), highlighting the material properties and dimensions involved.

- 😀 Calculations are shown for the factors affecting the design, including load factors, shear force, and bolt strength, with a focus on determining the number of bolts required.

- 😀 The script explains the process of calculating the shear resistance of bolts and determining the proper number of bolts by dividing the applied load by the smallest shear resistance.

- 😀 It then discusses the importance of spacing between bolts and the minimum and maximum distances required for a safe connection design.

- 😀 For beam-to-column connections, the script provides an example with a steel beam (WF 500/200) and a column (300x300) and emphasizes the use of both bolted and welded connections.

- 😀 The calculation of shear and moment resistance for welded connections is also covered, with a focus on ensuring that the welded joint is capable of withstanding the applied forces.

- 😀 The importance of checking the adequacy of the design against the shear forces and moments is stressed to ensure safety and stability of the structure.

- 😀 Finally, the script concludes with a reminder to ensure that all calculations meet the safety standards for structural design, ensuring that the design is both functional and secure.

Q & A

What is the main topic discussed in the video script?

-The video script discusses the calculation and design of steel connections, particularly focusing on beam-to-beam (primary and secondary beams) and beam-to-column connections in structural steelwork.

What is the first step in designing the connection for a beam?

-The first step involves calculating the factored load using a combination of dead load (1.2D) and live load (1.6L) to determine the load that the connection must withstand.

What is the significance of calculating shear resistance in the connection design?

-Shear resistance is essential to ensure that the bolts and the steel connection can handle the shear forces without failing. It involves calculating the shear strength of the bolts and the pressure on the web of the beam.

How is the number of bolts required for a connection calculated?

-The number of bolts is calculated by dividing the load the connection will carry (P or R) by the smallest resistance value. The result is then rounded up to ensure a safe design.

What is the role of the thickness of the connecting plate in the design?

-The thickness of the connecting plate affects the spacing of the bolts and the overall strength of the connection. It must be designed to handle the stresses transmitted through the bolts.

Why are minimum and maximum bolt spacing important in the design process?

-The spacing between bolts must adhere to certain minimum and maximum values to ensure proper load distribution, minimize the risk of failure, and avoid weakening the structure.

What type of bolts and diameter is used in the discussed connection design?

-The design uses bolts with a diameter of 12 mm, and the steel used for the bolts is BJ-37, which is designed to handle the calculated loads.

What does the design check for shear and moment resistance involve?

-The design checks whether the connection can withstand both shear forces (from normal load) and moment forces (from bending) to ensure it remains stable and safe under all load conditions.

How is the connection between a beam and a column treated differently from the beam-to-beam connection?

-The beam-to-column connection is designed using both bolted and welded connections. For example, the script mentions using welds alongside bolts and ensuring that the welded area can handle the shear and moment forces.

What factors are considered when calculating the resistance of welded connections?

-The resistance of welded connections is calculated by considering the effective length of the weld, the type of steel, and the properties of the weld itself, ensuring it can handle the normal and shear forces as well as the moments applied.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Steel Connections Every Structural Engineer Should Know

CARA MENCARI UKURAN BALOK BETON || ukuran balok rumah 2 lantai

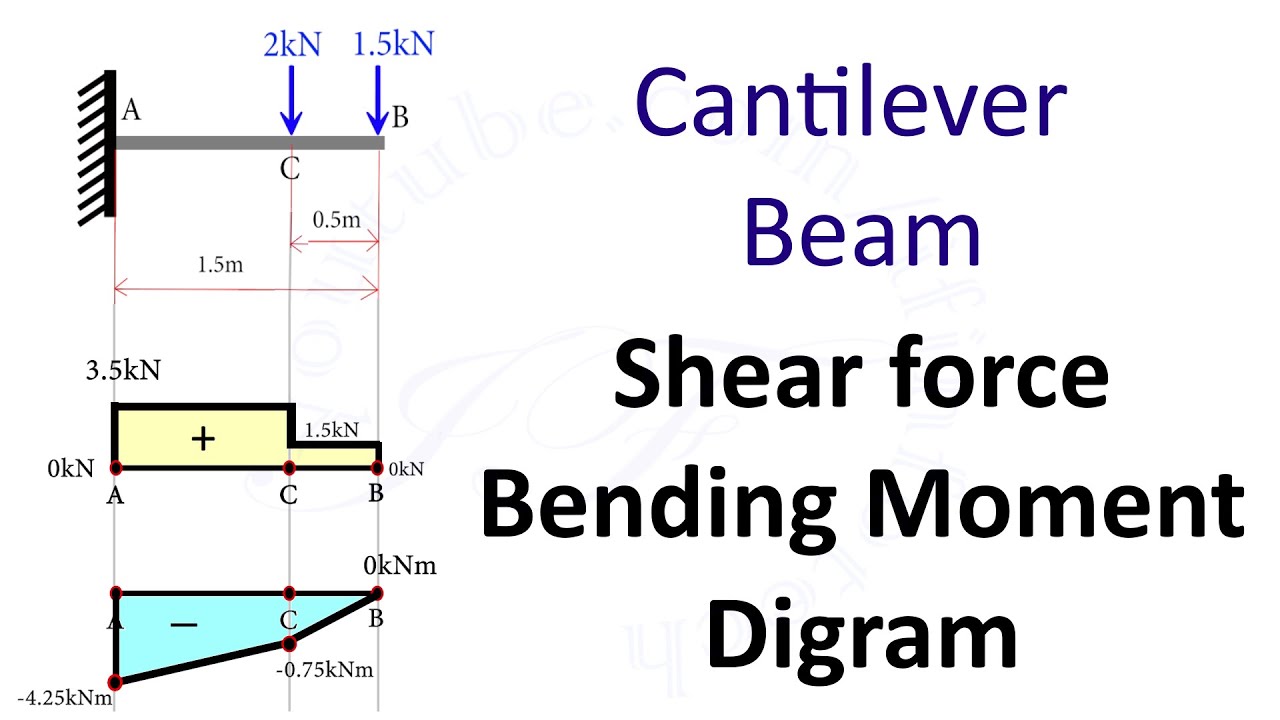

Cantilever Beam: Shear Force and Bending Moment Diagram [SFD BMD Problem 2] By Shubham Kola

ANALISA STRUKTUR 2 MATRIKS FLEKSIBILITAS SOAL & PEMBAHASAN#Matriksfleksibilitas#Flexibilitymatrix

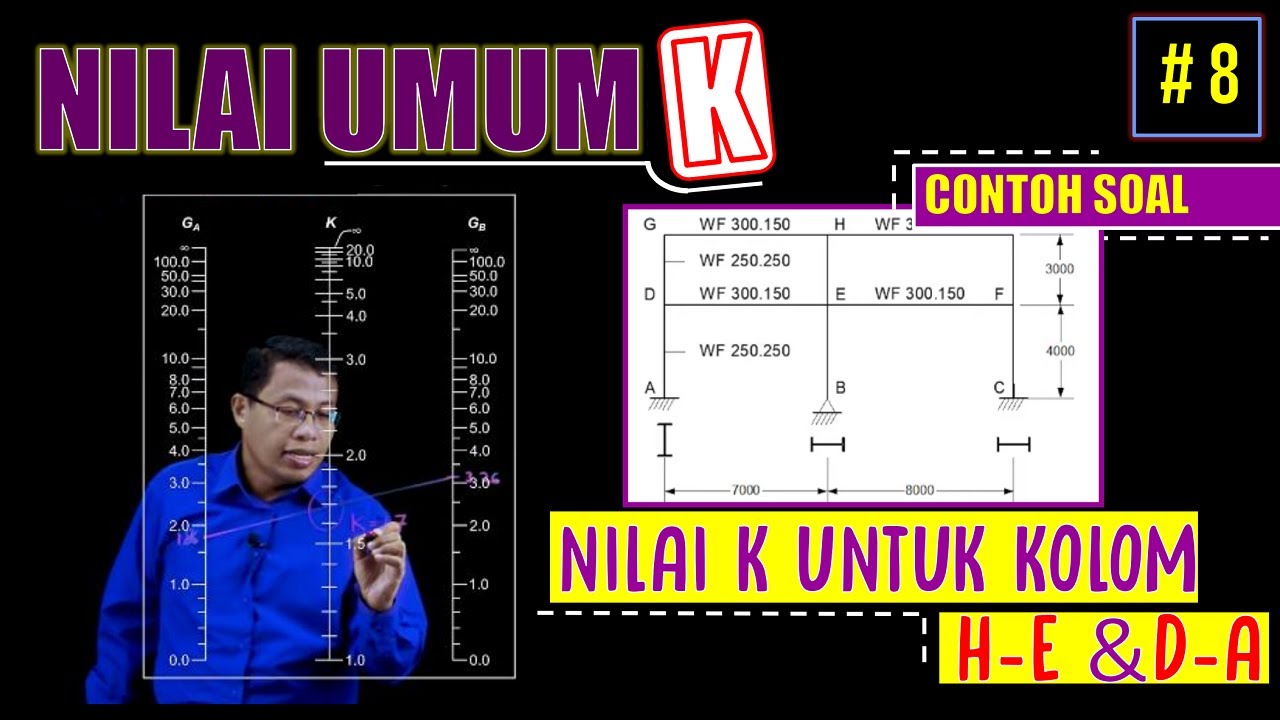

Contoh Perhitungan Nilai Umum K Batang Tekan Struktur Baja | Lightboard

Balok Penampang T SNI 2847-2019

5.0 / 5 (0 votes)