Tutorial Software BLOCPLAN

Summary

TLDRThis tutorial demonstrates the use of Blockplan software for designing initial layouts in factory facility planning. The video guides users through the process of setting up and running the software via Dosbox, entering facility data, and specifying proximity relationships between departments. It then covers the layout generation process, where the software suggests optimal layouts based on efficiency scores. Users are shown how to adjust and review these layouts, ultimately selecting the best option. The tutorial offers a step-by-step approach to using Blockplan for effective facility planning.

Takeaways

- 😀 Blockplan is a software tool for designing the initial layout of factory facilities.

- 😀 To run Blockplan, you must first open DOSBox and input specific commands to load the software.

- 😀 You can either load previously saved data or input new data manually when designing a layout.

- 😀 The first step in creating a layout is entering the number of departments, which is tailored to the specific case study (e.g., 8 departments).

- 😀 After entering the departments, you must input the name and area of each facility (e.g., parking area, warehouse).

- 😀 If there are any input errors (e.g., typos), the software allows you to update the department information as needed.

- 😀 Proximity between departments must be inputted based on a pre-designed Activity Relationship Chart (ARC).

- 😀 The software allows for correction of proximity data if any mistakes are made during entry, including adjusting coordinates between facilities.

- 😀 Users can set certain departments to fixed positions (e.g., security post), ensuring they stay in designated locations within the layout.

- 😀 After inputting all data, Blockplan generates multiple layout alternatives with scores for efficiency based on proximity and layout distances.

- 😀 The best layout is chosen based on its ADC (agency) score and REL (relative distance) score, ensuring optimal placement of departments.

- 😀 After selecting the best layout, users are prompted to save their design, which can then be reviewed for further refinement.

Q & A

What is the purpose of the Block software in this tutorial?

-The Block software is used to design the initial layout for facility planning in the context of factory layout design. It helps in organizing and arranging facilities effectively.

What is the first step in using the Block software for facility layout planning?

-The first step is to open the Dosbox application, which is an emulator for running the Block software, and then input a series of commands to set up the environment for running Block.

What is the significance of the 'Caps Lock' key when running the Block software?

-The 'Caps Lock' key needs to be turned on when typing the code to run the Block software. This is crucial for executing the commands properly.

What is the difference between 'Data from this' and 'Keyboard' options in the Block software?

-'Data from this' is used when you already have saved input data, while 'Keyboard' is used when you want to manually input new data from scratch.

How does the user input facility information in the Block software?

-The user inputs facility data such as the number of departments and their respective areas. For example, the area of 'parking' is inputted, followed by the area measurement, and this process continues for all facilities.

What should the user do if they need to correct a mistake in the inputted facility data?

-If there is a mistake in the inputted data, such as a typo, the user can choose to change the department information by selecting 'Y', entering the department number, and correcting the input.

What is the 'Activity Relationship Chart' (ARC) used for in the Block software?

-The ARC is used to determine the degree of closeness between two facilities. This information is inputted into the software to ensure that the facilities are arranged efficiently based on their relationships.

What happens after the user inputs the closeness scores between facilities?

-Once the closeness scores are inputted, the software may ask if the user wants to change any data. If not, the user can proceed to adjust the vector scores or confirm the data and continue.

How are the layout alternatives generated in the Block software?

-The software generates layout alternatives based on user inputs. The user can select the number of alternatives they want, and the software will automatically compute and display various layout options.

What are the key metrics used to evaluate the layout alternatives in the Block software?

-The key metrics include the 'ADC score' (Agency score), which evaluates the total closeness between facilities, the 'REL score' (Relative Distance score) that measures the layout's efficiency, and the total distance between departments. The higher the scores, the better the layout.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

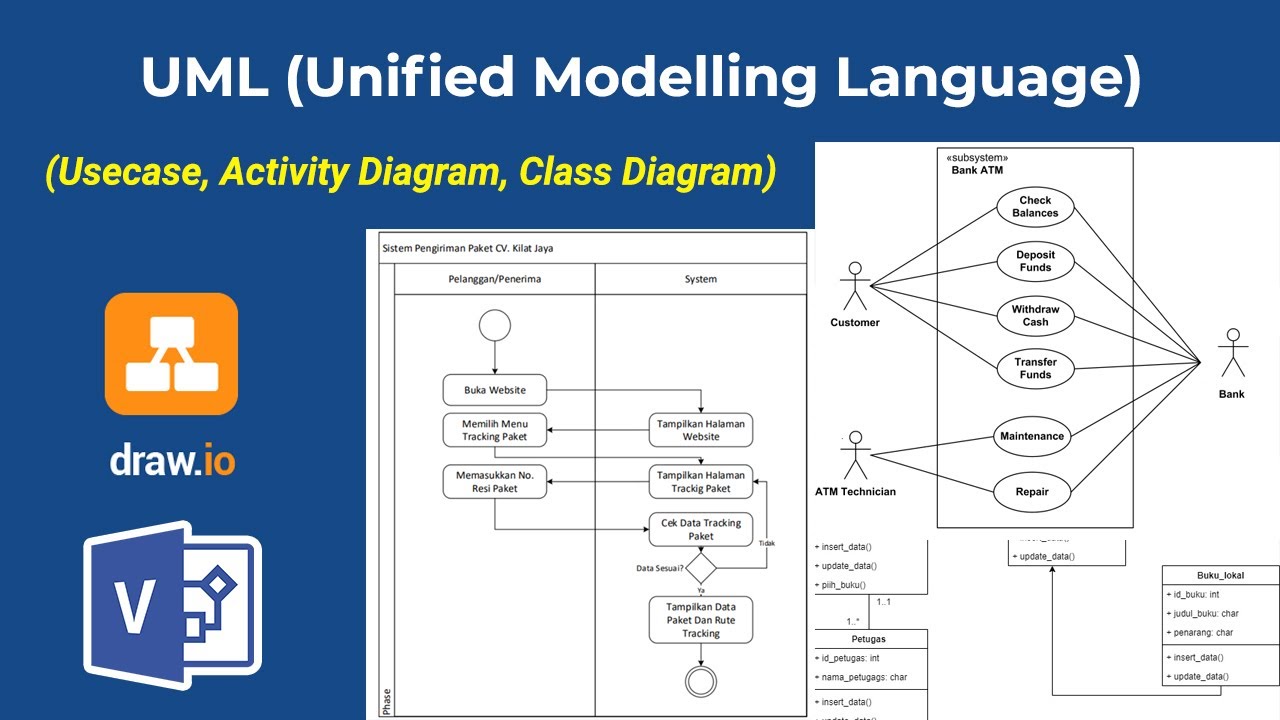

Apa itu UML? Beserta Pengertian dan Contohnya | Belajar UML & Perancangan Sistem

A practical guide to responsive web design

Pengaturan Dasar Wordpress dan Plugin Elementor

Tutorial Instalasi Diptrace

ServiceNow Telugu Series - Episode 05 |ServiceNow Forms and Form Designing |ServiceNow Telugu Videos

CSS Grid Layout In One Video | Complete Web Development Course #26

5.0 / 5 (0 votes)