6 Ways to Separate an Oil and Water Emulsion [Oil & Gas Industry Basics]

Summary

TLDRIn this video, the oil and gas industry’s separation principles are explored, focusing on the methods used to separate components like oil, water, gas, and solids from well fluids. Six key separation principles are discussed: heat, gravity separation, retention time, agitation, coalescing, and chemical demulsification. Each principle enhances the separation process, whether by lowering viscosity, utilizing density differences, extending fluid retention time, or applying chemicals. The video emphasizes the role of equipment like heater treaters, diverter plates, and mist eliminators in optimizing separation for efficient processing of well fluids.

Takeaways

- 😀 Emulsions in the oil and gas industry consist of oil, water, gas, and solids, and can be classified as water-in-oil or oil-in-water depending on the liquid volume ratios.

- 😀 Gas brought to the surface is typically wet gas, consisting of methane and liquid natural gases like ethane and butane.

- 😀 Separation of oil and gas emulsions is achieved through various principles to obtain valuable end products.

- 😀 Heat is used to separate liquids by lowering oil viscosity and increasing the density difference between oil and water.

- 😀 A heater treater is a vessel that applies heat to aid in separation, and its functionality is discussed further in training materials.

- 😀 Gravity separation relies on the density differences between the elements in the well stream, allowing water to separate naturally over time.

- 😀 Retention time is the duration that the fluid stays in a non-agitated state, and longer retention time results in better separation.

- 😀 Agitation occurs when fluid impacts a diverter plate, changing direction and velocity to break the surface tension and initiate separation.

- 😀 Coalescing is the process where water droplets merge to form larger drops, aiding in separation and occurring in mist eliminators.

- 😀 Chemical demulsification uses chemicals to weaken the surface tension between oil and water, enhancing coalescence and minimizing the need for heat or longer retention times.

Q & A

What is the composition of fluids when a well is produced?

-When a well is produced, the fluid comes to the surface as an emulsion of oil, water, gas, and solids.

How are emulsions classified in the oil and gas industry?

-Emulsions in the oil and gas industry are classified as either water-in-oil or oil-in-water, depending on the ratio of the volumes of liquids.

What is the typical composition of gas brought to the surface in the oil and gas industry?

-The gas brought to the surface is typically wet gas, composed of dry natural gas like methane, mixed with liquid natural gases like ethane and butane.

What is the role of heat in the separation process of oil emulsions?

-Heating an oil and water emulsion decreases the viscosity of oil, making it easier for gas and water molecules to separate. It also increases the density differences between oil and water.

What is a heater treater and how does it work?

-A heater treater is a vessel that uses the principle of temperature change to help separate oil from water by applying heat, which reduces viscosity and aids in the separation process.

What is gravity separation in the context of the oil and gas industry?

-Gravity separation relies on the different densities of elements in the well stream, allowing water to separate from oil over time in a non-turbulent state.

How does retention time affect separation efficiency?

-Retention time is the amount of time the fluid stays in a steady, non-agitated state. Longer retention time improves separation efficiency, as it allows more water to settle out by gravity.

How does agitation assist in the separation process of oil emulsions?

-Agitation helps to break the surface tension of liquids by changing their direction and velocity when the production fluid hits the diverter plate, which initiates the separation process.

What is coalescence and how does it relate to oil and water separation?

-Coalescence is the process where small water droplets come together to form larger drops, enhancing the separation of water from oil. This happens in devices like mist eliminators.

How do mist eliminators work to separate droplets from gas?

-Mist eliminators, such as vane and mesh types, cause the wet gas to change direction, causing droplets to collide, coalesce, and eventually fall out of the vapor stream due to inertial impaction.

What role do chemical demulsifiers play in the separation process?

-Chemical demulsifiers are chemicals that move to the oil and water interface, weakening the surface tension and enhancing coalescence. They reduce the need for high heat or long retention times during separation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Separação de Misturas Heterogêneas - Brasil Escola

Artificial Lift: Electric Submersible Pumps (ESP) in Oil & Gas Systems

Introduction to Oil & Gas Industry, Part 6: Production

Apa itu separator?

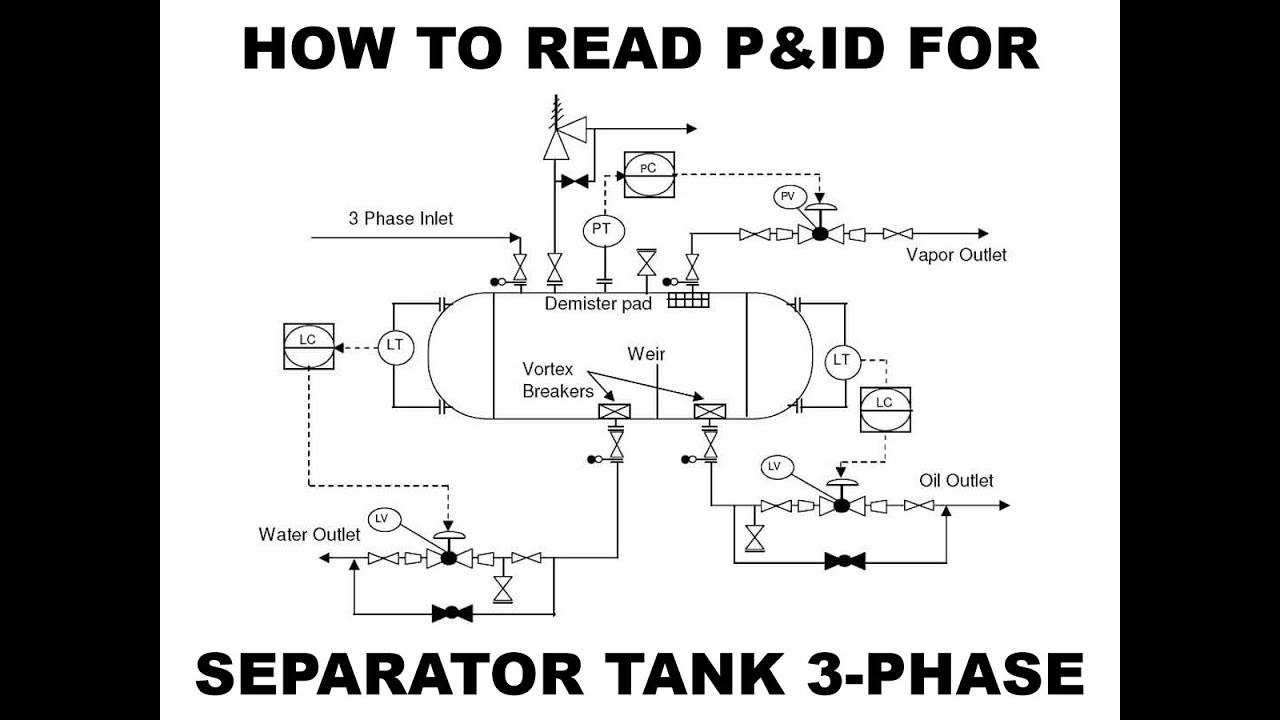

How To Read P&ID Diagram for Separator Tank (3-Phase) in Malay - Nazmi Ismail

FUNGSI DAN CARA KERJA SEPARATOR | PROSES PEMISAHAN MINYAK AIR DAN GAS |

5.0 / 5 (0 votes)