INSTALASI PENGOLAHAN AIR LIMBAH PRODUKSI JUTAAN AYAM!! BEGINILAH PROSESNYA #wwtp #ipal

Summary

TLDRThis video provides an in-depth look at the wastewater treatment process at PT Malindo Feedmill Tbk's poultry slaughterhouse in Purwakarta. The facility processes both production and domestic wastewater, beginning with collection and separation of oils and fats, followed by equalization and aeration to promote bacterial growth. The water undergoes coagulation, flocculation, and settling, with further treatment in bio-tanks. Finally, the water is disinfected with chlorine and tested to ensure its suitability for discharge into natural water bodies, ensuring a clean and environmentally responsible process.

Takeaways

- 😀 The wastewater treatment facility at PT Malindo Feedmill Tbk in Purwakarta processes both production and domestic wastewater.

- 😀 The initial step in wastewater treatment involves collecting liquid waste in a holding tank.

- 😀 Water is filtered through a series of screens (coarse, medium, and fine) to remove large particles and debris.

- 😀 Oil and grease separation is performed in a dedicated oil separation tank, utilizing gravity for the process.

- 😀 The wastewater then flows into an equalization tank, where aeration promotes bacterial growth to help break down organic materials.

- 😀 Flow meters are used to measure and regulate the inflow and outflow of water during the treatment process.

- 😀 Neutralization and coagulation treatments are applied to prepare the wastewater for the next stages of purification.

- 😀 In the flocculation phase, fine particles combine to form larger clusters (flocs) that are easier to remove.

- 😀 The sedimentation tank allows flocs to settle, separating clean water from the sludge.

- 😀 The treated water is sent through bio-treatment tanks to further break down organic waste using microorganisms.

- 😀 The final stage involves disinfecting the treated water with chlorine to eliminate remaining pathogens before environmental release.

Q & A

What is the main purpose of the wastewater treatment facility at PT Malindo Feedmill?

-The main purpose of the wastewater treatment facility at PT Malindo Feedmill is to support clean production and ensure environmental health by treating both production and domestic wastewater.

How is wastewater collected before treatment in the facility?

-Wastewater is collected in a holding tank that receives water from both the production process and domestic sources, which is then pumped into a primary channel for further treatment.

What role do the screen sections in the wastewater treatment process play?

-The screen sections, which are coarse, medium, and fine, help in filtering out larger particles from the wastewater before it moves to further treatment stages.

What happens in the oil separating tank?

-In the oil separating tank, the wastewater undergoes a process where oil and grease are separated from the water through gravity, with the oil and grease being removed for further processing.

What is the purpose of the equalization tank in the treatment process?

-The equalization tank helps to mix the wastewater and equalize the flow, promoting the growth of bacteria that aid in the biological treatment of the water.

What is the role of the diffuser in the equalization tank?

-The diffuser in the equalization tank injects air into the water to promote aeration, which helps in the growth of bacteria necessary for wastewater treatment.

How is the flow of wastewater measured during the treatment process?

-The flow of wastewater is measured in a flow meter box, which records the flow rate or discharge during the treatment process to ensure proper management.

What is the coagulation-flocculation process and where does it occur in the facility?

-Coagulation and flocculation are processes where chemicals are added to the wastewater to help particles clump together, forming 'flocs' that can then be removed from the water. This occurs in the neutralization and flocculation tanks.

How does the setting tank contribute to the wastewater treatment process?

-The setting tank allows for the sedimentation of solids, where heavier particles settle to the bottom while cleaner water overflows into the next stage of treatment.

What is the purpose of the chlorination process in the final stage of treatment?

-The chlorination process is used to disinfect the treated water by adding chlorine, ensuring that it meets environmental standards before being released into the environment or water bodies.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

PENGOLAHAN LIMBAH CAIR AGROINDUSTRI GULA - METODE FISIKA BIOLOGI

Pengolahan Limbah Cair Agroindustri Kelapa Sawit - Sistem IPAL | PT. Sulander Perkasa

Simulasi Proses Pengolahan Limbah Cair pada Industri Tekstil | Contoh WWTP pada PT Sritex

Lecture 03: Course outline.

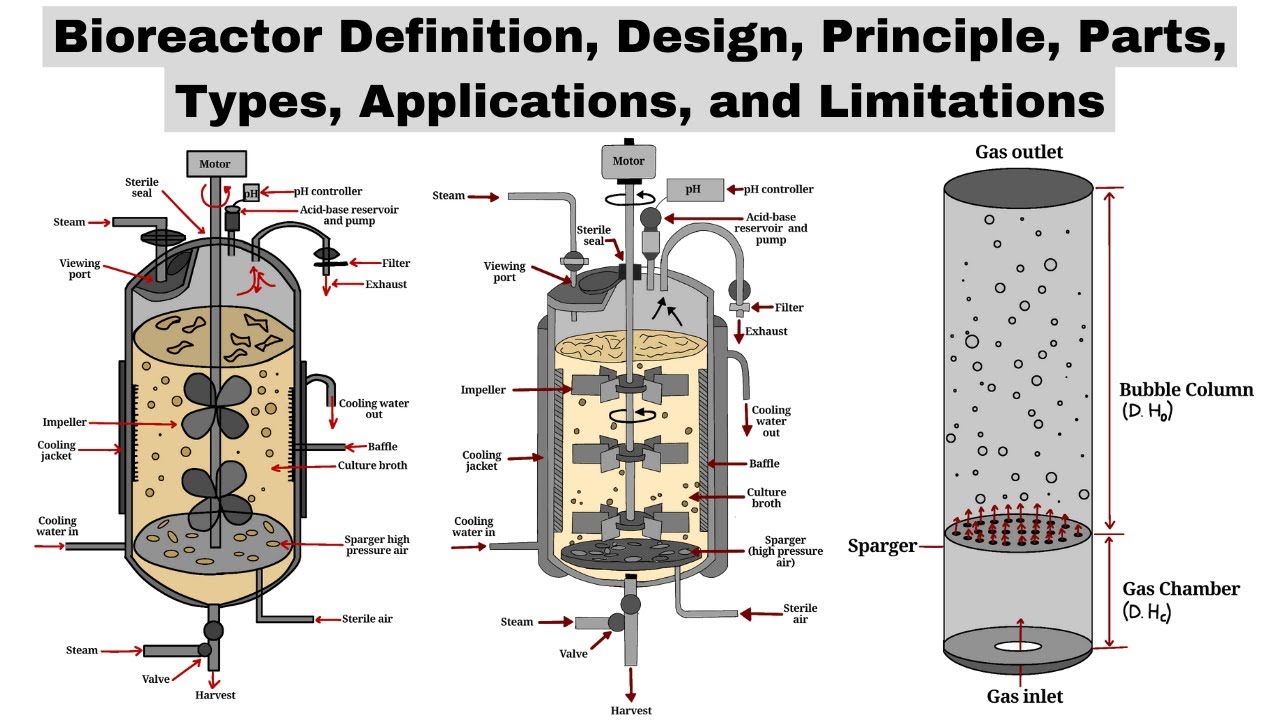

Bioreactors | Design, Principle, Parts, Types, Applications, & Limitations | Biotechnology Courses

Simulasi STP Gedung (Extended aeration (recycle)

5.0 / 5 (0 votes)