Bioreactors | Design, Principle, Parts, Types, Applications, & Limitations | Biotechnology Courses

Summary

TLDRThis video provides an in-depth look at bioreactors, explaining their definition, design, and the principles behind their operation. It covers essential components like fermentation vessels, aeration systems, and control mechanisms, as well as the different types of bioreactors, such as continuous stirred tank and bubble column fermenters. The video also highlights the various applications of bioreactors in industries like pharmaceuticals, wastewater treatment, and biochemical production. Finally, it addresses the limitations of bioreactors, including challenges with power consumption, nutrient supply, and maintenance. A comprehensive guide for anyone interested in biotechnological processes and bioreactor technology.

Takeaways

- 😀 Bioreactors are closed containers used in biological processes to cultivate microorganisms and produce metabolites or other products.

- 😀 They include systems for aeration, agitation, temperature control, pH regulation, and nutrient feeding to create optimal growth conditions for microorganisms.

- 😀 Bioreactor designs vary based on the scale of production, from small laboratory fermenters to large industrial systems, with materials chosen for their resistance to corrosion and pressure.

- 😀 The main components of a bioreactor include the fermenter vessel, aeration system, agitation system, heating and cooling apparatus, and sterilization mechanisms.

- 😀 The principle of a bioreactor is to maintain optimal conditions for microorganisms to transform substrates into desired products, facilitating biotransformation and bio-catalysis processes.

- 😀 Key parts of a bioreactor include fermenter vessels (glass or stainless steel), impellers for mixing, aeration devices like spargers, and feed ports for adding nutrients or adjusting pH.

- 😀 Bioreactors are used for a variety of purposes, including antibiotic production, enzyme synthesis, and wastewater treatment.

- 😀 There are several types of bioreactors, including continuous stirred tank reactors (CSTR), airlift fermenters, bubble column fermenters, and photobioreactors, each suited for specific applications.

- 😀 The application of different types of bioreactors depends on their design, with each type supporting different biochemical processes like fermentation, organic acid production, and biomass cultivation.

- 😀 While bioreactors offer many advantages, they also have limitations, such as high energy consumption, inefficient mixing in certain designs, and the need for regular maintenance or cleaning due to biofilm growth or other factors.

Q & A

What is a bioreactor and why is it important in biotechnology?

-A bioreactor is a closed container used in biological processes such as fermentation to grow microorganisms and produce products like enzymes, antibiotics, and biofuels. It maintains optimal conditions for growth, including temperature, pH, aeration, and agitation, ensuring efficient production.

What are the key parameters controlled in a bioreactor?

-The key parameters controlled in a bioreactor include temperature, pH, pressure, aeration, nutrient feeding, and liquid levels, all of which are necessary for optimal microbial growth and product formation.

What are the main components of a bioreactor?

-Main components of a bioreactor include the fermenter vessel, aeration system, impellers, heating and cooling apparatus, baffles, valves, and various control systems for monitoring parameters like temperature, pH, and oxygen concentration.

Why is agitation important in bioreactors?

-Agitation in bioreactors is important because it ensures the uniform mixing of cells and nutrients, helps distribute oxygen throughout the culture medium, and prevents clumping of microbial cells, which can affect growth and product yield.

What is the role of the aeration system in a bioreactor?

-The aeration system is crucial in bioreactors for providing oxygen to aerobic microorganisms. It typically includes spargers and impellers that help distribute oxygen evenly throughout the fermentation medium.

What are the advantages of using stainless steel over glass vessels in bioreactors?

-Stainless steel vessels are preferred in large-scale applications due to their ability to withstand high pressure, corrosion, and temperature variations. They are more durable and suited for industrial-scale fermentation compared to glass vessels, which are typically used in small-scale applications.

How does a photobioreactor work and what is it used for?

-A photobioreactor uses light, either natural or artificial, to power photosynthetic processes. It is used primarily for growing microorganisms like algae that produce valuable compounds such as beta-carotene, biofuels, and other photosynthetic products.

What is the function of baffles in a bioreactor?

-Baffles are metal strips placed inside bioreactors to reduce vortex formation and increase aeration efficiency. They help in breaking up large gas bubbles and ensure uniform mixing of the culture medium.

What are the main types of bioreactors and their applications?

-The main types of bioreactors include continuous stirred tank fermenters, airlift fermenters, bubble column fermenters, fluidized bed fermenters, packed bed fermenters, photobioreactors, and membrane bioreactors. They are used for producing antibiotics, enzymes, biofuels, and for wastewater treatment, among other applications.

What are some limitations of using a stirred tank fermenter?

-Stirred tank fermenters have several limitations, including high shear stress, high power consumption, and the complexity of maintaining the moving internal parts, which can increase operational costs and maintenance requirements.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Media and Information Literacy: Audio Information

Perancangan Mesin | Elemen Mesin

Teori Bangunan Kapal: Topik 3 - Ukuran Utama Kapal (Ship Principle Dimension)

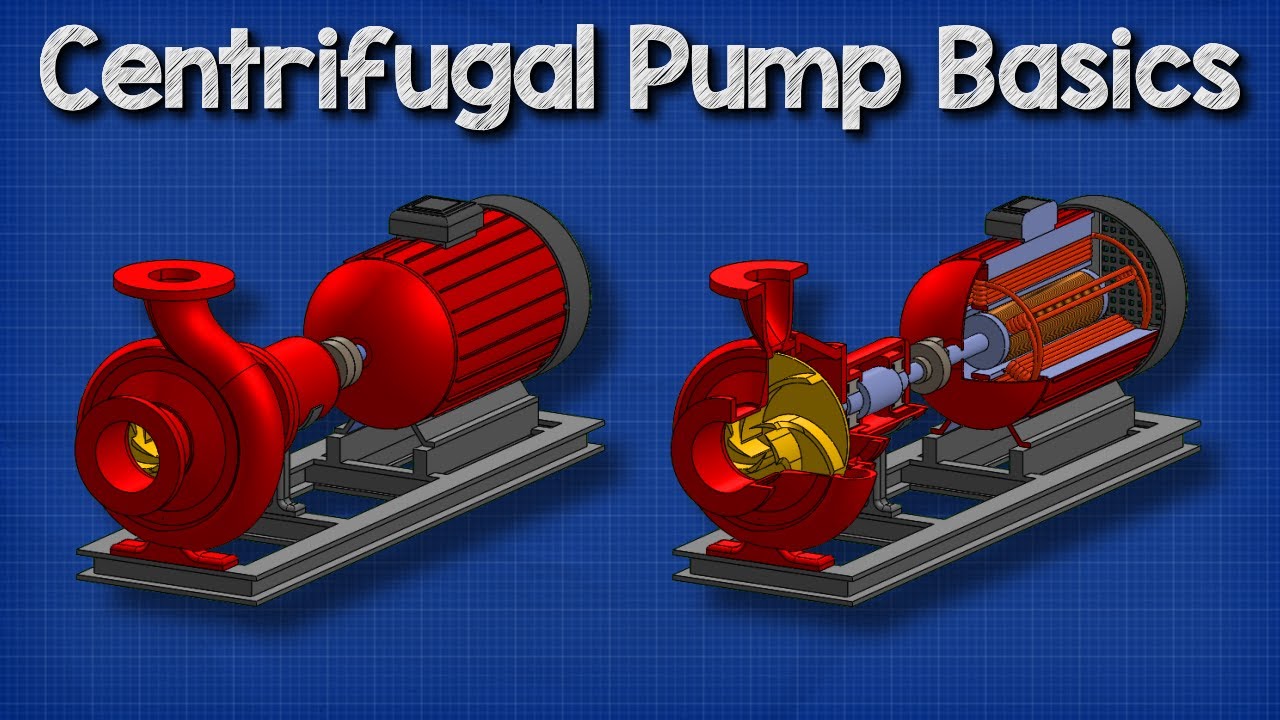

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Acid Base Theory (Arrhenius, Bronsted Lowry, Lewis)

Vulkanisme: Pengertian – Proses dan Dampaknya

5.0 / 5 (0 votes)