Bourdon Tube pressure gauge working animation

Summary

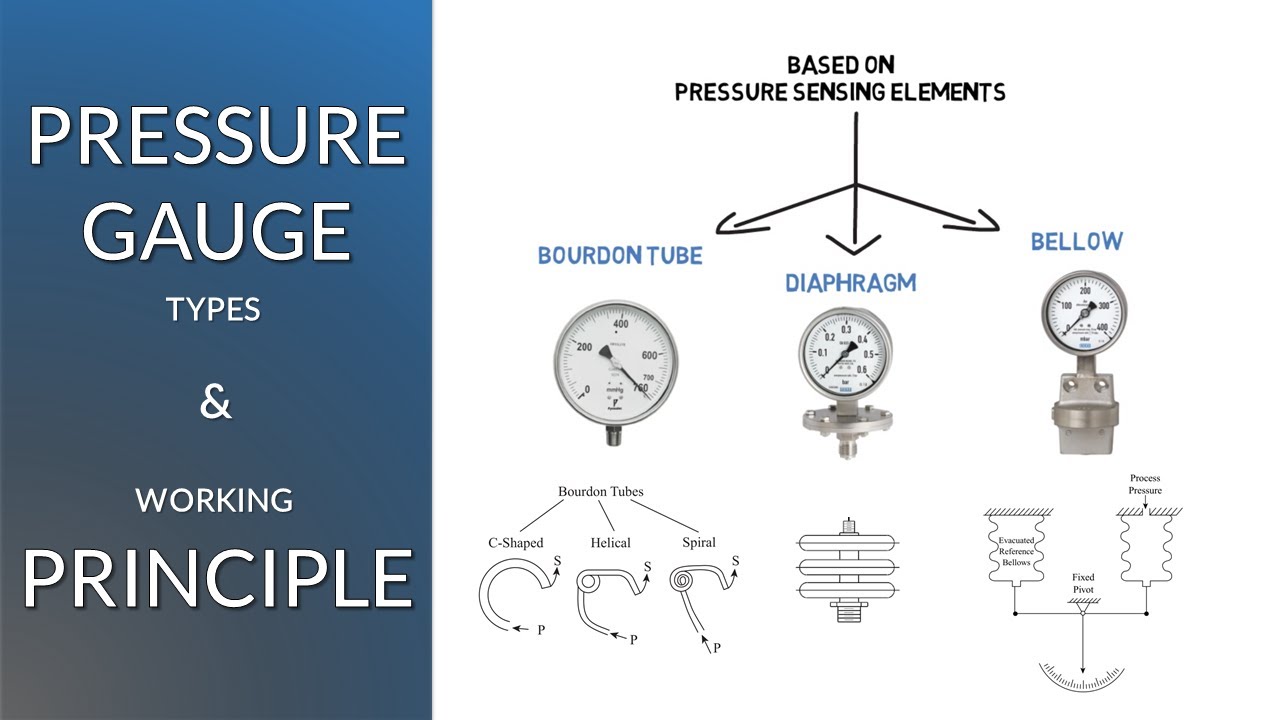

TLDRThis video explains the working principles, construction, and advantages of Burden Tube Pressure Gauges, which are mechanical instruments used to measure pressure from 0.6 bar to 7,000 bars. The video covers how the pressure causes the elastic Burden tube to deflect, operating a pointer through a linked mechanism. It also discusses the different types of Burden tubes (C-type, helical, and spiral), the use of siphon tubes to protect sensors, and the pros and cons of these gauges, including their accuracy, simplicity, and low cost, as well as their sensitivity to pressure changes and vibrations.

Takeaways

- 😀 Burden to pressure gauges are mechanical pressure measuring instruments used to measure relative pressure from 0.6 bar to 7,000 bars.

- 😀 They operate without the need for electric power, making them simple and reliable for various applications.

- 😀 The working principle of a burden tube pressure gauge involves the deflection of an elastic transducer (burden tube) in response to applied pressure.

- 😀 The deflection of the burden tube is proportional to the applied pressure when calibrated correctly.

- 😀 Burden tube pressure gauges are typically made from materials such as phosphor bronze, steel, and beryllium copper.

- 😀 The construction of a C-type burden tube consists of a long, thin-walled cylinder with a non-circular cross-section sealed at one end.

- 😀 The free end of the burden tube moves when pressure is applied, causing the connected pointer mechanism to indicate the pressure on a scale.

- 😀 Siphon tubes are often used with burden tube pressure gauges to protect the sensor from high-temperature media and reduce the effects of rapid pressure changes.

- 😀 Burden tubes are available in three shapes: C-type, helical type, and spiral type, each suitable for different applications.

- 😀 The advantages of burden tube pressure gauges include accurate results, low cost, simple construction, and the ability to be modified for electrical outputs.

- 😀 Disadvantages include slow response to pressure changes, sensitivity to shocks and vibrations, and the need for amplification due to the low displacement of the burden tube's free end.

Q & A

What is a burden tube pressure gauge used for?

-A burden tube pressure gauge is used for the pressure measurement of relative pressure, ranging from 0.6 bar to 7,000 bars.

How does a burden tube pressure gauge operate?

-Burden tube pressure gauges are mechanical pressure measuring instruments that operate without the need for electric power.

What are the main components of a burden tube pressure gauge?

-The main components of a burden tube pressure gauge include the burden tube (a long thin-walled cylinder), a light mechanism that operates the pointer, and a socket where the fluid enters the tube.

What materials are commonly used to make burden tubes?

-Burden tubes are typically made from materials such as phosphor bronze, steel, and beryllium copper.

What happens when pressure is applied to the burden tube?

-When pressure is applied, the burden tube deflects. The deflection is proportional to the applied pressure when calibrated.

How does the deflection of the burden tube result in a pressure reading?

-The deflection of the burden tube is transmitted to a segmental lever, which then moves a pointer over a scale, providing a pressure reading.

What is the purpose of the siphon tube in real-life applications of burden tube pressure gauges?

-The siphon tube is used to protect the pressure sensor from high-temperature media, like steam, and helps reduce the damaging effects of rapid pressure changes.

What types of burden tube shapes are commonly used?

-Burden tubes are generally made in three shapes: C-type, helical type, and spiral type.

What are the advantages of using burden tube pressure gauges?

-Some advantages include accurate results, low cost, simple construction, the ability to give electrical outputs, safety even at high pressures, and high accuracy, especially at high pressures.

What are the disadvantages of burden tube pressure gauges?

-Disadvantages include slow response to pressure changes, susceptibility to hysteresis, sensitivity to shocks and vibrations, the need for amplification due to low displacement, and their unsuitability for precision measurement.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pressure Gauge Types and Working Principle | Simple Science

4.3d Measuring Pressure: Manometer 'U Tubes' and Barometer Pipes | AS | Cambridge A Level Physics

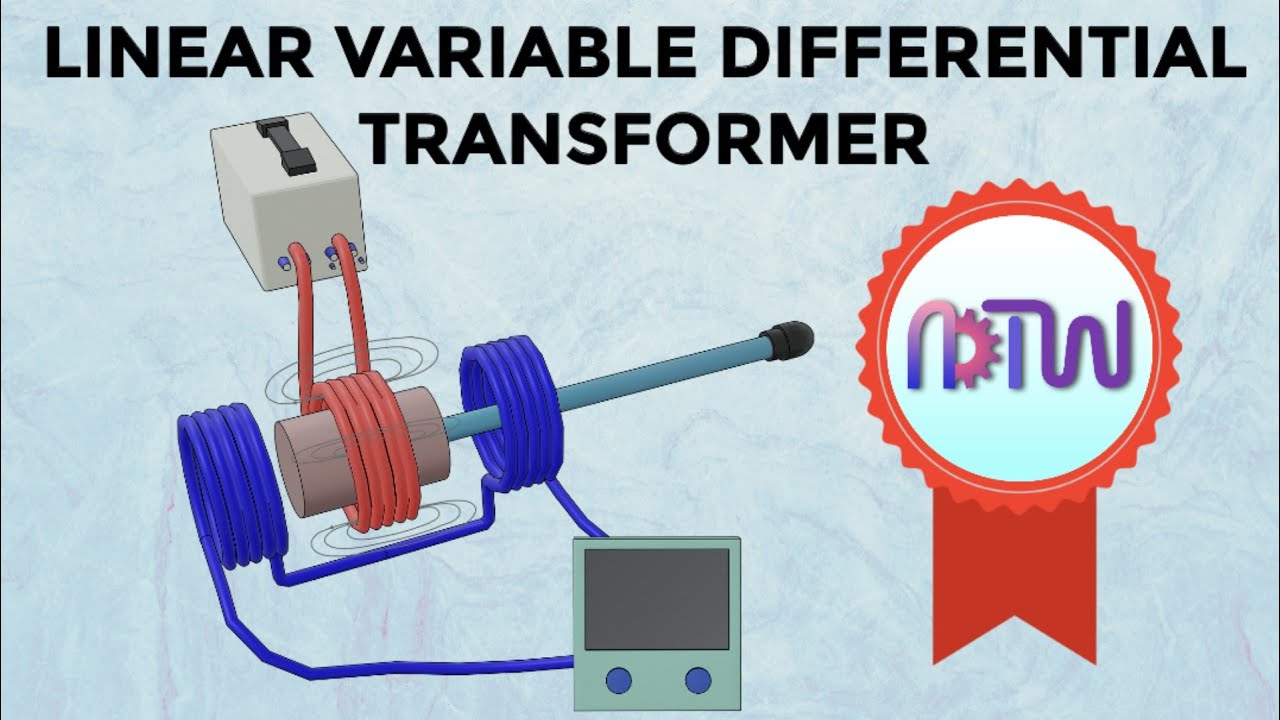

LVDT - Linear Variable Differential Transformer or Transducer Working

Episode 14: Homemade Barometer

Prinsip Hidrostatika | Fluida | Part 1 | Fisika Dasar

24 Februari 2025

5.0 / 5 (0 votes)