LVDT - Linear Variable Differential Transformer or Transducer Working

Summary

TLDRThis video explains the working principle, construction, and applications of the Linear Variable Differential Transformer (LVDT), an electromechanical sensor used to measure linear displacement. It details how an LVDT converts linear motion into an electrical signal, with examples of different core positions affecting the output voltage. The video highlights the advantages such as high accuracy, sensitivity, and lack of mechanical friction, alongside limitations like sensitivity to magnetic fields. Applications range from measuring force and pressure to providing feedback in hydraulic systems. The video aims to provide a clear understanding of LVDT’s operation and uses.

Takeaways

- 🎶 LVDT (Linear Variable Differential Transformer) is an electromechanical transducer used to convert linear motion into a proportional electrical signal.

- 🔍 LVDT offers high accuracy, good sensitivity, high resolution, and minimal mechanical friction, making it ideal for measuring linear displacement.

- ⚙️ The construction of an LVDT includes three coils: a primary coil in the center and two secondary coils on either side, with equal turns but opposite orientation.

- 🧲 A movable soft iron core inside the transformer affects magnetic coupling between the primary and secondary coils to measure displacement.

- ⚡ The LVDT operates by inducing voltage in the secondary coils when AC current is applied to the primary coil, with the net emf determined by the position of the core.

- 🏞️ Case 1: When the core is in the center, equal voltage is induced in both secondary coils, canceling each other out, resulting in zero output voltage (null position).

- ⬅️ Case 2: When the core moves to the left, more flux links with the left secondary coil, producing a positive output voltage.

- ➡️ Case 3: When the core moves to the right, more flux links with the right secondary coil, producing a negative output voltage.

- 📊 LVDT has high displacement measurement range, no frictional losses, high sensitivity, and low hysteresis, leading to high accuracy and repeatability.

- 🛠️ LVDTs are used in various applications like measuring force, weight, pressure, displacement feedback in hydraulic systems, and medical brain probing.

Q & A

What is an LVDT?

-An LVDT, or Linear Variable Differential Transformer, is an electromechanical transducer used to convert the linear motion of an object into a proportional electrical signal.

What makes LVDTs preferable for measuring linear displacement?

-LVDTs are preferred for measuring linear displacement due to their high accuracy, high resolution, good sensitivity, and relatively zero mechanical friction.

How is an LVDT constructed?

-An LVDT consists of a cylindrical transformer with three coils: a primary coil at the center and two secondary coils on either side of the primary. These secondary coils have an equal number of turns but are wound in opposite directions. A movable soft iron core inside the transformer affects the magnetic coupling between the primary and secondary coils.

What role does the soft iron core play in the LVDT's operation?

-The soft iron core slides within the cylindrical transformer and affects the magnetic coupling between the primary and secondary coils, determining the amount of voltage induced in each secondary coil based on its position.

What is the principle of operation of an LVDT?

-An LVDT operates by inducing an alternating current (AC) in the primary coil, which generates voltages in the secondary coils according to Faraday's Law of Induction. The difference in voltage between the two secondary coils, due to their opposite winding, is proportional to the core's displacement.

What happens when the core is at the center of the LVDT?

-When the core is at the center, equal voltage is induced in both secondary coils (S1 and S2), but since they are of opposite magnitude, the net output voltage is zero. This position is called the null position.

What is the output voltage when the core is to the left of its center position?

-When the core is on the left-hand side, more magnetic flux links with coil S1, causing a higher voltage in S1 than in S2. The net output voltage will be positive.

What happens when the core moves to the right-hand side?

-When the core is on the right-hand side, more magnetic flux links with coil S2, resulting in a higher voltage in S2 compared to S1. The net output voltage will be negative.

What are some advantages of using LVDTs?

-Advantages of LVDTs include a high range of displacement measurement, no frictional losses, high accuracy, high sensitivity, low hysteresis, and rugged construction. Additionally, LVDTs do not require further amplification due to their high output.

What are some limitations of LVDTs?

-Limitations of LVDTs include their sensitivity to stray magnetic fields, the need for large displacements to produce noticeable differential outputs, and their susceptibility to temperature changes and vibrations.

What are common applications of LVDTs?

-LVDTs are used in various applications such as force, weight, and pressure measurement, brain probing in medical applications, providing displacement feedback in hydraulic systems, and measuring the distance between approaching metals during friction welding.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How LVDT Works | Construction and Working

What is RVDT?

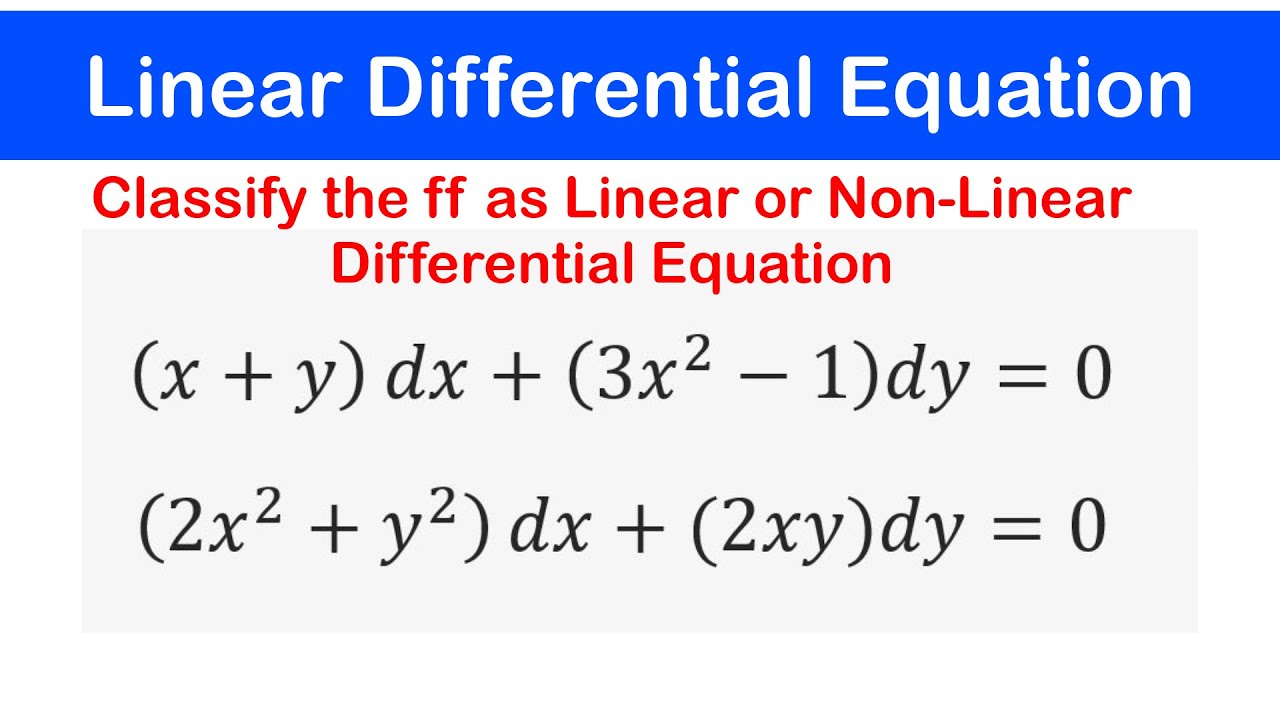

🔵03 - Linear and Non-Linear Differential Equations: Solved Examples

How a Rheostat works - Step by Step & its different applications

PERBEDAAN REGRESI LINEAR SEDERHANA DAN REGRESI BERGANDA

Accelerometer vs. Gyroscope - What's the Difference Between These Popular Sensors?

5.0 / 5 (0 votes)