What is Injection Molding and How Does it Work?

Summary

TLDRInjection molding is a manufacturing process used to produce high volumes of identical plastic parts by injecting molten polymer into a custom mold. It offers speed, cost efficiency, and the ability to work with over 25,000 materials, making it ideal for projects requiring large-scale production or complex shapes. Though the initial mold design can be expensive, the process is economically viable for runs of 500 units or more. The machine involves three main units: injection, clamping, and molding, which work together to create strong, durable parts with tight tolerances, typically within a 6-10 week turnaround.

Takeaways

- 😀 Injection molding is a manufacturing process that produces identical plastic parts by injecting molten plastic into a mold.

- 😀 The process involves melting polymer granules and injecting the liquid plastic into a mold where it cools and solidifies.

- 😀 Injection molding is faster and more cost-efficient than other processes like CNC machining and 3D printing, especially for high-volume production.

- 😀 There are over 25,000 materials available for injection molding, providing vast material flexibility for different parts.

- 😀 Injection molding can produce millions of identical parts with tight tolerances, strong durability, and excellent repeatability.

- 😀 The main economic challenge is the high initial cost of mold design and manufacturing, which can range from $5,000 to $100,000.

- 😀 Injection molding becomes cost-effective when producing over 500 units due to the high upfront tooling cost.

- 😀 Design changes after the mold is created can be expensive and time-consuming, requiring the creation of a new mold.

- 😀 Typical injection molding lead time is between 6 to 10 weeks, including mold creation and production.

- 😀 Injection molding is ideal for projects requiring high-volume production, complex designs, metal-to-plastic conversions, or superior surface finishes.

- 😀 Injection molding machines consist of three main parts: an injection unit, a clamping unit, and a mold, all working together in a fast, repeated cycle to produce parts.

Q & A

What is injection molding?

-Injection molding is a manufacturing process that produces identical parts by injecting molten plastic into a mold. The process involves melting polymer granules, injecting them under pressure into a mold, and allowing the plastic to cool and solidify.

What are the advantages of injection molding over other manufacturing processes?

-Injection molding is faster and more cost-effective for producing plastic parts, especially when producing high volumes. It also allows for tight tolerances, high durability, and an excellent surface finish, making it ideal for mass production.

What is the economic restriction of injection molding?

-The main economic restriction is the high initial cost of tooling design. Custom molds need to be created for each part, which can cost between $5,000 and $100,000. This makes injection molding more economically viable for production runs of over 500 units.

How long does the typical turnaround time for injection molding take?

-The typical turnaround for injection molding is between 6 and 10 weeks, with 4 to 6 weeks for mold manufacturing and 2 to 4 weeks for production and shipping.

When should injection molding be considered for a project?

-Injection molding should be considered for projects requiring large annual production volumes, complex designs, metal-to-plastic conversions, or projects with stringent surface finish requirements. It is also ideal when the design is likely to remain stable or change incrementally.

What are the main parts of an injection molding machine?

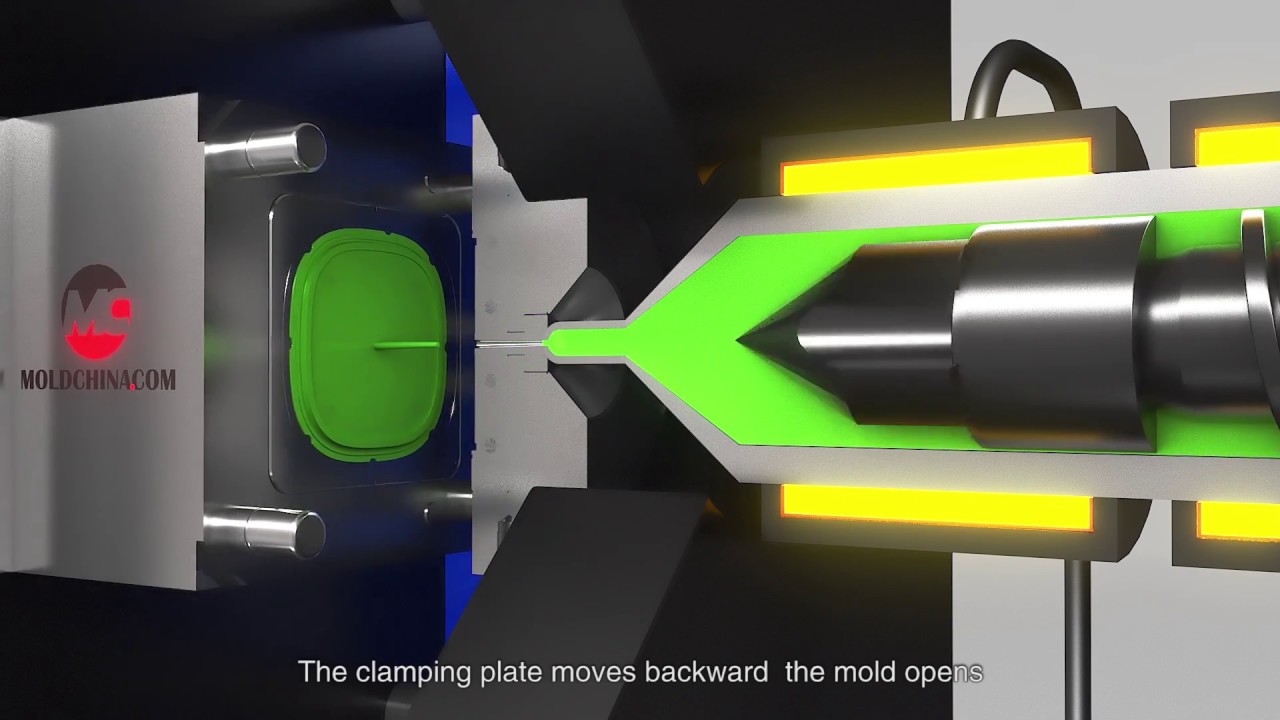

-An injection molding machine consists of three main parts: the injection unit, the clamping unit, and the mold. The injection unit melts and injects the plastic, the clamping unit controls the mold, and the mold shapes the plastic into the desired part.

How does the injection unit of an injection molding machine work?

-The injection unit includes a hopper to feed plastic granules, a barrel to melt and mix the plastic, a reciprocating screw to move the plastic towards the mold, and a nozzle to inject the melted plastic into the mold.

What role does the clamping unit play in the injection molding process?

-The clamping unit holds the mold in place and ensures it opens and closes at the correct times during the injection molding process, maintaining the integrity of the mold and the part being produced.

What are side action cores and why are they used?

-Side action cores are moving elements that enter the mold from the top or bottom to create parts with overhangs, cavities, or holes. They are used when the mold requires more complex geometries than a simple straight pull mold can accommodate.

How long does an injection molding cycle take?

-An injection molding cycle typically takes between 30 to 90 seconds, depending on the size of the part. This rapid cycle time allows for fast production of high volumes of parts.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)