Como funciona una inyectora de plastico

Summary

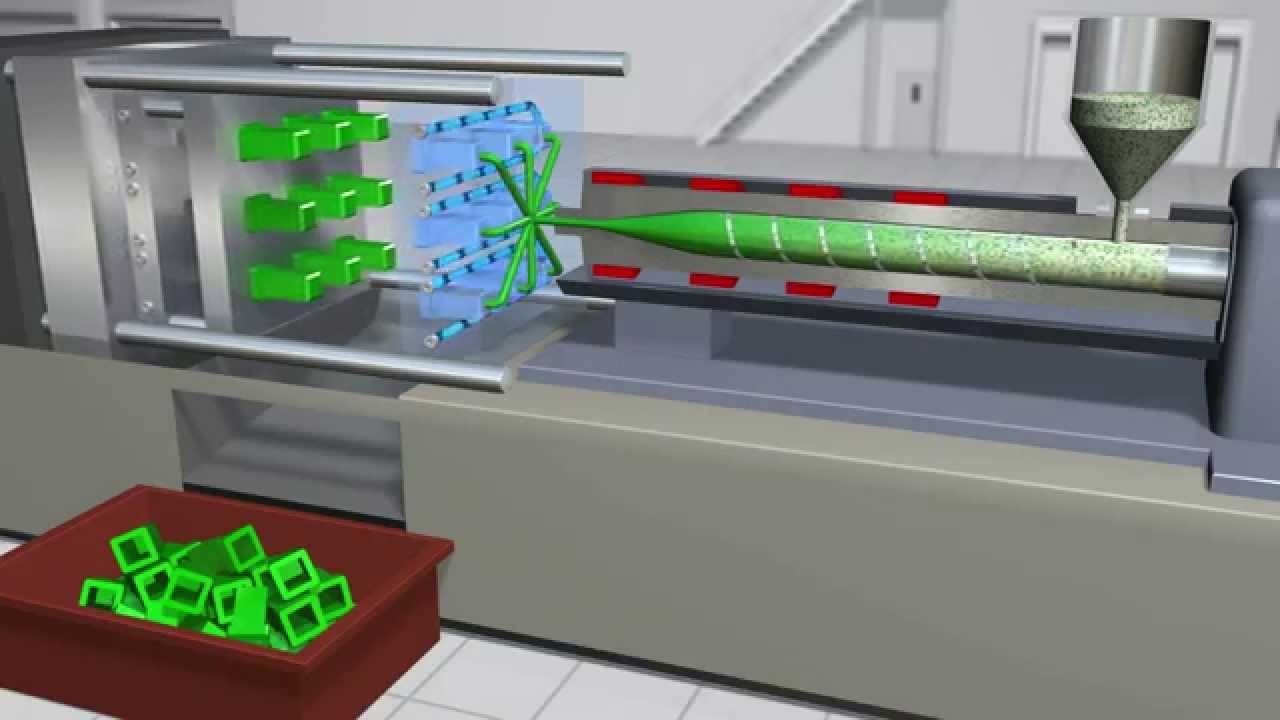

TLDRThis video provides an insightful look into the process of plastic injection molding. It explains the role of a plastic injection machine, which uses a hydraulic system and powerful pistons to melt and inject plastic into molds to create various products like containers and packaging. The process involves several steps, including loading plastic pellets, melting them, injecting the material into a mold, and cooling the product. The machine’s control system regulates temperature and sequence, ensuring precision in creating high-quality molded products.

Takeaways

- 😀 The script discusses the process of plastic injection molding, which is used to create various plastic products such as cups, containers, and butter packaging.

- 😀 The machine involved in this process is a plastic injection machine that consists of a motor, hydraulic pump, and powerful pistons that carry out different functions.

- 😀 One of the pistons controls the opening and closing of the platina, where the mold for each product is mounted.

- 😀 Another hydraulic piston is responsible for injecting melted plastic into the mold through a thick steel tube known as the 'cañón'.

- 😀 A hopper, where plastic granules are initially deposited, feeds the plastic into the cañón for continuous production.

- 😀 The machine includes a control console where operators can monitor and adjust the temperature through controllers, which regulate electrical resistances that maintain the necessary heat for the process.

- 😀 The machine's operating cycle involves several steps, including loading the cañón with plastic granules, melting them, and injecting the melted plastic into the mold.

- 😀 The mold consists of two halves that have cavities where the melted plastic is injected to form the product, with channels designed to avoid blockages during cooling.

- 😀 After injection, the plastic cools in the mold to solidify and form the product, which is removed once it has hardened.

- 😀 The script concludes with a brief summary of the plastic injection molding process, highlighting the steps and the machine's functionality, with a call to subscribe to the channel for more information.

Q & A

What is the primary function of the injection molding machine described in the script?

-The primary function of the injection molding machine is to inject molten plastic into a mold to form various plastic products, such as containers, cups, and packaging.

What are the main components of the injection molding machine?

-The main components of the injection molding machine include a motor, a hydraulic pump, pistons, a mold platen, a cannon (for holding molten plastic), a hopper for plastic granules, and a control console.

How does the hydraulic system contribute to the injection molding process?

-The hydraulic system drives powerful pistons within the machine. One piston controls the opening and closing of the platen, while another piston injects the molten plastic into the mold.

What is the role of the hopper in the injection molding machine?

-The hopper holds and feeds plastic granules of the correct type, color, and texture into the cannon, where they are melted and injected into the mold.

What does the control console manage during the injection molding process?

-The control console manages the temperature via pyrometers, regulates the heat required to melt the plastic, and controls the sequence of operations and the duration of each cycle in the machine.

What happens during the 'charge' phase of the cycle?

-During the charge phase, the plastic granules are loaded into the cannon, where they are melted by surrounding heating elements to form a thick liquid, preparing the material for injection.

Can you explain the 'injection' phase in the process?

-In the injection phase, the molten plastic is injected into the mold under high pressure until it fills the mold cavity. This phase ensures the mold receives the correct amount of plastic to form the product.

Why is the cooling phase necessary in the injection molding process?

-The cooling phase is crucial because it allows the molten plastic to solidify inside the mold. This hardening process is necessary for the product to retain its shape when removed from the mold.

What is the purpose of the 'screw head' piston in the injection molding machine?

-The screw head piston, which has a screw-like shape, rotates and pushes the plastic granules through the cannon, helping to load the cannon and mix the plastic before it is melted and injected into the mold.

What is the significance of the temperature control in the injection molding process?

-Temperature control is critical to maintain the right viscosity of the molten plastic. If the plastic is too hot or too cold, it can result in defective products or an incomplete molding process.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

INJECTION MOLDING - DEFINISI, CARA KERJA, DAN BAGIAN-BAGIAN MESIN INJECTION MOLDING

O básico do processo de injeção de plásticos

How Plastic Products are Made | The Injection Molding Process

Plastic Processing Overview

How Things Are Made | An Animated Introduction to Manufacturing Processes

Introduction Of Injection Moulding Machine

5.0 / 5 (0 votes)